I was looking back thru the thread and realized a quick recap might be in order.

I also want to give a shout out and thank you to everyone on this thread and forum who offered advice and willingness to help sort out this unit’s problems - it is very much appreciated! Many kind offers were made to help me, but since I was already planning to attend O Scale West in February, I decided to take Jay Criswell up on his kind offer to take a look at it at the show - I took the body off the frame and packed it carefully in my camera bag and flew to California in February.

Jay spent at least 30 minutes with me at the show testing and tweaking the existing Kleinschmidt drive to no avail. He offered to take it home and make some suggestions - I readily agreed. Since he was going to be diving into this, I also made the decision to have it converted to Proto:48.

Jay made this conversion process very easy - I outlined my goals and he took it from there: I’m planning a switching layout so the engine should easily pull 8-10 brass cars up/down a maximum 2% grade with 54” curves, low speed behavior and smooth starts are critical, it needed sound and DCC, no concern about higher speeds as I don’t run fast passenger trains and make it run _perfectly_. After getting the engine back, he has accomplished all of them - haven’t tried the 8-10 cars yet as I only have a P:48 test track, but I have no doubt that this too will be fine.

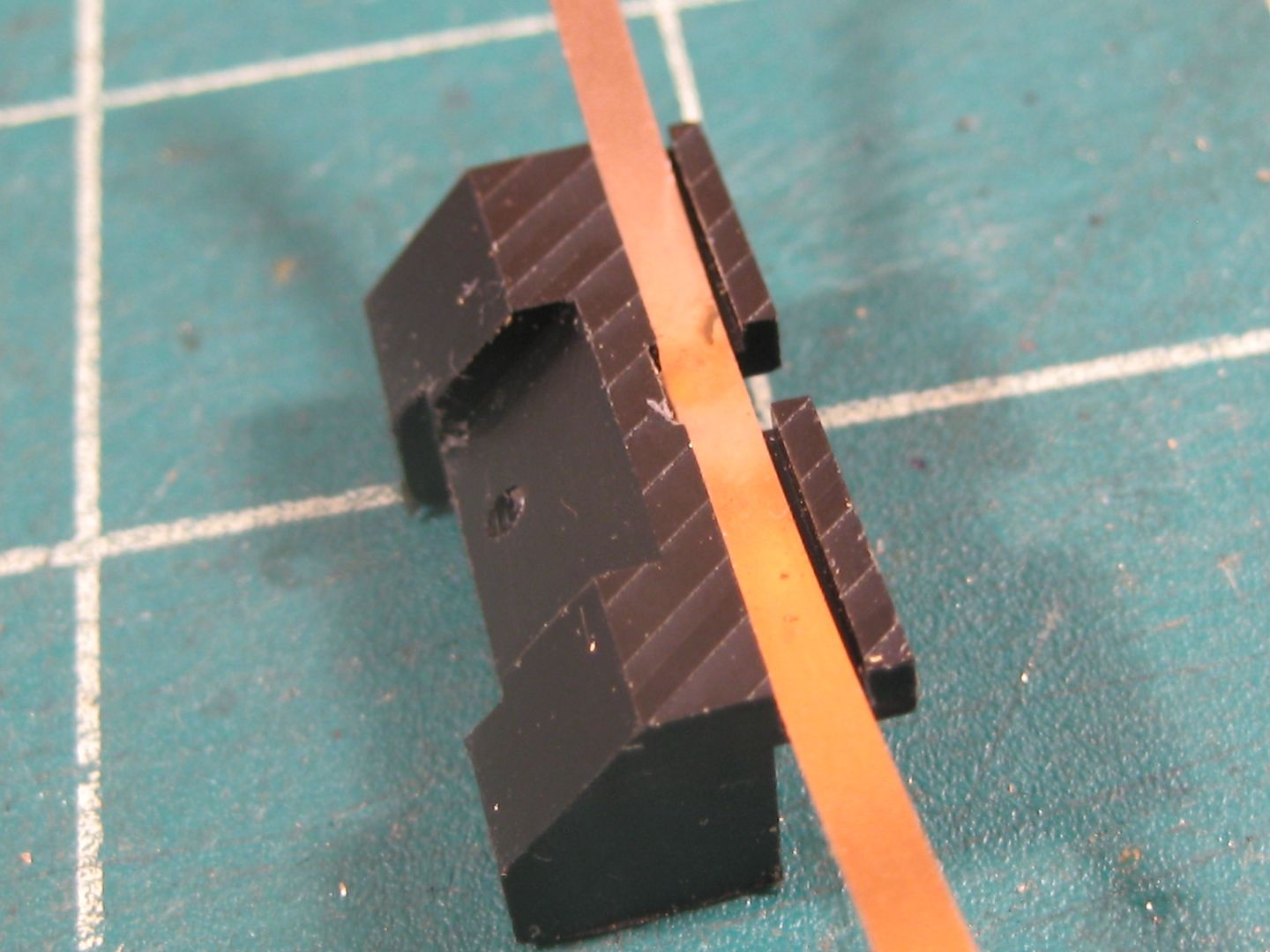

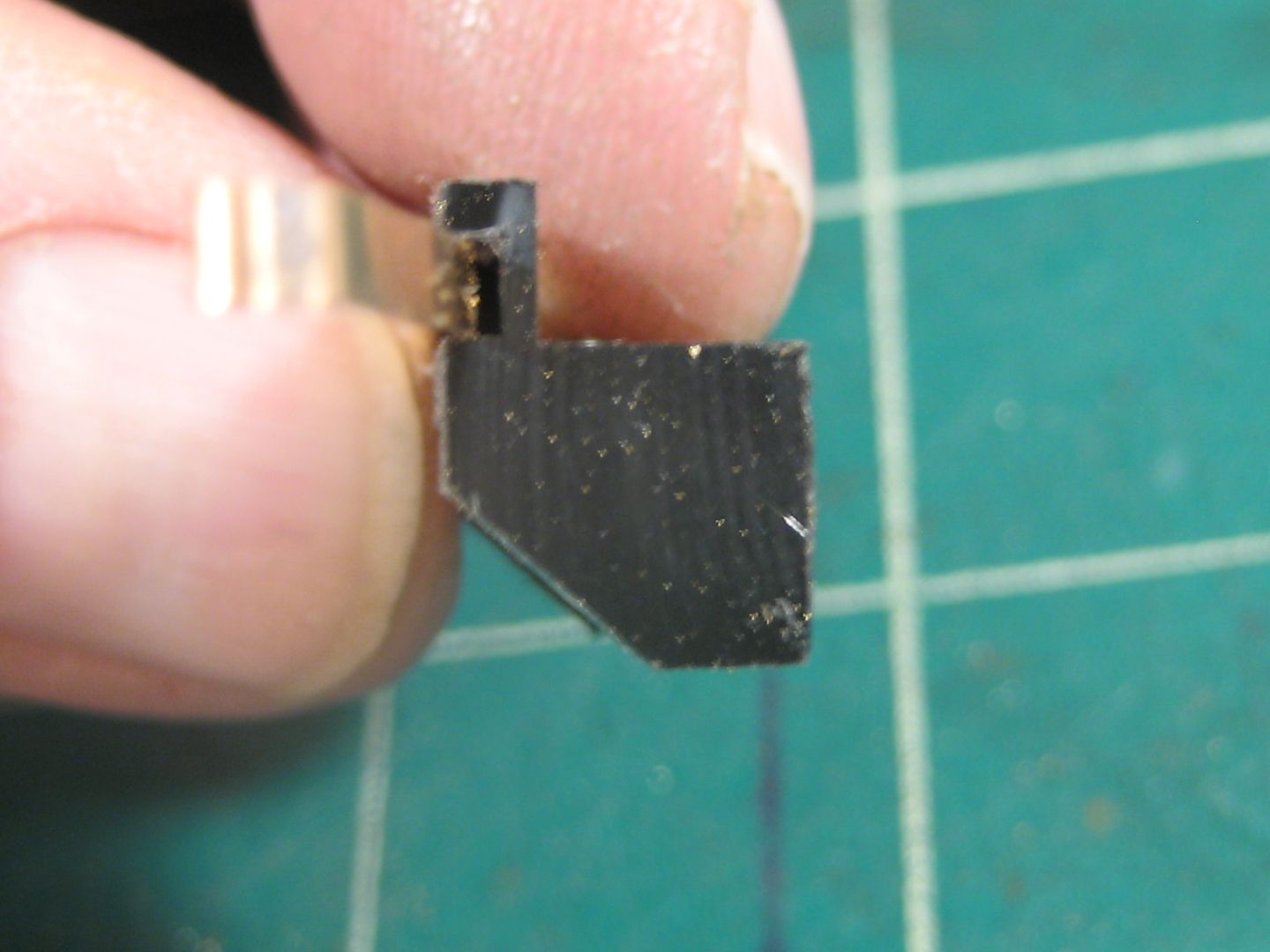

