This will be an ongoing thread.

I saw this kit in the Korber booth at York. It is a new combination of parts from the TT and MRS modular systems that builds a rail/truck transfer building. I thought it was a neat concept, so it came home with me.

It is on the Korber site here: https://mrmuffinstrains.com/pr...=54f7d135e&_ss=r

Disclaimer 1a: I bought the kit Thursday, took it to my hotel in York to read the directions and discovered the kit to be missing the 3 vertical pilasters. This is not a "problem" as I went back on Friday, and it was discovered that all of the kits were missing them. One of the Muffins is going to send them to me.

I presume that the Muffins are going to check these kits when they get home and fix the parts packing issue.

As I had another MRS kit here, I have momentarily swiped the pilasters from that kit to build this one, and will replace them with the ones that come in the mail shortly, so this may only be an issue if you bought one at York.

Disclaimer 1b: The kit has parts you dont need. Packed in the kit, are the cornices (uppermost wall sections) for the MRS system. You have 2 options:

1. If you want to build the kit as intended, throw them away so you dont make the "autopilot" construction mistake I did.

2. If you want to bash this into a building that includes more MRS components (i.e. a building that has a truck dock addition made from TT walls,) hang onto them. You'll see why below and will need the pilaster foundation parts too.

The kit instructions are not bad. There's a few things that could stand to be clarified, so as I figured them out, those steps are depicted below, along with a few tweaks to the kit.

The kit has 3 truck docks, I only used 2. I had some parts left over from another TT kitbash, so I swapped a truck dock for a blank wall. The kit also comes with 3 people doors, I only used 2, and traded the 3rd door for a window.

The TT walls are all the same width, so the kit builds as 5 walls wide, and 4 walls deep, with 2 MRS sections making up the 4th (back) wall. The systems are dimensionally close, but not quite. You do need to trim the ends of the MRS sections for this to go together right (more on this below). No one should be intimidated by this, precision not necessary.

First step is to clean up all the edges. There's a fair bit of sprue bits and flash that needs to be cleaned off so everything butts up nicely.

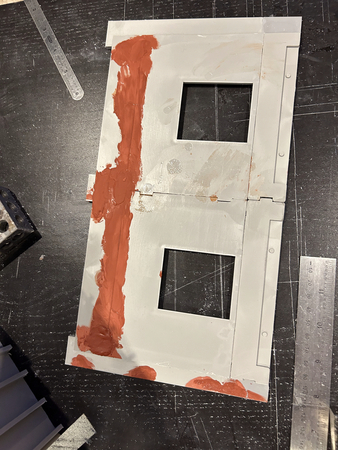

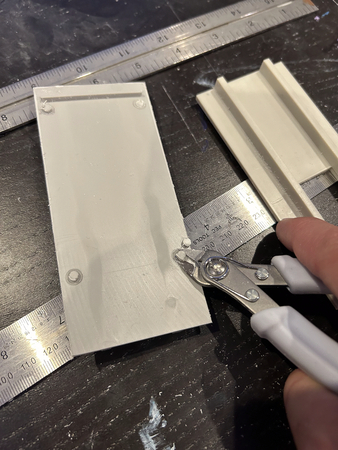

I set the front wall up with 2 windows, a door and 2 blanks, so that there would be an office. One side wall includes the 3rd window and 3 blanks. The truck docks are on the opposite side, along with a door for the shipping department, and a blank wall. It struck me as odd to have the truck dock being the end piece, as structurally, it left no room for "framing" the corner of the building. So I split a blank wall in half, right up the middle. This was done with a zona saw and a set of calipers. It’s right around 1.2" per side. Doing this does 2 things. First, it gets the dock out of the corner and second, it gets the dock centers closer to the standard 12 foot spacing. You end up with about 14 scale feet by splitting the section.

The important thing to line up isnt the top or bottom, its the rail for the roof on the back of the panels. Use a sprue cutter and trim off the bulk of these nubs so you you can glue everything up. Perfection and total flatness not needed yet.

I used a pair of rulers to line everything up. I lined up the roof rails against the top ruler, the bottom one is just a spacer so the walls sit level and off the table. Faller Expert is my glue du jour.

