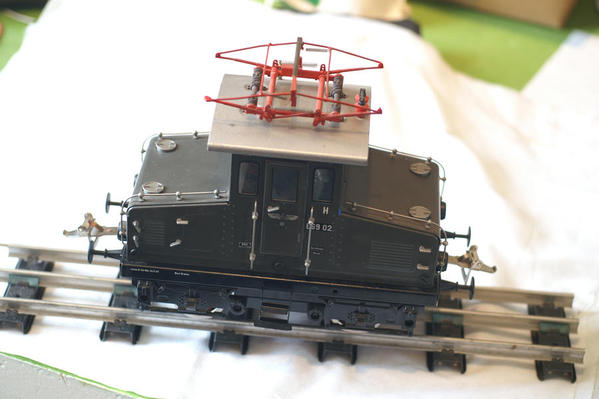

While some of you guys have been messing around getting Dorfan engines back up and running, I've been tackling a Marklin Steeple Cab project. This is a #54204 from the Marklin "Maxi" line of all-metal tinplate from the 1990's, made in 1 Gauge for "G Scale", 2-rail. I picked it up cheap because the motor was dead in the water, and also the pantograph on the roof had been scrunched and was no longer functional. Other than that, the tin cab and frame were pristine! A little soldering and touch-up made the pantograph presentable:

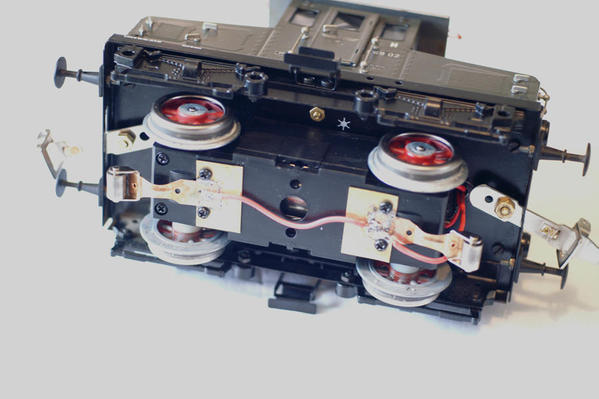

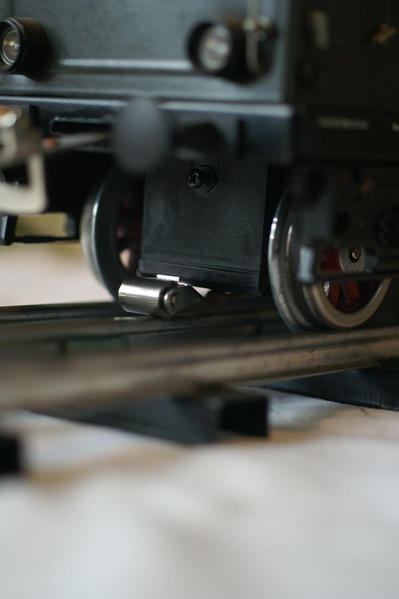

1 Gauge / G Scale is of course 1-3/4" gauge, while Standard gauge is 2-1/8". Since the motor on the Marklin was dead anyway, I swapped it out for a USA Trains motor block that I have found converts easily to SG. It's a great motor with both axles powered and a lot of torque, and the axles are long enough to accomodate the wider gauge. One of it's problems for SG use is how low in the belly it is, since it was not designed to run over a center third rail. I put some larger diameter drivers on it, but there was still little room for pickup rollers. Had to split a set and mount them on the ends of the block so they had headroom:

I was able to cram a Williams reversing board into the cab along with a couple pounds of lead weight to give the little thing some traction; it's only 9-1/2" long including the buffers. And the cab interior is detailed nicely, so the lead and circuit board all had to go in the little motor compartments on each end.

Here's some video of it pulling a couple cars I had; they are a little beat up and rusty in spots, but they're interesting. Made in Germany by Bing in the 1920's, but lettered for the French market; originally in 1 Gauge, with standard gauge trucks under them, they make a pretty good match for the Marklin Steeple Cab, the buffers even line up. Got some pics in of my Euro stations to complete the look.

Don't know what's up with the LED lights on the steeple cab, they were working just before I closed the cab up, they aren't any more. Have to take the cab apart again sometime, no small project.

Enjoy!