John,

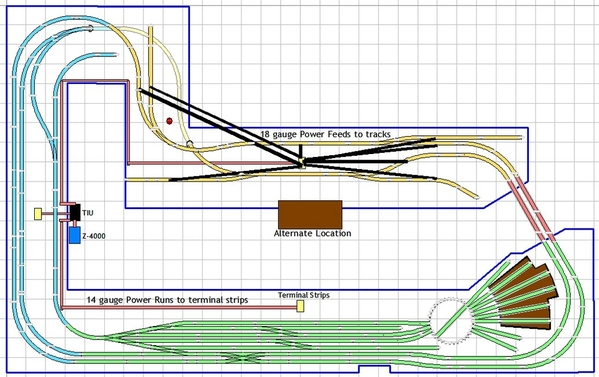

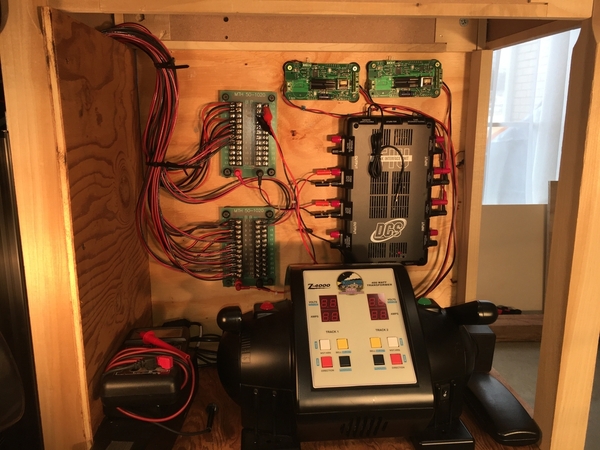

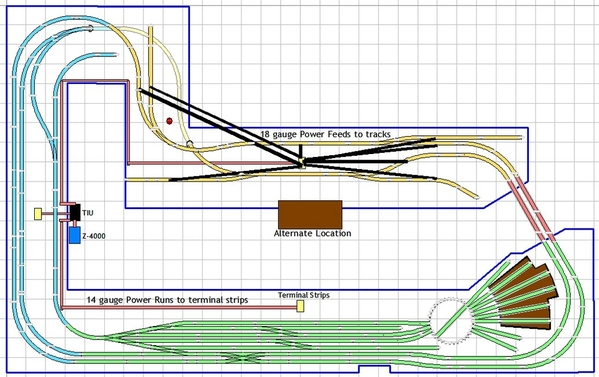

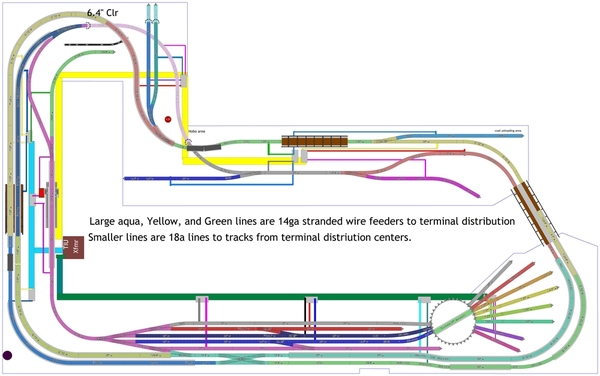

Here's a new photo. You can place the control panel with the Z-4000, TIU and AIUs pretty much anywhere. However, if you place it where the Brown rectangle is across from the yard AND you include the terminal strips like Mark did, you'll have to run a large number of power feeds all the way around the layout to get power to the yard. Looking at Marks photo, it appears he ran about 22 feeds and used larger gauge wires from the terminal strips to the tracks than from the TIU to the terminal strips.

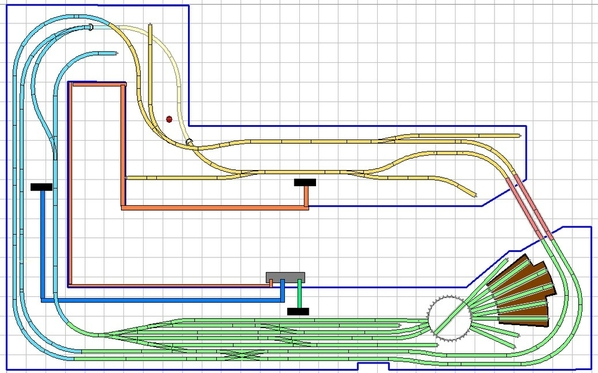

My suggestion is simply that you place your terminal strips closer to the track power blocks. If you leave the control panel where the Brown rectangle is, you need a single long feed to yard terminal strip, a medium length feed to the bridge terminal strip and a short feed to the town terminal strip. If you locate it where I have it though, you have a shorter run to the yard strip, a similar length run to the town strip and short run to the bridge strip. I don't the gauges wires Mark used, but if it matters, you'd use less of the larger gauge wire and more of the smaller gauge wire.

I added Red power feeds to the terminal strips and Black feeds to the tracks in the town. You'd have similar feeds from the other 2 terminal strips to the yard and bridge tracks.

I don't think either configuration is wrong, I just don't like having to trace long feeds when building or troubleshooting. Most wiring designs I've seen place terminal strips closer to the action, so to speak. If you unfold the design with the Green tracks on the left, the Blue in the middle and the Yellow on the right, you end up with all the terminal strips where the Brown rectangle is on one end of a long run.

Just food for thought, nothing more.