Once you glue up the front wall, measure it:

I came up with 10 and 29/32, but depending on how much cleaning and filing you do, you might get a slightly different number.

Assemble the 2 MRS sections and glue in the center pilaster. Transfer your measurement from above to the MRS sections. You'll find that essentially, you need to cut the tabs off the ends. Remove the red areas. (refer to disclaimer 1b above... I built this on autopilot without looking at the diagrams in the directions because they gave me parts. You shouldn't use the top cornices). Continue trimming until the MRS sections are narrower than the front wall. Its ok if you go a little overboard, just dont leave too much. The reason is that the front and back walls are glued inside the sidewalls. So if the back wall is too wide, it wont fit, and once you glue the side pilasters on, trimming will get much more difficult.

Once happy, glue the side pilasters on (again, without the cornice, and without the foundation pilasters).

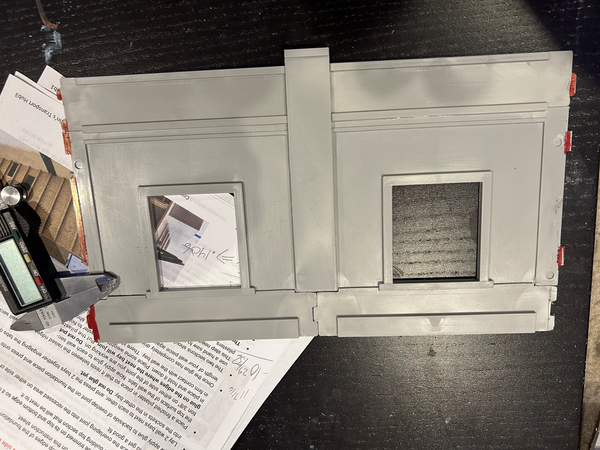

All 4 walls assembled. At this point, since you lined up the roof shelf, you can file up the tops and bottoms of all the walls so they're level.

Take the opportunity to do some body work and fill in the mold gates and gaps in the back if the MRS walls. Depending on how you put the building on the layout, you might see the back side. I used Bondo spot putty. Let dry and sand. If you dont use the cornices, you dont need this much filler (no horizontal joint above the roof line).

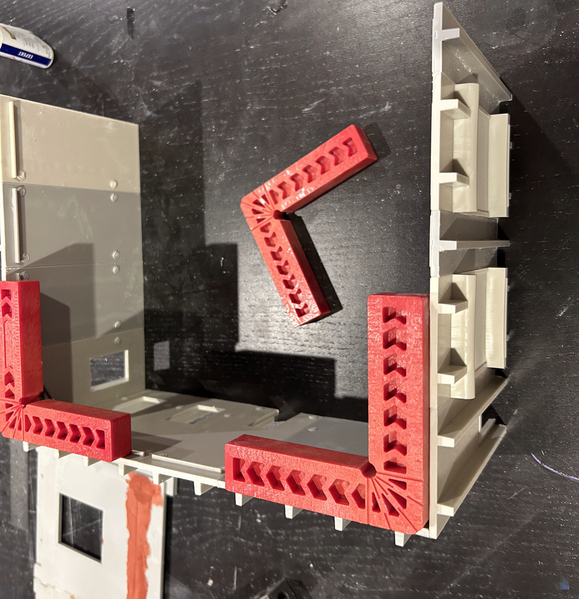

Assemble all the TT walls first. Use many right angle devices.

Last wall in is the MRS wall. If you trimmed it right, then it should fit inside the side walls. Glue the back of the side pilasters to the ends of the sidewalls (this is why your trimming can be imprecise, the wall sections just need to fit in the gap). Use squares again.

