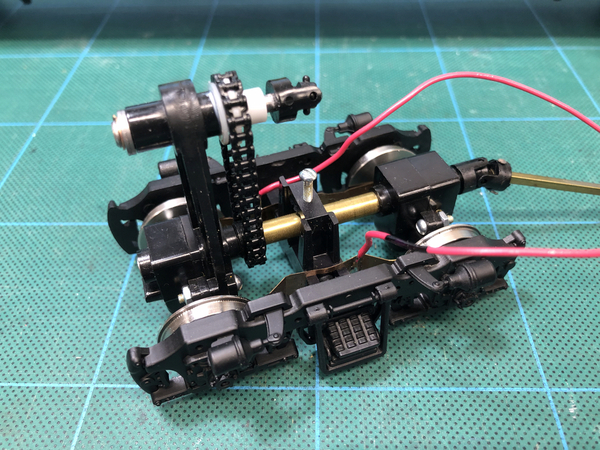

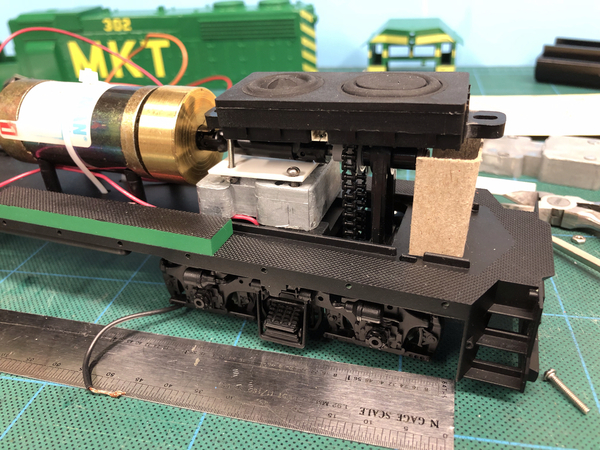

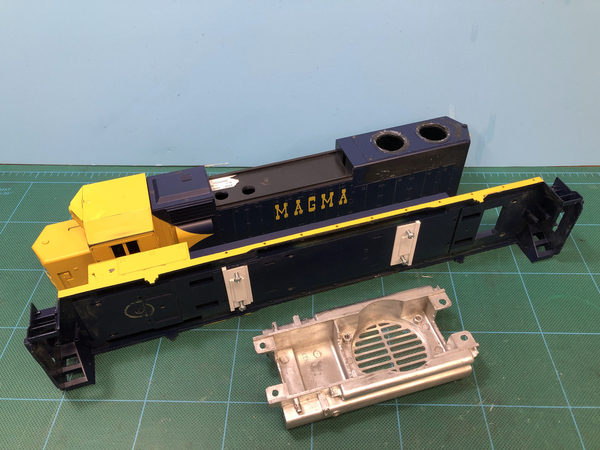

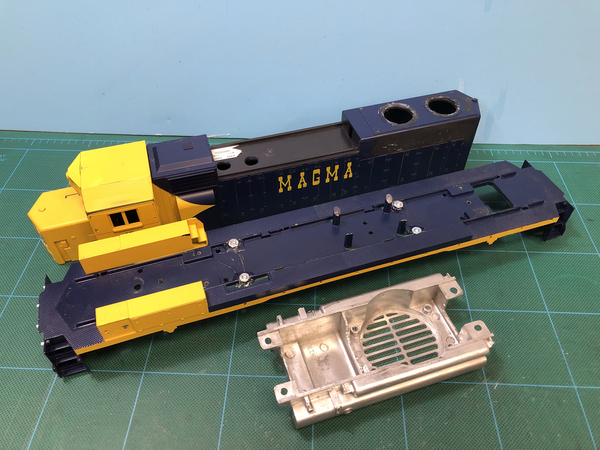

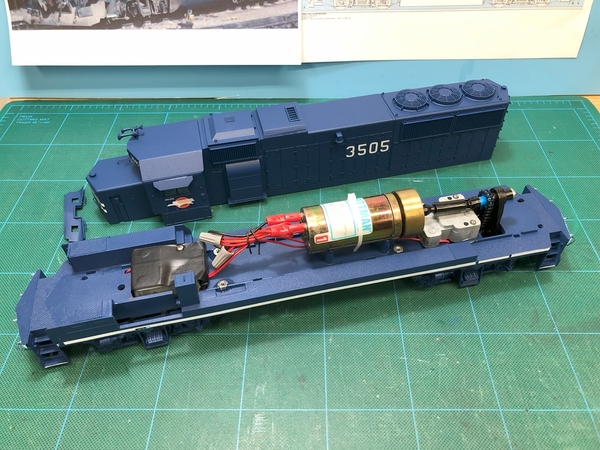

Hey Katy fans! Here's a Weaver GP38-2 project with some mods to better represent MKT 302, an early GP38. All pictures in this post are by me. The donor unit is a 3 rail Union Pacific model that was converted to 2 rail using NWSL 2504-6 geared axles. Converting to 2R was easy. After disassembly, I removed the 3 rail AC board and center rail pick-ups with the black wire leads. Two of the pick-up wires needed to be resoldered and I marked the leads of one side with black marker. I also removed the light bulbs and diodes from the motor leads as those will be controlled by a decoder. I think I spent more time removing the masking tape residue that Weaver used in place of electrical tape. Here's a pic of the 3 rail and new NWSL axles:

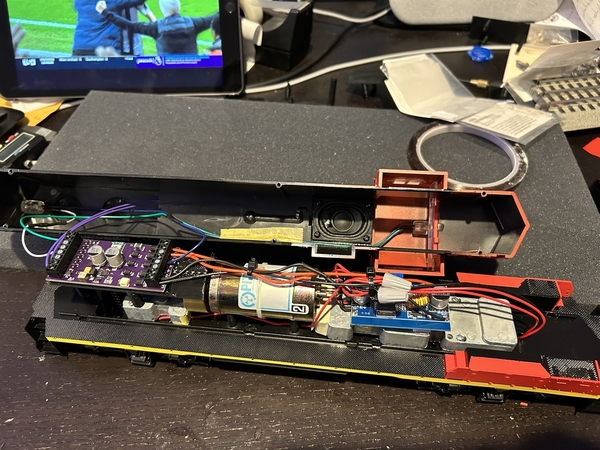

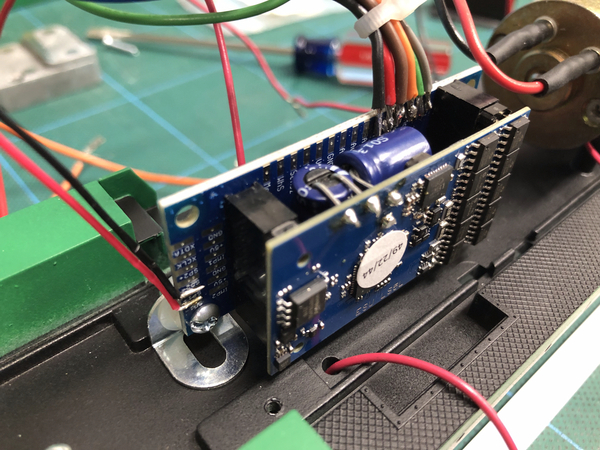

After replacing the axles, a quick test with a 9 volt battery revealed problems with the drive train. A broken upper sprocket gear was found and replaced on the tower drive with a new one from P&D Hobby. With basic DC running restored, a Loksound 5 L decoder loaded with a GP38 sound file and Tang Band 1925S speaker were temporarily wired in for testing on my office loop. I don't have DCC yet, however, the sound and basic DC features work well.

Stripping the paint - After several hours of soaking in 91% isopropyl alcohol with no progress, I decided to try Easy Off Heavy Duty oven cleaner in the yellow can. That worked great and didn't craze or damage any of the parts. By the way, I had a can of the Easy Off Fume Free oven cleaner in the blue can, so I tried that first with no luck.

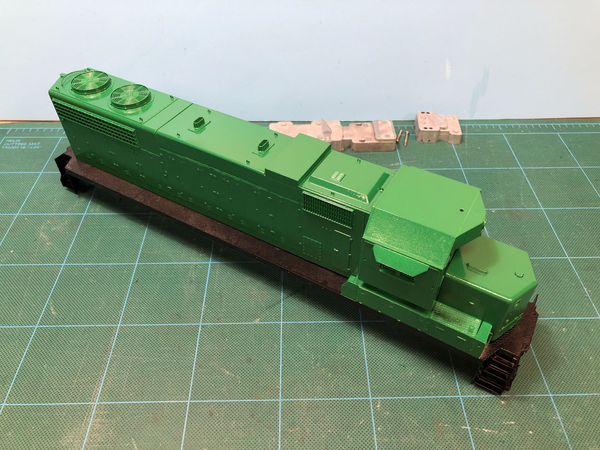

Based on prototype pics, I decided that John Deere green is a bit too yellow and went with this Rust-Oleum Gloss Meadow Green over a coat of Tamiya Fine White Primer:

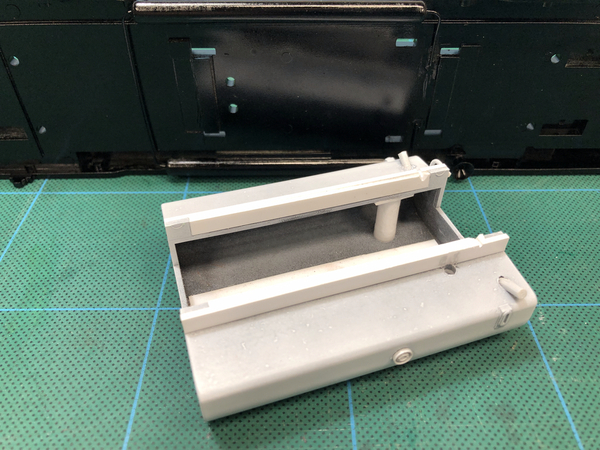

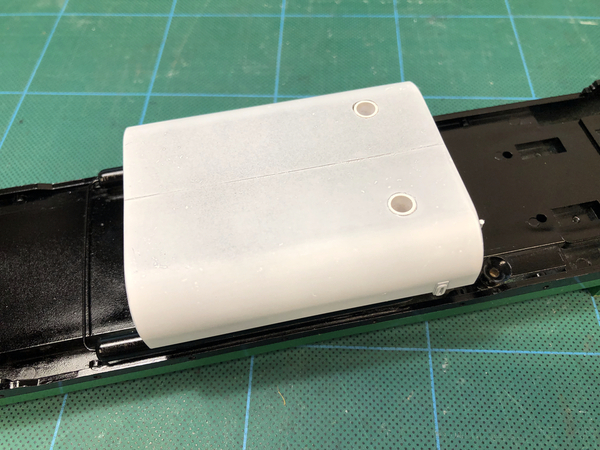

Shell modifications include shaving the molded grab irons and lift ring details and converting to non-dynamic brake. I also added a box to the right front walkway with a grab iron to match the prototype. I'll need to fix the gap shown in the photo below and touch up the battery box as my masking job wasn't as good as I thought:

Decals went on last night! If you look up "tedious" in the dictionary, one definition is "adding stripe decals to an MKT locomotive cab". I'll try to post those pics later today.

Happy modeling!

~Tim