John, don't take this the wrong way, but you've given me headache.

I didn't get to look at the changes you made to the left side before I noticed this version doesn't include any of the changes I made to the version with 109a in the filename.

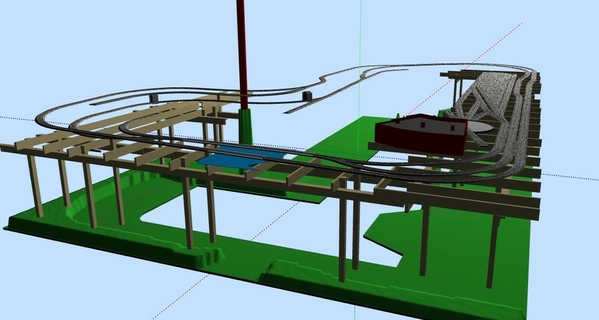

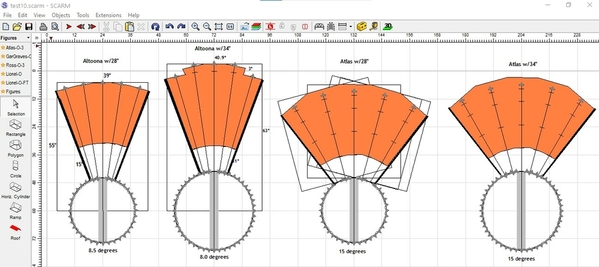

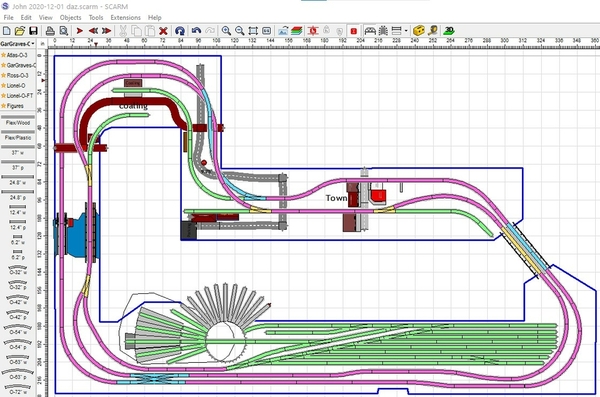

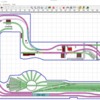

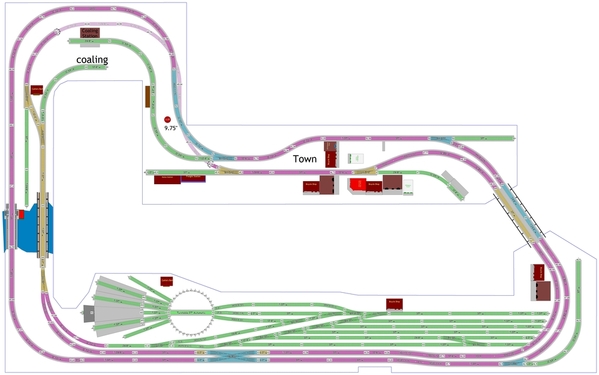

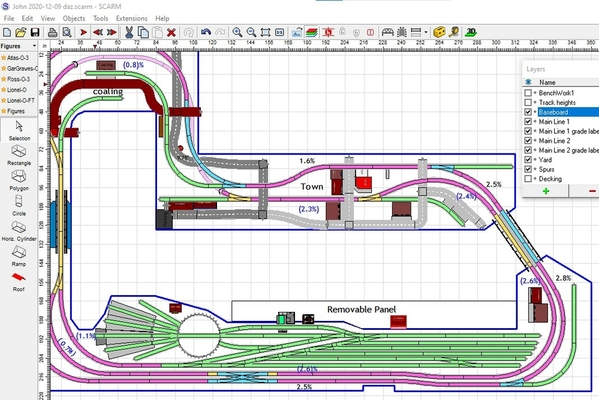

