My elderly friend Ed (now deceased) did this sort of work in his train repair and restoration workshop. He had a compact bead blaster unit from Harbor Freight which was relatively inexpensive, but it takes a fairly big air compressor to run it, and some work space for the equipment.

Bead blasting is not difficult to do for a mechanical person who knows how to do other train repair work for themselves. I used his machine to clean up some old rusty track and train parts. You have to learn some technique of using just the right amount of blasting to clean off paint etc without eroding the metal too much. The technique is somewhat similar to using a high-pressure sprayer to wash a deck: you need to keep the spray pattern moving steadily across the work surface to avoid gouging the wood.

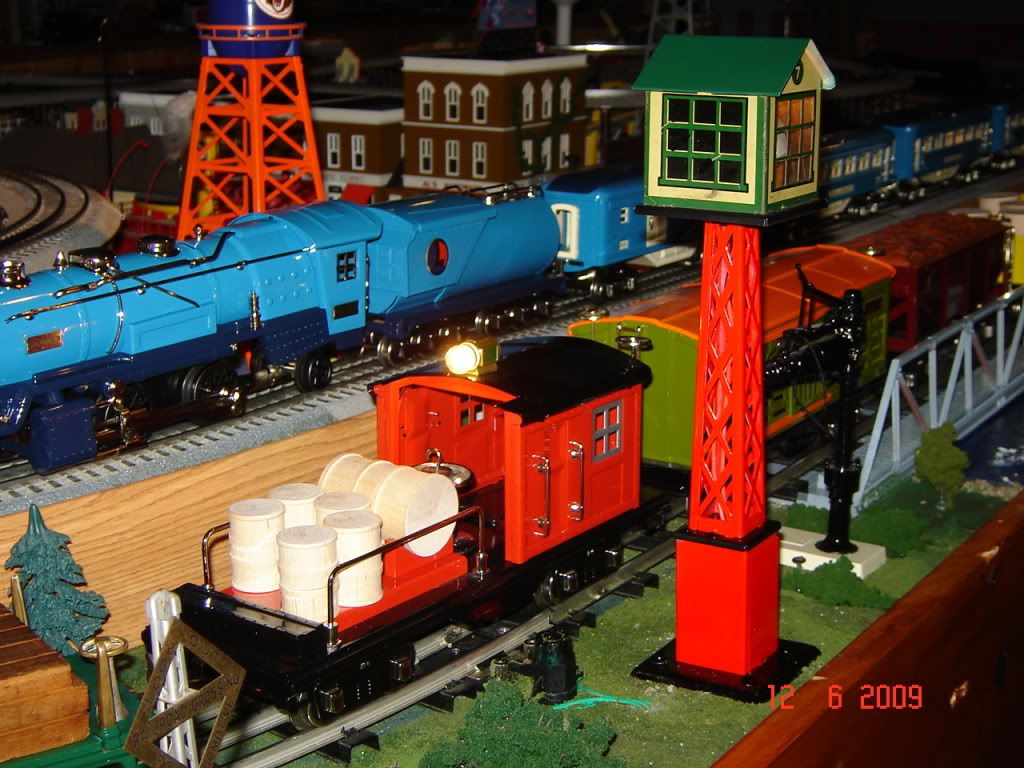

Bead blasting leaves the metal with a uniformly smooth finish and some "tooth" that helps paint adherence. Ed did all his painting with spray cans, with good results - at least as good as Lionel did 80-90 years ago.

Ed's bead blaster had heavy use and eventually needed some parts replaced. It tended to leak sand in his indoor workshop area so he moved it to a sheltered carport area outside and adjacent to the workshop.

Anyhow, my point is that anyone with some mechanical repair competence can do bead-blasting themselves with readily available equipment. It's not rocket science. It requires a large air compressor and some workshop space. If a person intends to do much restoration work on metal train parts, they may want to consider getting the equipment for themselves. It's satisfying work to be able to do all phases of restoration work, and convenient to have your own facilities.