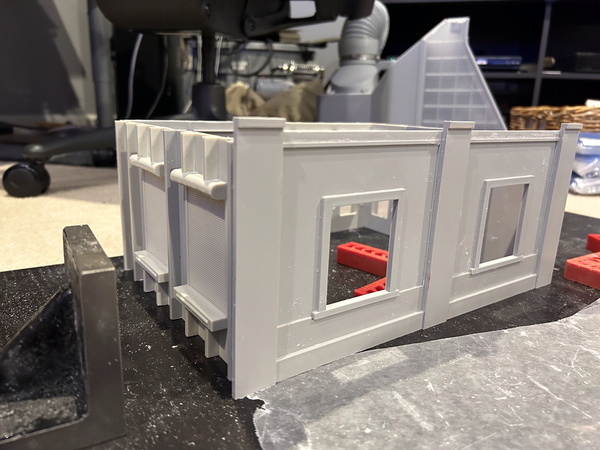

At this point, the building looked like this:

I thought.... hmmm that looks odd with the really tall side. It was at this point I looked at the directions again, and realized that the cornices were surplus. Even though I read the directions 12 times before starting, I was working on autopilot, having built a few MRS kits before, and too distracted by the hockey game on TV in the background to even think that using the supplied parts was in error (Disclaimer 3: if you plan to have the rail side face the edge of the layout, you could leave it like this, with an extended facade, but if the kit was packed right, you may not have these parts).

If you know how plastic solvent glue works, then you'll realize that doing the next step was NOT fun:

If your kit includes these parts, THROW THEM OUT.

After a lot of filing down the backs of the pilasters and the faces of the wall parts so they were smooth again, I re-glued the MRS wall back together (correctly, this time), and you end up with this, which makes much more sense:

The dock sections require similar trimming. Same thing... you can be short, just dont be long. If you come up short, then the top of the dock will overhang the base a tad, no biggie.

You need 5 sections to make the front of the dock. Trim about 1/2" out of the center section. I glued the 2 tops together, as well as 2 pairs of the front sections, then just trimmed the center section until it dropped into the gap, and glued it together (ruler for alignment).

8 dock sections are supplied but it only takes 7 to fill the perimeter. I glued the 8th section under the center seam of the dock.

8 dock sections are supplied but it only takes 7 to fill the perimeter. I glued the 8th section under the center seam of the dock.

Now you can see why I split the blank wall above, it moves the doors off the edge of the wall.

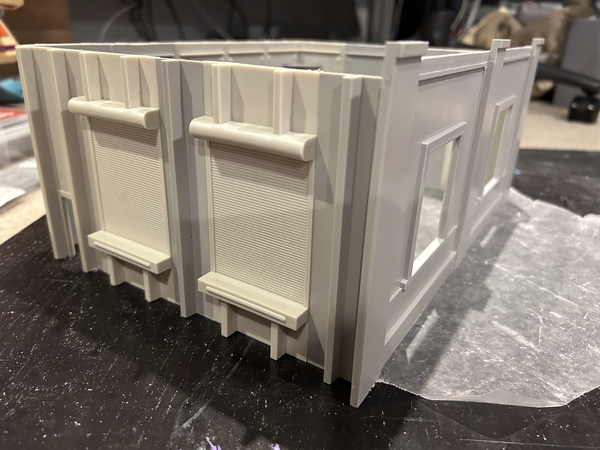

Check the windows and doors for proper fit, and adjust the fit as needed. Also take the time to dry fit the dock to the building, and file the profile where it meets the building as needed. The cutouts for the bottom plates of the doorways was a bit tight and some filing was needed. I did this before I washed everything in soap and water, and subsequently started painting parts Rustoleum Camo Khaki.

The braces you see in the corners are from City Classics.

This is how it currently stands. I'll paint the building tomorrow, I guess, then keep going. I plan on putting a shadowbox inside the rail dock doors, so I'm not planning on installing the doors. I might block off the office and put in a basic interior, depends how industrious I feel.

All in all, this is a neat kit and a clever use of modular parts. The combination of modular systems adds a little bit of interest to the building of it. There is no truly "precise" trimming needed, so dont be intimidated by the need to modify supplied parts. A zona saw, some sand paper and a file or 2 is all you need.

If you want to stretch the kit, then you would need to lengthen it in even numbers of MRS walls so you can use 5 full sections of TT on the opposing side. Otherwise you'll be cutting TT walls to match and, while doable, could lead to a little awkwardness with the position of the 'T's on the ends of the building. You could also add more MRS walls in a 3D fashion, stretching both the length and width, using the TT walls as a truck dock add on. The possibilities are quite limitless.

Will update this thread as progress continues. Might be slow or sporadic, as somewhere along the way, the layout is going to need a table extension and MOW needs to cut in a switch for a siding…