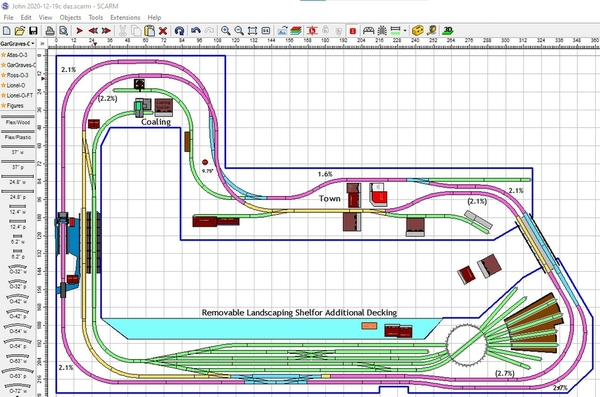

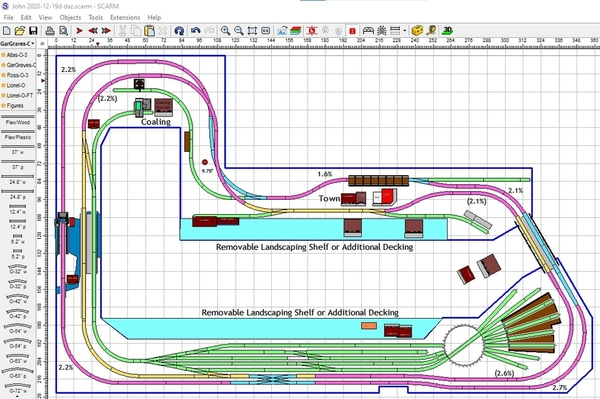

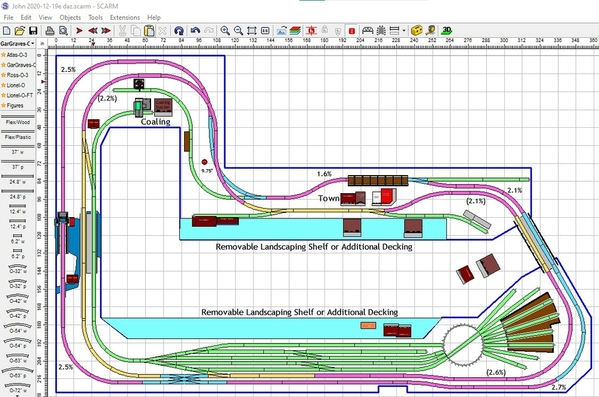

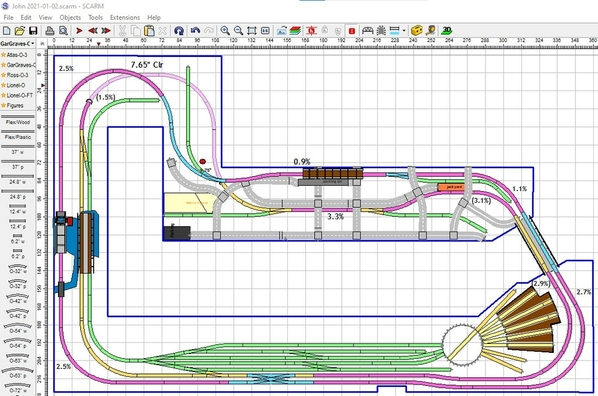

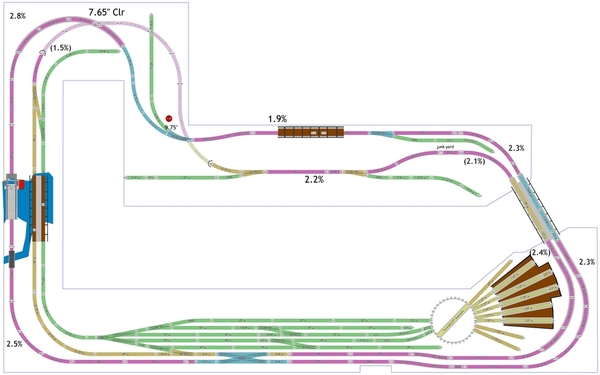

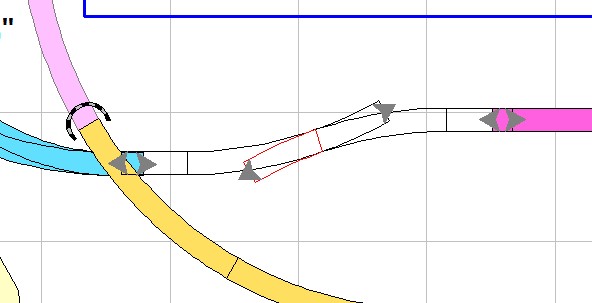

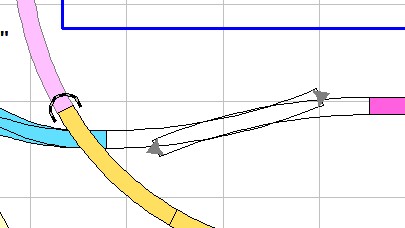

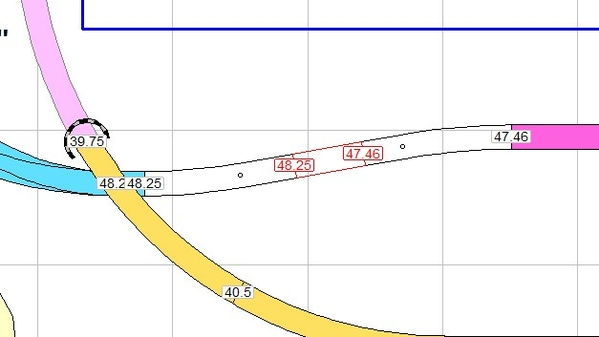

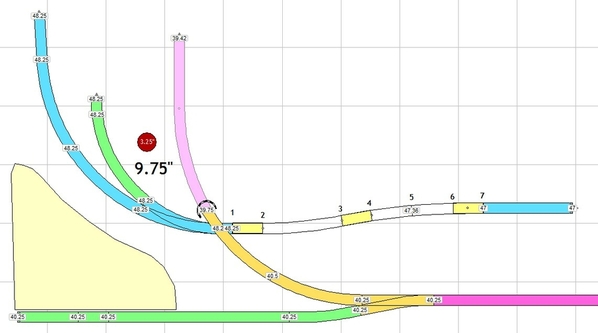

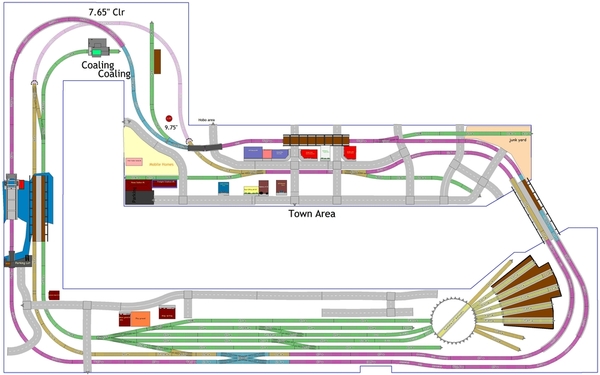

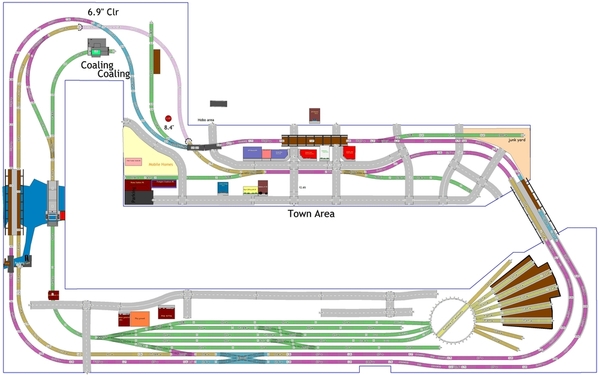

Anyway, I also noticed that the elevations from the mobile home park through town are all messed up. The curve from the blue switch to the bridge is back to not being smooth. The orange tunnel track under the overpass goes from 1.5" on one end to 2.25" on the other, a 3.9% grade. I believe this is an error in SCARM as a result of including the switch in the grade computation. If I just use the 2 orange tracks to go from 1.5" from the purple tracks to 2" at the switch, I get 1.75" and 1.3%.

