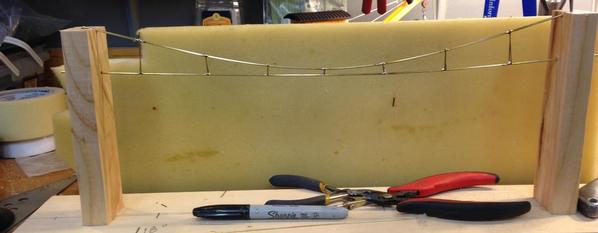

I've started building some catenary sections for my future empire. I'm using 1/16" and .032" brass rod. The distance between support posts is about 17" +/-. The 1/16" rod comes in 36" lengths, so one rod is enough for one complete section, suspension and contact wires.

The last layout that had catenary was about 30 years ago. I built that one in place using the 1/16" rod alone. It worked well but the carriers were a bit over sized. Plus, since I don't have a layout yet, building the catenary in place would be somewhat difficult.....LOL

In those days I soldered it all with a tiny gas torch. It was nothing more than a gas capsule, similar to CO2 capsules, housed in an open frame. There was a thumb screw on the top that punctured the tip of the capsule. I was alot younger then too. I have since upgraded to a butane refillable torch.

In that layout of long ago the catenary was live which allowed me more possibilities for running more trains on the same track.

Anyway, here are some photos of what I am doing. I built a jig to make the task a bit simpler. For some reason, the contact wire appears to be drooping. It has something to do with the photo, as it is actually straight.