I had read concerns about custom work before - stories of months to get the job done. By the time I returned home from OSW, Jay had already begun and I had email waiting - he offered a variety of suggestions, some of which I had no clue about - a geared Swiss Faulhaber motor, Tsunami decoder, new wheelsets, etc. Via a series of detailed emails, we agreed on an approach and within 3 weeks, it was DONE - with complete photo documentation along the entire way (and even video). I have to say Jay made this whole process painless for this newbie venturing into 2R and P:48.

The engine arrived here yesterday, shortly after I picked up an NCE DCC system from my lLHS. Inside the well-protected package was the engine, the complete old Kleinschmidt drive completely intact with all of its screws and excess parts, Jay’s detailed handwritten notes and measurements, the decoder instructions, etc. I set up a test track and for the next 45 minutes, played with it watching it go back and forth about 8 feet. There is NO drivetrain noise, it takes off realistically and I can’t wait to tear up the 3R layout and get permanent P:48 track laid. (although my better half keeps talking about a new house - maybe not so fast

.)

Attached is a video of the engine - compare it to the first - no more noise, and jeez, that sound is phenomenal - I did not realize how nice the Tsumani sounds. And this is their regular unit - the motor pulls such little current, we were able to avoid having to use a high amp version.

Once I get the hang of DCC programming, I’ll wire up the LEDs and attach the body.

Jay deserves all of the credit for this magnificent job and a BIG THANK YOU - I look forward to working with him a lot more in the future. I’m now in the hunt for a 2-8-0 like this Missouri-Illinois unit.

...gregg