I'd like to add some good info to this discussion, and yes I know this thread is now 2 years old. First, I'd like to acknowledge James Ingram, who posted above, much of what I've learned about MTH DCC is from him, his site, and his videos. However, as a long time NCE DCC user, I have some input on how to save a ton of money if you'd like to go DCC with MTH in O scale. First, I'm mostly a G scale person so I know about pulling a lot of Amps, DCC boosters, and the like. I've also done some research on the actual Amps that get pulled by G scale and O scale engines. Many people WAY over estimate what the engines actually pull. Example, I hear people say that the 4 motor Aristo-Craft Dash 9, one of the largest G scale engines, requires 5 Amp min. However, testing shows the actually max current, stall current is around 3.5 Amps. This was tested in Garden Railways Magazine. I have sucessfully run 2 G scale SD-45s on one 5 Amp / 24v DCC booster at fairly high speed steps before the booster hit its limit.

Ok, onto my tips. First, you can use ANY DCC system with O or G scale, you just need a booster along with the command station that has the right voltage and current specs. For O scale I recommend at least one 5 Amp booster at 16-18V. I use an NCE Powercab System, that I bought about 13 years ago for $125, they are now about $175. With that I've tried several boosters including a Bachmann 5A, two MRC 8A, and a custom MRC 8A booster that was modified to make two 6 Amp boosters (don't ask me how, someone else did it) and more recently the best bargain in the world.... Tam Valley Depot 5A boosters that cost only $50 or so, without a power supply. I'll get a photo below of my setup with the 5 Amp Tam Valley booster, I mounted everything on a board along with an NCE Mini-Panel for DCC train automation. My point is that you can have a fully functioning O scale DCC system for about $250-$270. I also have a 2nd NCE DCC ProCab as a 2nd throttle, and also use it as an easier way to program my NCE Mini-Panel. I buy many of my items used, my Procab was only $100 on eBay. As a matter of fact, I just purchased another NCE PowerCab system this week on eBay for only $130 with shipping! Now I'll have two completely separate DCC systems for O Scale and G scale, I've been switching back and forth these last few weeks.

Power supply selection. For G scale I can get 2 24v 6A power bricks on Amazon for only $23, yes TWO. I use one to power Tam Valley Depot Booster, with just under 24V to the track. For O scale this week I've been using an adjustable 5-24V 3A power supply (I'm about to purchase a 5 Amp model that goes for about $30 ) for testing etc. I can run 2 O scale engines with this, but it has cut out some since I reached 3A limit. I just have to reset everything when that happens, but no damage to the power brick. I set the power supply to just above 16V so I get about 16V AC to the Track from the booster. I spent much of the last several days testing 3 Railking MTH engines I just bought on eBay in DCC mode, all run GREAT with lots of nice options. I have a 4th engine on the way.

Like James Ingram, higher up in this thread, I build many Auto Control circuits in both Analog DC in G scale, and now working on DCC in G scale and O scale. BTW, I can also run Lionel Lionchief engines on the DCC track along with the DCC locos, I just use the lionchief remotes (or Lionel App) to run those independently. Today I was running both an MTH 2-8-0 steam engine on DCC and my Lionel Pacific 4-6-2 trains together on my small test layout. I then had 2 DCC engines running, and 1 lionchief and took turns putting one on the siding and running the other 2. As long as only a max of 2 were actually running at normal speed I never hit the limit of my 3 amp power supply. When I get the new 5 amp brick it will be great!

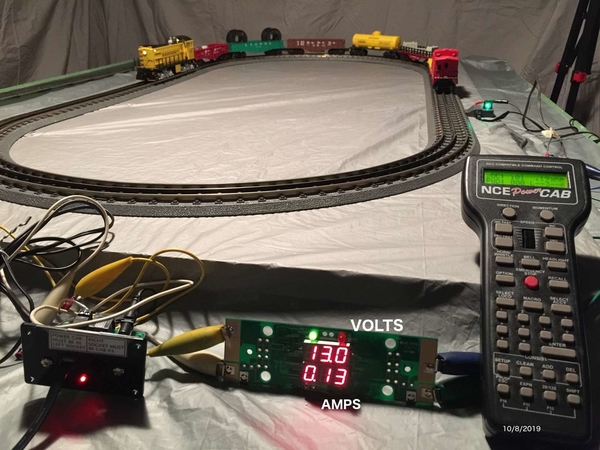

Below is a photo of my entire DCC setup. The Board is a 1x6 about 13 inches long. Top right is the Tam Valley Depot 5A DCC Booster, bottom right is the ProCab powered UTP panel, middle bottom is my NCE Mini-Panel used for automation (it's essentially a programmable NCE CAB unit with about 130 memory locations for code, and 30 inputs from detectors, reed switches, buttons or switches. The box on the left are connected to the Mini-Panel for starting automatic DCC sequences, plus switches for options in the code. This entire setup (with the extra Procab and Mini-Panel) is about a $400 investment, but for full featured DCC you don't need the Mini-panel or 2nd Cab. Also, for larger layouts just add additional boosters for each district. For most home layouts you should only need about 3 boosters/districts. Plus, you can get more powerful boosters if needed, but they will cost more. I'm in the process of building my own 10A booster based on an Arduino, I found the plans online.

Another Note: You don't need to use NCE. I've also built an Aurdino-based command station, with a Raspberry Pi 4 mini computer using JMRI software, with my phone and tablet as throttles. It's called DCC++ EX, you can find it on the web. Very inexpensive and works well, I just used my Booster to run my G scale trains with it. Heck, I used a base Bachamm DCC system I got for $100 back about 10 years ago with my MRC booster, and then Bachmann Booster to run G scale trains too. Just pick which system you like and you can get cheap. Right now, IMHO, one of the best out-of-the-box systems with 7 Amp booster built-in is the ESU 50210 CabControl Wireless DCC System with 7Amp booster variable voltage 15-21v. It is PERFECT for O scale DCC MTH based layout, and runs about $375 total. Let me know if you have any questions or need more info on anything.

Enjoy it as I will undoubtedly enjoy mine.

Enjoy it as I will undoubtedly enjoy mine.