Out of the blue it stopped running. When I power up it may move a few inches then stop. Here a clicking from the transformer (suspect a short somewhere). Took it apart. A short wire feel off from somewhere between the E-Unit, the smoke unit and the bulb. I think it was a poor soldering job I did about a year ago. Not sure if this wire has anything to do with the problem. Did a visual inspection of the E-Unit, did not take it off the motor. The wiring looks good, the fingers look good. Before I send it for repair does anyone have any clues? Thanks.

Replies sorted oldest to newest

The wires you speak of carry the AC hot power and is likely shorting against the boiler/frame which is grounded. Re soldering and securing the wire should take care if it.

bmoran4, I tend to agree. I just can't figure out which wire that might be, or where the loose wire came from. I think I need a "Post-War Steam Engine Wiring for Dummies" manual. How can I translate that great schematic to actual, real-life images I can work with? Thanks.

Why not share a picture (or few) of your locomotive and the broken wire and we can then help you line things up?

I just took a look at the engine (I disassembled it earlier). I cannot see a shorting issue anywhere. I do think I see where the fallen off wire to the smoke unit attaches the E-Unit.

Attachments

Thanks for the great pictures!

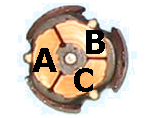

In the above annotated picture, the smoke unit wire should be soldered the same as the headlight and pickup wire in the red circle. However, this should not prevent the motor from operating.

In the orange circle is a former repair that may have failed. Also, the broken ring terminal may be the source of the short against the boiler.

But before we start making any more changes adjustments, the motor as pictured can be placed on track and operated (just be careful to keep the headlight out of any moving parts, and don't expect it to illuminate because it is not grounded by the boiler holding fixture). So, try the motor as is outside of the boiler and see if operation is any different or even normal.

Attachments

I did test the motor on the track. It runs about a second and then stops. It did the same fully assembled.

I suspected that the broken wire was the smoke unit and that the red circle is the soldering point. Thanks for clarifying that.

I have not opened the repair in the orange circle (I did the repair years back) so I am not sure if it failed. It feels sold when I manipulate it, but I may need to make a closer inspection.

I do not know, or see, the broken ring terminal that you are referring to.

Ring Terminal:

One was used in the repair in the orange circle posted earlier to mount the wire to the brush holder. It may be shorting against the boiler or the motor frame. This repair would have been of better quality having been done with 20 AWG solid copper wire so that the screw terminal could be utilized as intended, but then again, if it works well enough......

Next thing I would do would be to spray down the e-unit drum with contact cleaner like CRC 2-26 or Deoxit. Same for the center pickup rollers and see if that improves anything.

Attachments

bmoran4,

That connection has held up for a few years, but nothing lasts forever. I will rewire that connection with 20awg wire and directly terminate it. I will probably put some shrink tubing on it just as an extra precaution. Then I will spray CRC on those areas and see see what happens! Get back to you next week. Thanks for your advise.

BTW, while I have the engine exposed would you recommend that I replace the pellet smoke unit with a liquid unit?

Again, bmoran4, thanks for your advice and counsel.

If the original pellet type smoke unit is operating, no need to "upgrade" as I found the pellet type smoke units can use smoke fluid just fine as is without the need to worry about them burning out if ran dry like the "upgraded" liquid units. Even if you were to find your smoke unit to be faulty, I would rebuild it just like the original pellet type.

I do not often use the smoke unit, but I would like to start. It is kinda crusted / gummed over on the outside. Does it pay to sand that off or clean it in some other way? I can see the heat coils inside, so I guess that part is good.

I wouldn't use an abrasive to clean things up. I would think IPA with an old tooth brush would do the trick just fine. Obviously, make sure the IPA is fully evaporated off before applying any power.

Pardon my ignorance, what is an IPA? Not beer I assume![]() .

.

IPA = isopropyl alcohol

LoL, didn't know it by that abbreviation.![]()

@bmoran4 posted:IPA = isopropyl alcohol

99%? or would a lower percentage (70-91%) rubbing alcohol be ok for cleaning this smoke unit?

I currently have 99% on the workbench. I principally use it for cleaning flux off of circuit boards, but works on smoke units too!

Sadly, many of our vintage steamers have crumbling wiring. I agree on everything said so far... @bmoran4 seems to know his stuff and should be applauded. ![]()

Yes, I've had my share of crumbling wire over the years. Most of my engines are in the 80 year old range.