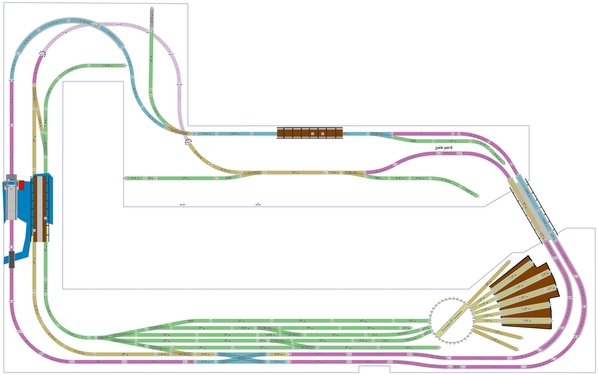

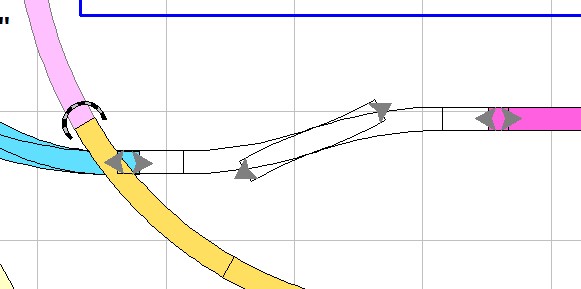

The tracks above that are now flat at 8.75" past the bridge. The switch on the right at 8.45" and the spur at 8.75" with a 1.2% grade for the first track. Unfortunately, with the switch at 8.45", the grade from the bridge to the switch is 2.0%, but after the switch to the next bridge is 3.0%. Now, if you put the switch on the grade, the lead is 8.38" while the exit and turnout are at 8.02" for a 2.5% grade. The first track of the spur then goes from 8.02" to 8.75" for a grade of 2.9%. This cab be adjusted because there is enough lead to the junk yard. The other thing is that a switch on a grade is probably frowned upon, possibly because the points may not to seat all the way and cause derailments. That's why I plan for switches to be flat and the grades to/from the switch be set to desired percentages.

