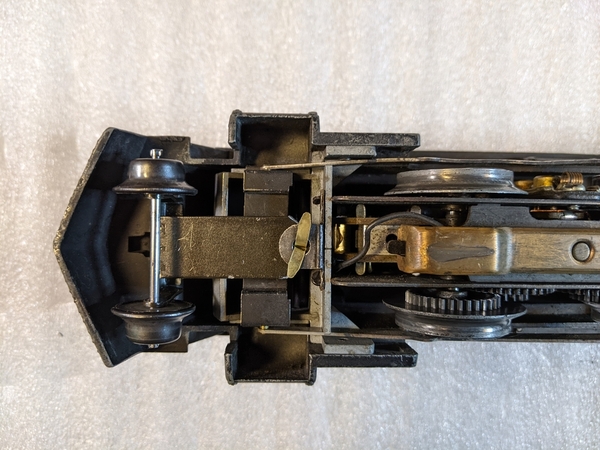

I have several Marx 666s locomotives. They are probably my favorite 2-4-2 locomotives. They are reliable, and pretty decent pullers too. Recently I acquired a couple of 666s that were both missing the front trucks. I bought a couple of "reproduction" front trucks, and installed them, only to discover that they were derailing the locomotive at almost every curve - on 027 or standard 0 gauge curves. On closer examination, I found that the "repro" truck bracket was longer than the original truck bracket, and the wheels were burlier than the originals. The repro truck wheels were rubbing up against the inside surface of the cowcatcher and were also interfering with the handrail which pokes through the top of the cowcatcher. What a disappointment.

Replies sorted oldest to newest

That's a shame Mike! Can you return them and get your money back? I'm glad you posted on here. If people do their homework, that vendor is going to have to eat his inventory (and well he should!) A major sore point for me is when a product does not live up to its promise. And that seems to happen too often in O gauge!

@Ted S posted:That's a shame Mike! Can you return them and get your money back? I'm glad you posted on here. If people do their homework, that vendor is going to have to eat his inventory (and well he should!) A major sore point for me is when a product does not live up to its promise. And that seems to happen too often in O gauge!

The vendor (The Robert Grossman Co.) is very reputable and is going to refund my money.

I am disappointed though because I am gifting these locomotives and I wanted them to be fully restored.

The locomotives can be operated without the front trucks.

I made some field modifications that have greatly improved the performance of the reproduction front trucks. As I mentioned, their were dimensional variances between the original and the repro trucks, and some of these variances were creating interferences and locomotive derailments.

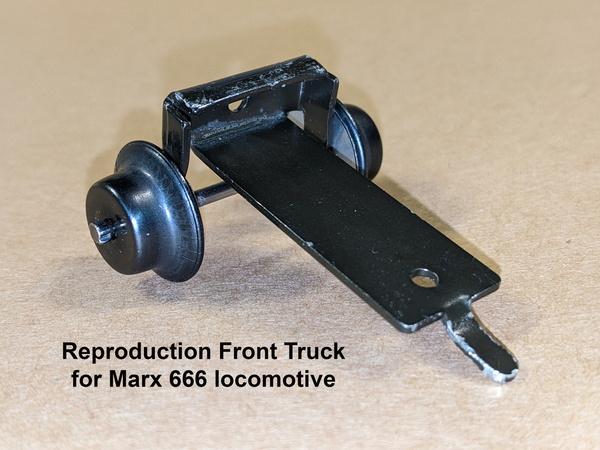

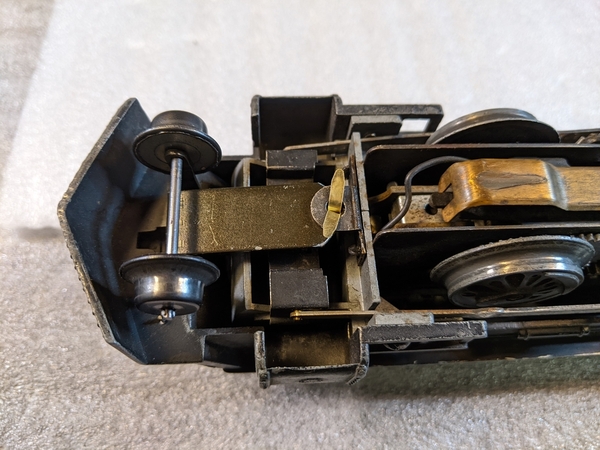

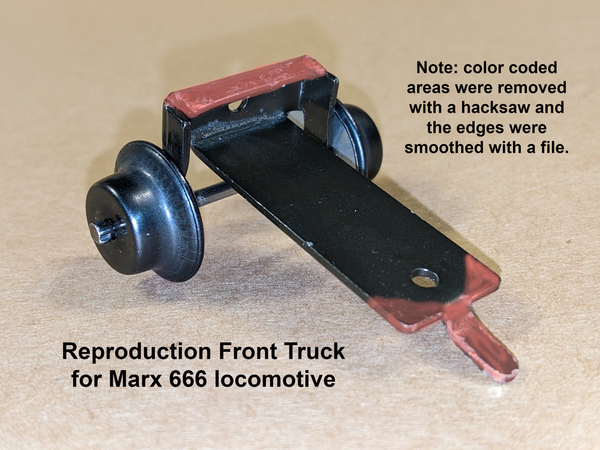

Here are a couple of pictures of the repro truck:

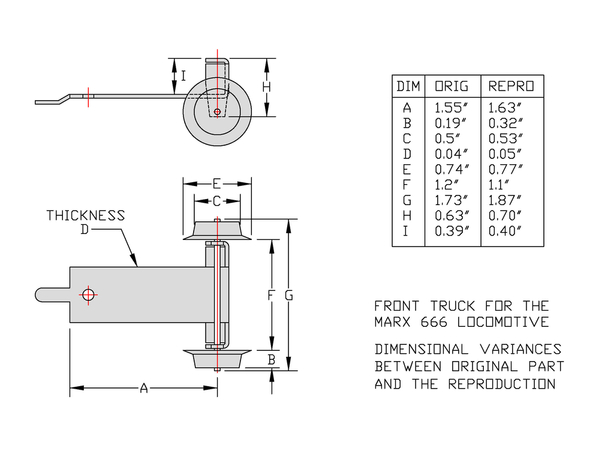

Below is a comparison of some of these critical dimensions:

As I had mentioned, the longer A dimension and the larger B & G dimensions of the repro truck seemed to be the cause of the derailment problems.

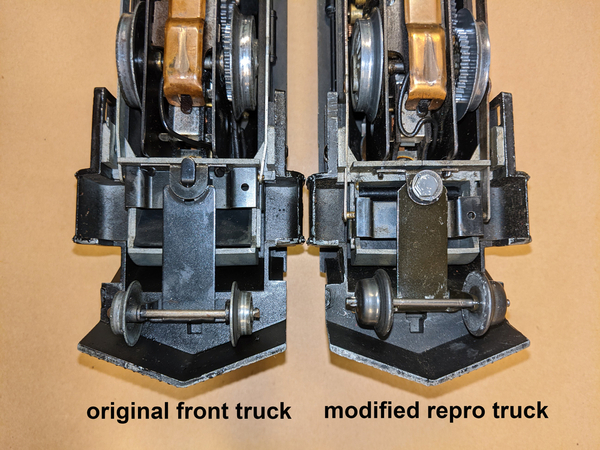

In order to fix this, I cut off the tab on the left above, chamfered the corners, and used the through hole to fasten the truck to the locomotive's mating hole using a machine screw (#4-40 X 3/8" slotted pan-head) with a #4 washer and a #4 hex nut. I then put a dab of JBWeld on the nut to keep it in place.

I can now operate the Marx 666 locomotive with the repro front truck. The large wheels no longer rub against the inside of the cowcatcher, and the truck assembly can swivel freely without hitting the handrail stubs which poke through the top of the cowcatcher. However, the new front truck is very intolerant of tubular track imperfections - mainly on curves. It's very difficult to nail down a uniformly flat, level, tubular track. After I made the front truck modifications, I found one curve that was still causing the new repro truck to derail. I added one additional hold-down screw on this curved track section, and that solved the derailment problem.

In my opinion, the best solution, by far, would be for the part supplier to make the repro truck exactly like the original.

Attachments

Here is a picture of a Marx 666 with the original front truck:

Here is a short video of the Marx 666 locomotive with the new repro front truck.

Attachments

I'm glad that you're getting your money back, and I appreciate you sharing your solution. I've heard of Robert Grossman. One would think that if you're going to use machine tools to mass-produce a "repro" item, you would start with a valid original!

Is the repro front truck taking weight off of the driving wheels? It seems like your loco was struggling to pull that cut. Dirty track? Or the boxcar axles need a drop of oil? Thanks for sharing.

@Ted S posted:I'm glad that you're getting your money back, and I appreciate you sharing your solution. I've heard of Robert Grossman. One would think that if you're going to use machine tools to mass-produce a "repro" item, you would start with a valid original!

Is the repro front truck taking weight off of the driving wheels? It seems like your loco was struggling to pull that cut. Dirty track? Or the boxcar axles need a drop of oil? Thanks for sharing.

Normally I get better traction with the 666s. This one is slipping a bit. Probably because I sprayed the sticking E-unit with some WD-40, and I think the wheels were slickened with overspray.

Here is another video of the 666 pulling 12 Lionel cars.

Attachments

As a follow-up, I just thought I'd mention that I have discovered a much better way to fasten my repro front truck. I am using an ordinary brass paper clasp - the ones with the brass button and the two fingers that you thread though the hole, then spread/bend the fingers over. Below are a couple of pictures. This has worked really well, without any derailments on 027 or 031 gauge curves. The front truck needs to be loose and floppy - both side-to-side and up-down. If it's not free to move about, it will derail.

Attachments

Thats kind of surprising given that I had ordered the same truck a year or so ago and had no problems with it. May be a recent problem with production??

@Kelpieflyer posted:Thats kind of surprising given that I had ordered the same truck a year or so ago and had no problems with it. May be a recent problem with production??

Occasionally original parts are available - and the original trucks work really well. If you are lucky, the supplier will send you the original truck. The reproduction trucks though are really problematic as I have detailed above.

Another follow-up. I had some traction problems with two of my 666s that had my field-modified repro front trucks. After a closer examination, I realized the "H" dimension of the repro trucks was the culprit. The height "H" (see my drawing above) was causing the front truck to carry some of the weight of the locomotive shell. This transfer of weight from the drive wheels caused them to slip - and it was especially noticeable on curves. So I used a hacksaw and a file to reduce the "H" dimension so that it would be about the same dimension as the original truck. That solved the problem.