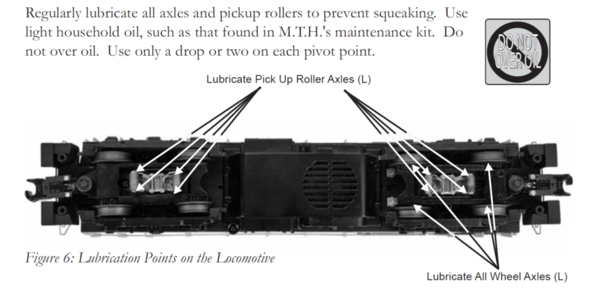

I picked up this beautiful SP&S RS-1 Alco Loco from my friends at Eastside Trains. This is my first MTH engine, I noticed in the instructions that they recommend oiling the pickup rollers. I thought it was unusual, so I though I would check with others on the forum regarding how long this has been recommended. The rollers look to have a rubber inner core. All the best, Dave

UPDATE: 1) I have added a picture of the rollers, so you can see it is metal and rubber; and 2) I have uploaded as an attachment the entire MTH Instructions Manual, which is 49 pages. It is very comprehensive, on page 33 is the section on Maintenance, including the steps on how to grease the worm gear and bronze drive gear.

Thanks for everyone's feedback!, Dave