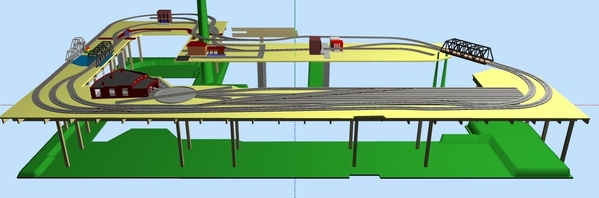

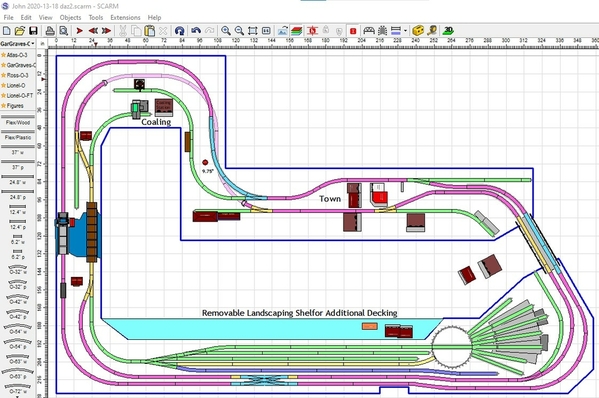

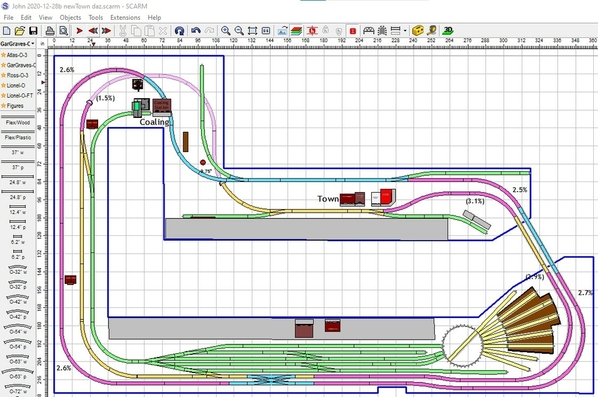

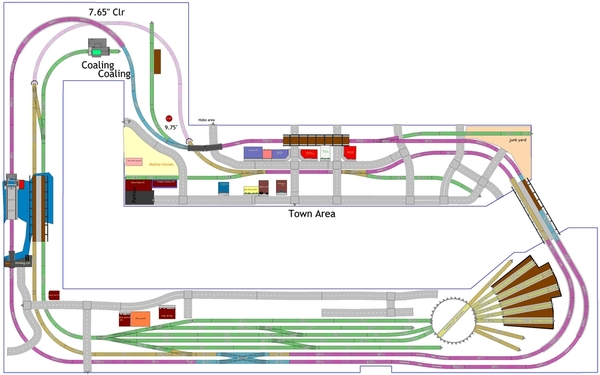

Okay, so when it comes to the major change you made on the left, now that you've made me think about that whole section, a Bascule bridge doesn't make any sense there at all. Bascule bridges aren't used at higher elevations, they're designed to let boat traffic through. With the static dual-track bridge there, there can't be any boat traffic to justify the Bascule. I could deal with it along the wall because there was room for cliff-style landscaping, but even that doesn't make any sense other than just for looks. It could make sense in the bridges were swapped, but you need the dual-track truss where it is. Sorry I didn't think of this earlier. I do like the addition of the mine track and the parking lot with pier. However, the lot and pier mean the track will need to be on elevated supports leading to the bridge, not on a hillside.

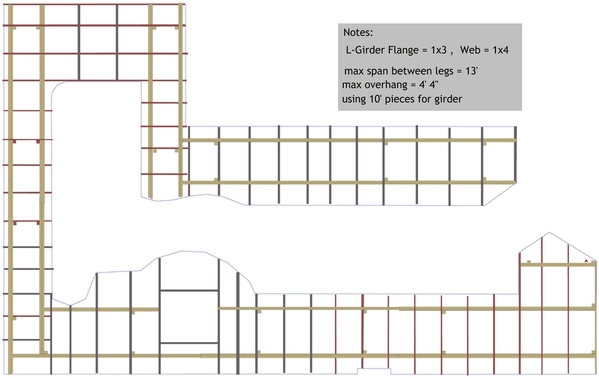

The other thing is that the changes aren't straight. This is because either the top curves aren't cut right or the bottom curve does not end perpendicular because of the flex track.

Now, I can fix everything, but you need to decide if you want to use the Bascule bridge strictly for display even though it's not close to prototypical. I also need you to look at my version 109a because that's the version I'll make the changes to. It's easier for me to make these new changes to it than fixe all the errors a 2nd time in this version.

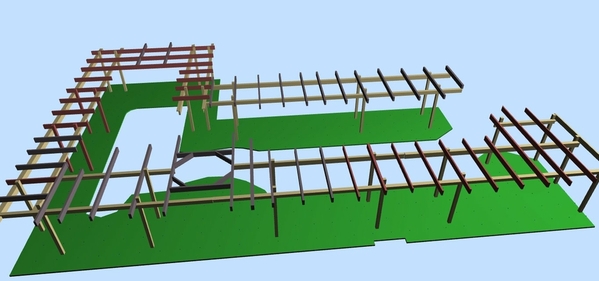

I did notice you lowered the track, bench work, etc., but you forgot about the furniture, utilities and walls. I'm not sure why those are still in the file unless you just want an overall view of the space.

So, let me know what you want me to do and if you've already made more changes before I've had a chance to consider these.

![]()