Thanks guys for all the encouragement!

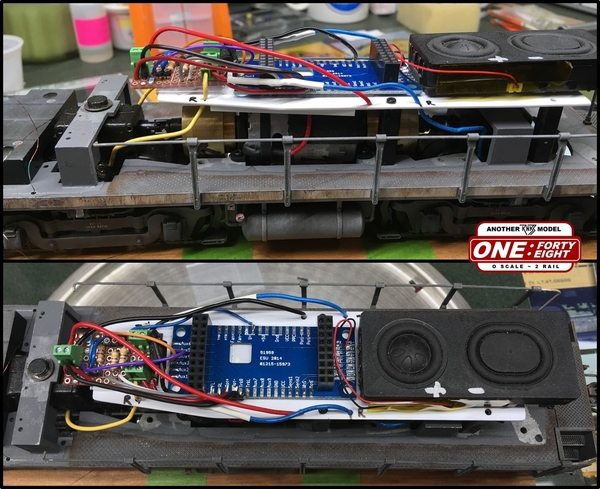

Greg, I used a Tang Band 1925S dual speaker. A search of this board will find a whole thread about these speakers to include some sound clips. I have heard that ESU is now stocking them also. The ESU Loksound V4 and V5 decoders drive these easily, and the sound is pretty awesome.

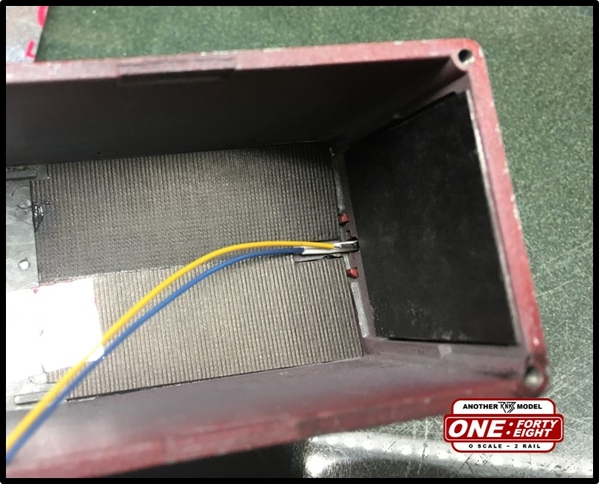

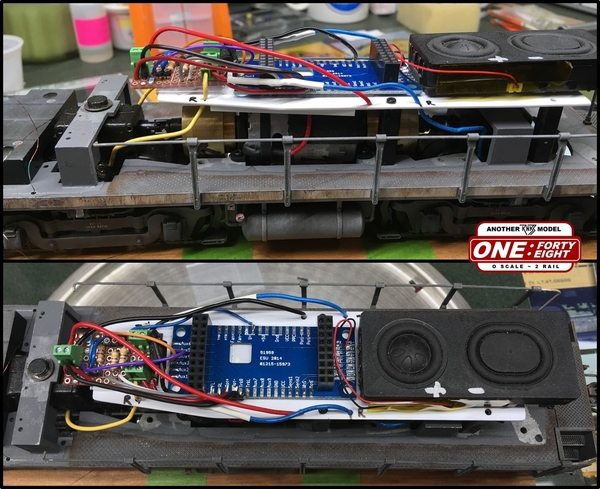

Here is a couple shots of all the magic electronics in my SW1200. I basically copied the installation form my friend Bob Sobol (search this website for his name...there are several threads about his work). The speaker is up font; firing up. The decoder goes in the middle (not actually shown) and is attached to a "mother board" to make all of the wiring connections. At the back is a homemade board that holds all of the resistors for the LED lights, multi pin connectors for the light harnesses, and screw terminals to plug in the truck and motor wires.

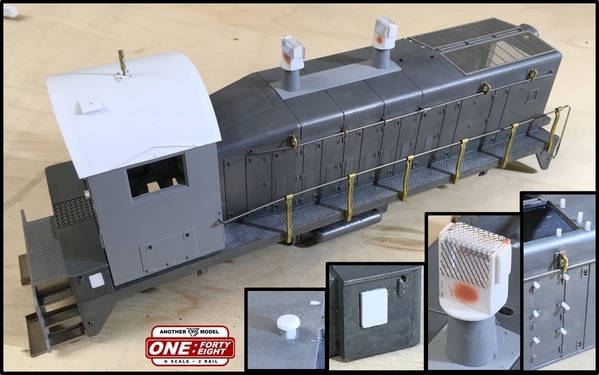

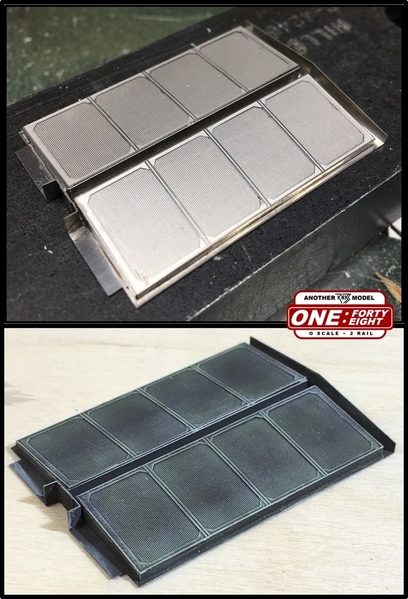

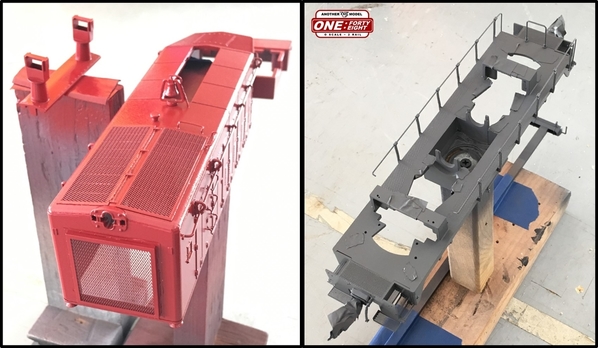

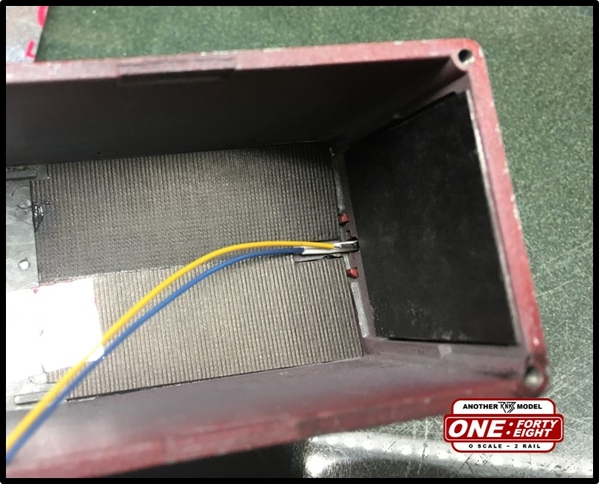

Earlier in this thread I showed the KV Models etched radiator core designed to fit this model. After some discussion and thought, I have decided to forgo the excellent etching due to concern that it will block sound. In its place, I made a fake core from some textured dark colored paper. I simply drew the core supporting structure on the paper with a silver Sharpie marker and taped it inside the shell. We'll see if it work! As of now, it at least looks good!