The #675 was one of the first locomotives I got when I went back into the hobby in the 1990's. When it's up and running please most a video.

Tom

Tom, I will post pix of it running next week - hopefully.![]()

The 675 is a nice loco and a good runner (when it is in running condition)!

I would check the brushes also. the one in back looks very short/worn. They may need to be replaced.

E unit troubles may also cause this. Is the drum still in place, sometimes the little ends that hold it in place break and the drum moves out of place.

The armature is fine. The unit made almost a complete oval around my track today b4 it died. Not the motor. Maybe a short as bmoran4 thinks it is. If not the next thing to check is the E-Unit.

bmoran4, happy Monday to you. I replaced the ring connector and attached a new wire. I put some electrical tape on the frame to insure no shorting. I made sure the wire was in no way near the frame. Same result. It moves a short distance and shorts out. No repostioning of the E-Unit makes a difference.

Does the transformer indicate a short somehow? Or does the locomotive just stop with no short indicator from the transformer?

Does another locomotive run over the same track with the same transformer?

Can you use alligator clips or similar to apply power directly to the frame and center rail pickup of the motor (in a makeshift cradle). Note the e-unit may be impacted by the different vector of gravity.

I may suggest also removing the brush plate to check the brushes and armature. You can ohm out the field coil and the commutator poles to check for opens, shorts, and proper resistance values.

There are many different types Lionel armatures differing in wire gauge, length, turns, and a healthy resistance measuring between roughly 1 and 3.0 ohms.

Set your multimeter to ohms and then test each combination of the 3 commutator faces. The reading should be essentially the same (and somewhere between 1.0 and 3.0 ohms).

In other words, the measurements of A to B, A to C and B to C should all be about the same and within spec.

Then test A to Shaft, B to Shaft, and C to Shaft. All of those should be essentially infinite Ohms (no continuity).

This procedure can be used on most any Lionel armature, however, the specific expected ohm reading varies from model to model.

You can also wire the motor to bypass the e-unit for testing like this:

Additionally, if this falls beyond your comfort zone, we both are in NYS, just on opposite sides, but if interested, I can refresh/rebuild/service/whatever your motor needs if you cover parts and shipping. Email is in my profile.

I would be happy to send the unit to you and foot the parts and shipping costs. I could not find your profile however. You can email or message me confidentially if you like.

What you describe could be dirty e unit drum and fingers; Just a an idea that works for me when I believe I have a shaky e unit; I spray the drum and fingers with a squirt of WD40; than I blow out the residue; the WD washes out dirty residue on the fingers and drum and helps with the contact surfaces; good luck. Falcon70

@Falcon70 posted:I spray the drum and fingers with a squirt of WD40; than I blow out the residue; the WD washes out dirty residue on the fingers and drum and helps with the contact surfaces

The aforementioned CRC 2-26 or Deoxit is a much better choice for cleaning electrical surfaces

@bmoran4 posted:spray down the e-unit drum with contact cleaner like CRC 2-26 or Deoxit. Same for the center pickup rollers and see if that improves anything.

Nope

@Dennis Rosenthal posted:I would be happy to send the unit to you and foot the parts and shipping costs. I could not find your profile however. You can email or message me confidentially if you like.

I got your email and responded. Glad to help you out!

Sorry just saw this thread and first thing i noticed in picture the last pic at the back of e-unit< non lever side> there is a wire between motor and e-unit that may need looking at to see if the insulation is broke along its path.

In the end it is most likely a fault within the e-unit itself as that is a weak area for postwar steam engines i have found out .

The 675 and 2025 with the baldwin tires run great along with being pretty quiet for a spur gear motor and very smooth least that has been my experience.

Please let us know what was found faulty as somewhere down the line it may help another .

bmoran4, did some work on the motor and sent it back to me. I had a chance to put the whole thing together again today. It runs better than it ever did. Great work Brian!

Can you explain what was wrong with the motor/wiring or was there another issue? It would great to know what got your engine back running again.

Jeff

@JWF, Principal issue was the armature which didn't ohm out appropriately. Replaced that along with new brushes and brush springs and now we have a fantastic runner! Replacing the armature required pulling a wheel, so it was good to send it off where appropriate tools and experience was had to ensure it would go back together quartered correctly.

Yes, we do. I put it all back together. Your work was like a fountain of youth for this steamer. Thanks again.

Thanks for the update, the 675 is my favorite steamer.