A lot has happened, but it still doesn't feel like much.

First off. I realized something about the new room: The floor is actually much more even than I originally thought. Like, almost dead even where I need it to be. After 2 months of fits and starts (and a 2 week trip to Scandinavia in the middle of it), I finally got the casters on every table leg. I ended up replacing the adjustable feet with casters and this has made my life so so so easy! I should've done this from the beginning

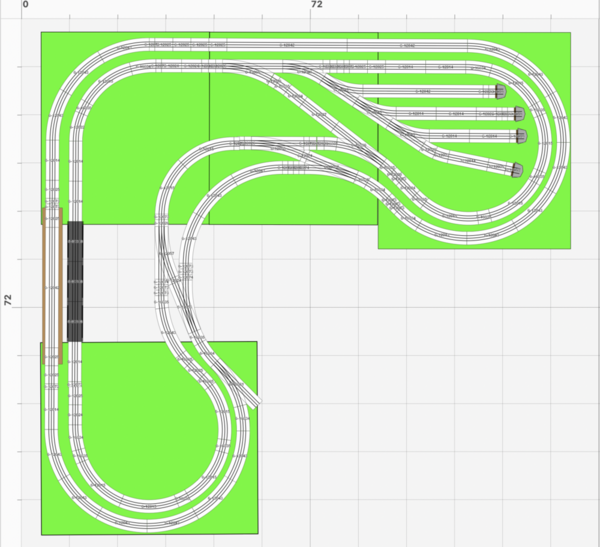

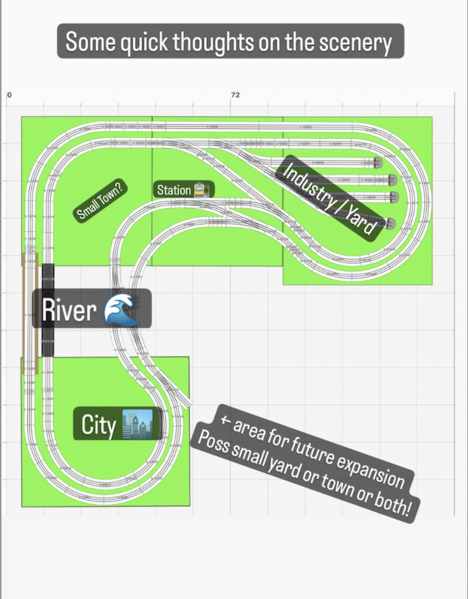

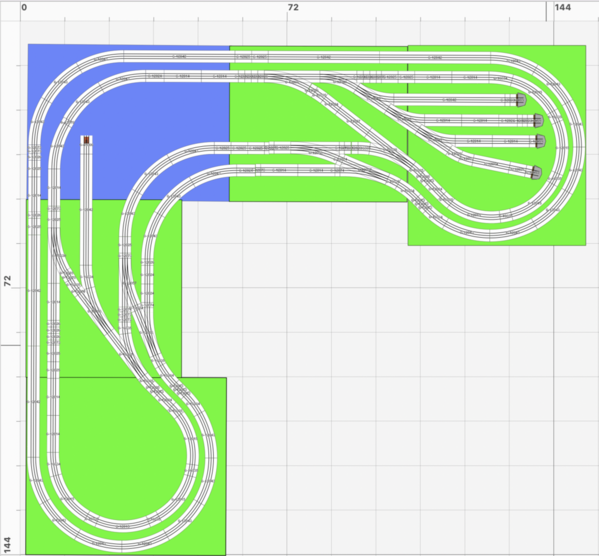

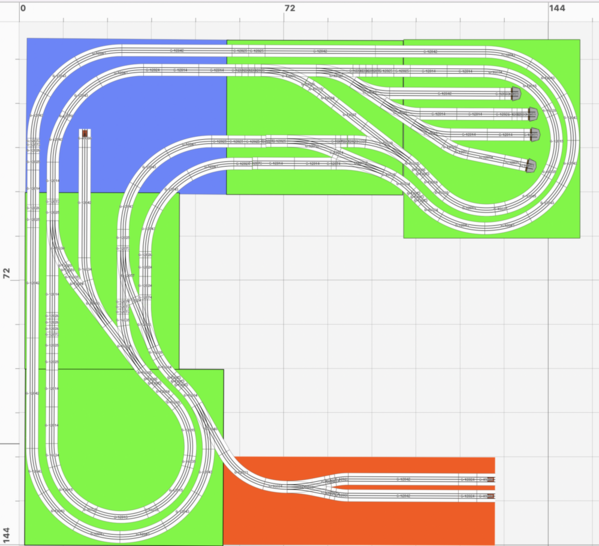

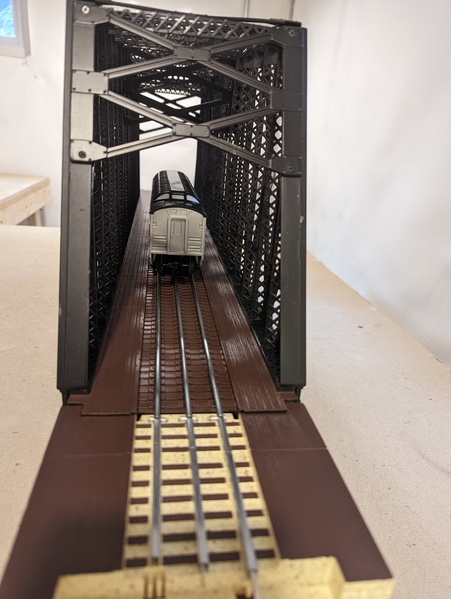

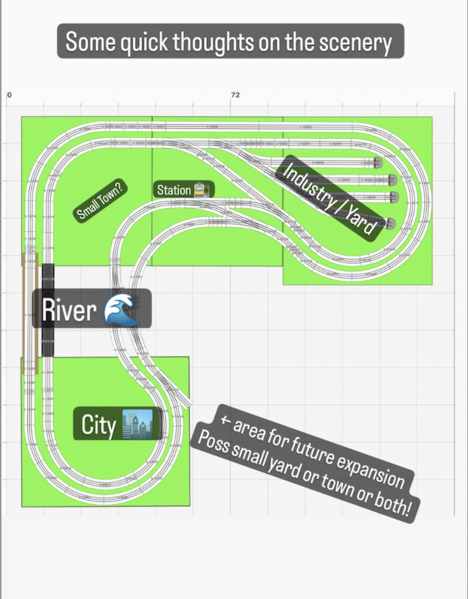

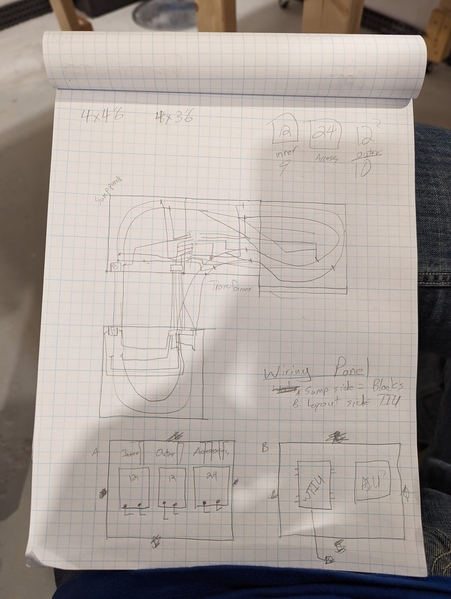

The second, and probably most detrimental thing is the layout design. After going back and forth, and getting a little overwhelmed by having to build more benchwork, my wife said "why don't you try to build something with what you have?" I was so hyper focused on a more detailed, larger plan, that I was missing out on the joy of actually running trains. So, with that, I scooted the modules around, and went to RailModeller, and....Voila! Version 5 of the layout. haha

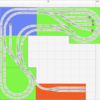

It uses all of the existing modules, but adds in the Fastrack Truss Bridge, 3 Fastrack girder bridges, and one I'll need to build one bridge. The new goal will be to add a river scenery module under the bridges there to make a pretty cool scene with some depth. Here are a few pictures of the new track plan, and what it looks like in the room. The best part, I've got enough room to get to the sump pump and can even roll the layout away from it if needed. Win, Win, Win!