At the suggestion of others here on the OGR Forum, I will commence with a time-to-time update on the progress of my new layout. It is located in a second-floor, climate controlled shared room. The size is 8'x16', Mianne benchwork and will be Hi-Rail. From learning here on the forum, I have decided to use Baltic Birch Ply over homasote (thanks GunRunner John!) as the base material.

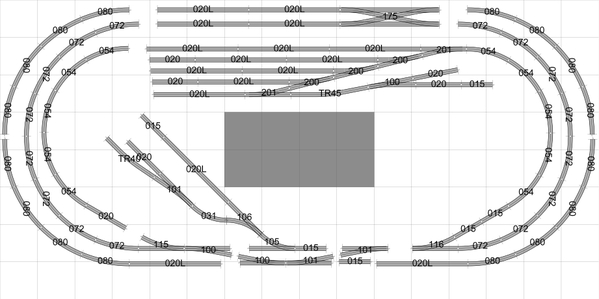

Track and switches will all be Ross over RossBed. From the experience of Putnam Division (thanks Peter!) I learned the best way to prepare the Rossbed. Base coat of grey primer, then followed by a topcoat of Rustoleum Stone grey for simulated ballast. All that material, except for the paint has been delivered. Still awaiting more primer and restocking of Stone grey for finishing. This will take time. Today I painted twelve more pieces of RossBed 14.5" straights using two methods learned here on another thread, and I have come up with the one I like best combining two styles into one.

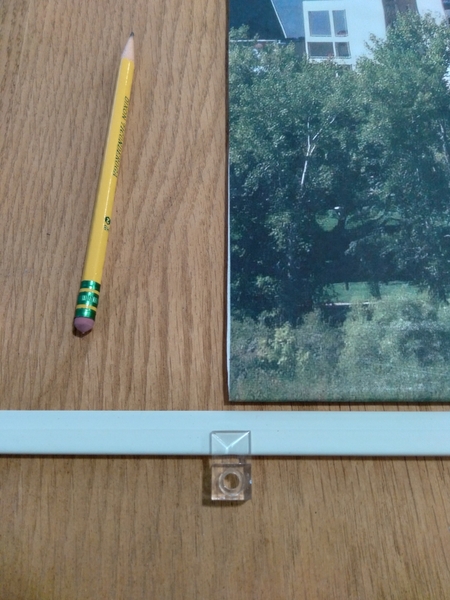

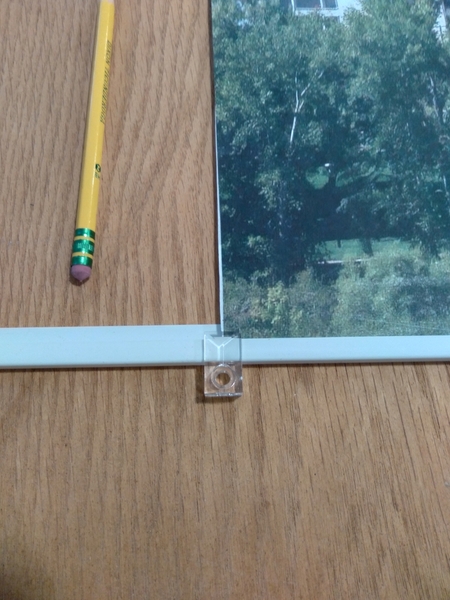

Here is the benchwork installed:

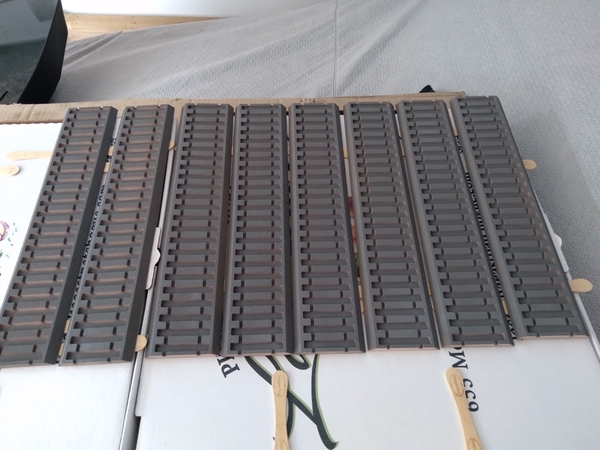

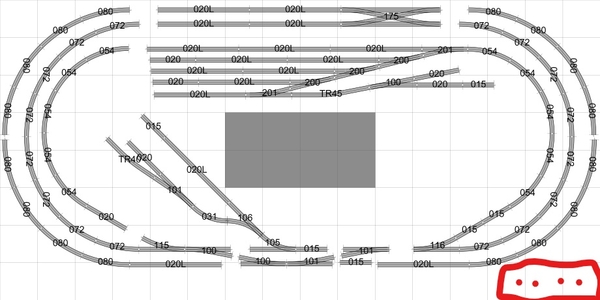

And here is the track plan, needs a brush-up to connect the loose ends: