What would be a general purpose SPDT relay for our hobby? I know there are different relays for different purposes, but what would be the specifics on a relay that would work in our 18v miniature world for say sidings that would need to keep the 18v.

Replies sorted oldest to newest

I like these from Automation Direct - I can't get the link to work correctly. From their main page go to - Relays / Timers > Electro-Mechanical Relays > Square / Cube Relays... > General Purpose, 15A (781, 782, 783, 784 series)

Or from the link above search for: General Purpose, 15A (781 / 782 / 783 / 784 Series)

They have lights for energized, push to test button and are 15 amp rated. They also have very nice sockets available for them. You can get them in 1, 2, 3 and 4 pole double throw. And available in 12VAC and 12VDC. Reasonably priced for what you get, at least I think so.

I usually get the 12VAC and use them with an accessory output or transformer at 12-14VAC. The 24VAC ones might work with 18VAC? I have not tried this. I don't know if any relays in 18VAC are made?

Just looked at the specs, these would not work with 18 volts. They require 85% of rated voltage to energize the coil, so probably near 21 volts to be safe.

I have installed a 24 VAC relay on one of the Fort Pitt High Railer modules. Works best with a full 18 volts plus, may be even 20 volts if you can get it from a toy train transformer. Less than 18 volts, it won't work.

Grainger Supply Relay 24 VAC Also available in 12 VAC

I have installed a 24 VAC relay on one of the Fort Pitt High Railer modules. Works best with a full 18 volts plus, may be even 20 volts if you can get it from a toy train transformer. Less than 18 volts, it won't work.

Kind of what I was thinking, thought it might be more like 20-21 volts to operate them reliably. I would imagine even if the 18 volts worked with these it may cause chattering in certain applications?

I've used the 12v SPDT relays commonly found in Radioshack stores with great success over the years.

-John

Yes, that is one of the relays (or the page of them). If you select a relay and scroll down the page a bit the sockets will be listed.

Your link did the same as mine, I had to use the search box to get to it. For some reason this site's pages won't link properly?

See my post above again also, I edited it earlier. The 24 VAC relays don't look like they will work on 18 volts. I looked at the specs.

Looks like they are still offering free 2 day shipping on orders over $49 as well. They have had that for a couple of years at least.

I believe our newest Forum Sponsor, Train Electrics, sells 12 VAC relays designed for our typical O gauge applications.

Bill

For signaling and the like, I prefer DC relays as I want a capacitor to prevent contact chatter.

I have had good luck with Radio Shack Relays

http://www.radioshack.com/12vd...2750218.html#start=4

I have used them for my block signals - you need a bridge rectifier to go from AC to DC and as gunrunnerjohn said adding a Capacitor to prevent chatter. Here is my basic set up for using a relay for a Lionel Block Signal.

Steve

For signaling and the like, I prefer DC relays as I want a capacitor to prevent contact chatter.

So you are using a DC power source to run the relay but running ac to control the signal?

I suggest a small resistor to limit inrush current and arcing when the initial charge of the capacitor occurs as the wheels make the connection.

Yes, you can use either AC or DC on the contacts, that has no connection to the relay coil actuation.

See my post above - AC track current is converted to DC by the bridge rectifier then DC current goes into the relay. The wheels on your train cars are acting as a switch closing the circuit to the relay. If you have dirty wheels on your train cars the connection from the control rail might be interrupted which can result in causing the relay coil to chatter. The capacitor holds come of the current to keep the relay closed. As far as the power to the signal lamps you can use what ever you need for the type of signal you are using. Good old Lionel signals work well on AC - but DC power can also be used. If you have signals that use LEDs then you need DC to power your signal

Steve

As I see it, the O-gauge model train market is a speck of dust compared to the automotive and other markets. The availability, cost, etc. of 12V DC relays and associated 12V DC widgets useful for model trains such as time-delay modules makes it the way to go.

In the last couple years, the flood-gates have opened on attractively priced 12V DC relay modules from Asia. At about $1-2 per channel on eBay (shipping included), they're a great value. Picture shows a 1-channel and 8-channel module but 2, 4, and 16 channel modules are also readily available. Many/most have screw-terminals and/or connector to simplify hookup which reduces soldering. To deal with relay chattering, buzzing, inrush current and so on you generally need to fuss with adding discrete parts (diodes, bridge rectifiers, capacitors, resistors) often requiring basic soldering.

But the real "win" with these modules is if you use an isolated 12V DC power supply to power the modules. It can be an isolated 12V DC wall-wart (a few bucks), a spare transformer with an AC-to-DC regulator module (a few bucks), etc.. The idea is the modules are always powered with 12V DC and the control current to turn one on is very small since you don't actually "switch" the relay coil current across the isolated-rail; the modules have on-board transistors to drive the relay coils. Many good things happen when you don't have to switch the full relay coil current across the isolated-rails - more details if you're interested.

Attachments

I would also recommend following steve24944, gunrunnerjohn and stan2004's advice. I had forgotten about the relays that stan2004 has posted, a much better value and DC to boot. (I actually even have some of these around here somewhere)

Also, the Radio Shack relays are a lot cheaper than I thought, I was thinking they were like $10-$12 or so? Don't know where I got that now, maybe from their in store stock? Another great thing about this forum is all the neat stuff you find from other members posting's about the things they are using, many with details on how they do it too.

I forgot the modules Stan mentions, and I also have a few different examples. The basic relay works well too, and the coil current for many isn't all that significant.

But if you have a DZ1000 controlling the relay then it needs to be an AC relay. ( without creating a AC to Dc conversion project)

But if you have a DZ1000 controlling the relay then it needs to be an AC relay. ( without creating a AC to Dc conversion project) Or can a DZ1000 be run on DC?

But if you have a DZ1000 controlling the relay then it needs to be an AC relay. ( without creating a AC to Dc conversion project)

Why?

For a crossover or a double slip changing to polarity to + / -.

For a crossover or a double slip changing to polarity to + / -.

Well this conversation has gotten way over my reading comprehesion level ![]()

My point was the faster/sooner you can convert and operate in the DC world the better off you are. Modern engines long ago converted from AC motors to DC can motors. The first thing our command controllers do is convert from AC to DC to do their magic. Even our lighting is converting from AC (incandescent) bulbs to DC LEDs. And while you can still buy AC relays, DC relays are more available, economical, etc.. The cost or "penalty" of the legacy of AC track voltage in O-gauge is fussing with the conversion from AC to DC which in practical terms means messing with diodes, bridge rectifiers, capacitors, etc.. In my opinion of course.

I also think DZ1000's are AC? I am not sure if a DZ1000 will work on DC? However, some items will work with AC or DC that are stated to require AC. Others have reported using DC to operate Atlas switch machines (what I have) and obtained better performance with them. I have not tried this, but plan to try it someday, I have some old, weak switch machines left over after installing a some new ones in their place. Good sacrificial items for experimentation. ![]()

After the advice about the DC relay, I remembered once using an AC relay for a signal crossing. Energizing it with an isolated rail. It did chatter slightly when the train entered the isolated block and first pulled in the relay. After that, it stayed pulled in until the train left the block, there was no chatter and all was well until time to energize it again.

If you are energizing the relay directly with the DZ1000 then an AC relay might work for you? I have never tried this. I am not understanding what you are trying to do or how you want to do it?

I think our MTR-12T relay would do the job for you - personal opinion.

- Ac or DC input

- Anti chatter

- Spike suppressed

- 15 amp contacts

- LED actuation indicator

- DIN rail mounted

- Screw posts

- Made in the USA

No muss- no fuss, it's all there in one package and easy to hook up.

Neil

Then what can I do with a bunch of DC relays RH2-ULC 12VDC from IDEC? Thinking about this more, Could use DC as control voltage of the relay and let the relay switch the switch in AC and switch the polarity for a Ross Double slip?

Then what can I do with a bunch of DC relays RH2-ULC 12VDC from IDEC?

Get a bridge rectifier and a capacitor for each relay. Set up some insulated control rails and get some block signals. Lionel 151 semaphores or 153 Block Signal. Or if you want to be more to scale there are a lot of scale signals out there

NJ International http://www.njinternational.com/oscale.htm

Custom Signals http://www.customsignals.com/signals.php

Or you can scratch build your own signals.

The relays can also be used for crossing gates.

Steve

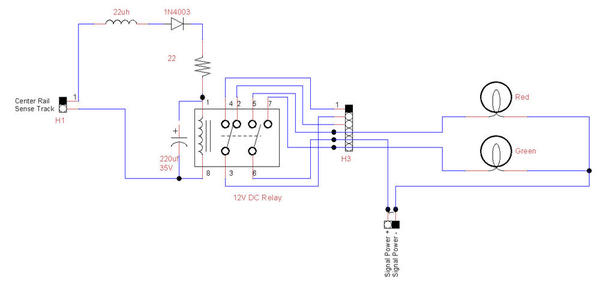

Here's a simple circuit I put together to do signals. The relay is a 12V coil salvaged from old control boards. It has a choke to minimize any DCS signal interference, the resistor to minimize any inrush charging current so you don't have arcing, and the capacitor to eliminate chatter during the initial activation. You can do it for peanuts, 12V DC relays are a dime a dozen. If you have 24V DC relays, I substitute a bridge rectifier for the diode, so far that has never failed me.

This illustrates driving bulbs on both open and closed, it was drawn for driving signals. Obviously, the relay contact configuration can be anything your application requires, the ones that I salvaged happened to be DPDT relays.

Attachments

The companies I worked for over the years used Idec relays almost exclusively, they are good relays.

GRJ, drawing saved and added to the project list, I can adapt this to my crossing gates and eliminate relay chatter this time around. Thank you again. We need a gunrunnerjohn and stan2004 'electronic project plans and parts lists' forum added somewhere here. ![]()

Get a bridge rectifier and a capacitor for each relay.

Why? That's very wasteful of resources. Since the logical way to do wiring is to have all the relays in one or two locations, it would be a great savings just to provide a single D-C supply, either from a suitable COTS (commercial off the shelf) power unit, or derived from a channel from an A-C train transformer, with ONE rectifier bridge and ONE capacitor. Tie one output of the D-C supply to the return traction power supply, and then anywhere you need to do D-C signalling, you've got the power right where you need it.

Get a bridge rectifier and a capacitor for each relay.

Why? That's very wasteful of resources. Since the logical way to do wiring is to have all the relays in one or two locations, it would be a great savings just to provide a single D-C supply, either from a suitable COTS (commercial off the shelf) power unit, or derived from a channel from an A-C train transformer, with ONE rectifier bridge and ONE capacitor. Tie one output of the D-C supply to the return traction power supply, and then anywhere you need to do D-C signalling, you've got the power right where you need it.

Well - As I see it - each control rail needs to be isolated with its relay for that block or control rail - For the typical 3 Rail Layout Track power is AC - Bridge rectifier needed with DC Relays. If you introduce DC power to the track - wont all the whistle tenders sound off ?

If you introduce DC power to the track - wont all the whistle tenders sound off ?

No.

I did not say "introduce D-C power to the track." I said provide one centralized D-C supply for all the relays (as opposed to individual bridges and caps) with a common return to the traction supply.

...provide a single D-C supply, either from a suitable COTS (commercial off the shelf) power unit, or derived from a channel from an A-C train transformer, with ONE rectifier bridge and ONE capacitor. Tie one output of the D-C supply to the return traction power supply...

Just to be clear, if generating this new DC supply using a bridge rectifier "from a channel" of the AC transformer don't you have the problem that many/most multi-output train transformers connect the returns internally? I can see it if you only use a diode (half-wave) rather than a bridge to create the new DC supply.

Separately, I suggest each relay still needs a capacitor for anti-chatter from noisy wheels/track..and why not a small resistor as GRJ suggests for anti-arcing.

If you introduce DC power to the track - wont all the whistle tenders sound off ?

No.

I did not say "introduce D-C power to the track." I said provide one centralized D-C supply for all the relays (as opposed to individual bridges and caps) with a common return to the traction supply.

OK -

What do you mean by traction supply ? you mean track power ?

I don't see how the AC track power from many different control rail can be run to only one bridge rectifier then to the relay - or relays ? If all relays are tied to one bridge rectifier then all relays would work at the same time. I'm missing something in your description of how you set up many different control rails so each control rail activates one relay .

"...if generating this new DC supply using a bridge rectifier "from a channel" of the AC transformer don't you have the problem that many/most multi-output train transformers connect the returns internally?"

I did not say "*THE* transformer" I said "*A* transformer" meaning that I suggest that you use a spare output of a spare transformer that is not being used for traction power. This separate A-C supply can be used to provide the source of electricity via a bridge and capacitor, to create your centralized D-C supply to operate all the relays on your layout. It would be unnecessary to create a common return from the A-C *INPUT* with the traction supply, and in fact, would be inadvisable for the reasons that you stated. The common return is the wire that interconnects the *OUTPUT* of the D-C supply to the outside running rail terminal on the transformer used for traction supply.

What do you mean by traction supply ? you mean track power ?

I don't see how the AC track power from many different control rail can be run to only one bridge rectifier then to the relay - or relays ? If all relays are tied to one bridge rectifier then all relays would work at the same time. I'm missing something in your description of how you set up many different control rails so each control rail activates one relay .

Q. What do you mean by traction supply ? you mean track power?

A. Traction power is the railroad industry term for the power that operates the traction motors. I prefer to use that term, rather than the ambiguous term "track power" which can mean anything from traction power to signal power, to signal ground, to anti-derail wire, etc.

Q. I don't see how the AC track power from many different control rail can be run to only one bridge rectifier then to the relay - or relays ?

A. I did not say that. I do not mean that. You are putting too many words into a simple concept.

First, "AC track power from many different control rail(s) " is *NOT* "being run to only one bridge rectifier." The track COMMON, via the wheels of the train, is being run to one of the relay coil terminals. Relay D-C power is waiting on the other relay coil terminal. It is also waiting on *ALL* the relay coils. That is why it is called a common supply, (saving the need for many individual bridge rectifiers.) Since the D-C supply and the traction power share a common return, the relay operates when the wheels bridge the rails.

Q. If all relays are tied to one bridge rectifier then all relays would work at the same time.

A. No, each relay has its own "operate" wire (from its own section of track) to one side of each coil, and all the relays are supplied with D-C power on their other coil wires.

Q. I'm missing something in your description of how you set up many different control rails so each control rail activates one relay.

A. Here's the diagram: (draw it out on a piece of paper to understand it better)

COMMON lead from transformer > "regular" outside rail > wheels > insulated rail > control wire back > relay coil > HOT side of D-C supply (or A-C supply, if you prefer) > output of supply > back to COMMON. It's the same simple circuit that you seem to understand.

I think you are getting confused by the addition of the idea of using D-C instead of A-C.

Each insulated rail has its own control wire, which goes to its own relay coil. There is no interference, any more than there is when you turn on the light in your bathroom, and the light in the living room. They both have separate OPERATE leads (from separate switches) but they both have a COMMON wire (the neutral bus in your circuit breaker panel). For simple electrical components to interfere with each other, or to interact, they need to have TWO common wires. Think "horn" and "tail lights" in your car. Each has its own OPERATE wire, and they share a common chassis ground.

"...if generating this new DC supply using a bridge rectifier "from a channel" of the AC transformer don't you have the problem that many/most multi-output train transformers connect the returns internally?"

I did not say "*THE* transformer" I said "*A* transformer" meaning that I suggest that you use a spare output of a spare transformer that is not being used for traction power. This separate A-C supply can be used to provide the source of electricity via a bridge and capacitor, to create your centralized D-C supply to operate all the relays on your layout. It would be unnecessary to create a common return from the A-C *INPUT* with the traction supply, and in fact, would be inadvisable for the reasons that you stated. The common return is the wire that interconnects the *OUTPUT* of the D-C supply to the outside running rail terminal on the transformer used for traction supply.

Sorry - but I'm lost trying to Follow this ?

I dont know what traction supply is ? Are you talking about Command control or the other modern three rail train control systems ? My drawing that I posted above I am showing old school Lionel Power to the track. If you could post a drawing - that would help -

Steve

Q. I'm missing something in your description of how you set up many different control rails so each control rail activates one relay.

A. Here's the diagram: (draw it out on a piece of paper to understand it better)

COMMON lead from transformer > "regular" outside rail > wheels > insulated rail > control wire back > relay coil > HOT side of D-C supply (or A-C supply, if you prefer) > output of supply > back to COMMON. It's the same simple circuit that you seem to understand.

I think you are getting confused by the addition of the idea of using D-C instead of A-C.

Each insulated rail has its own control wire, which goes to its own relay coil. There is no interference, any more than there is when you turn on the light in your bathroom, and the light in the living room. They both have separate OPERATE leads (from separate switches) but they both have a COMMON wire (the neutral bus in your circuit breaker panel). For simple electrical components to interfere with each other, or to interact, they need to have TWO common wires. Think "horn" and "tail lights" in your car. Each has its own OPERATE wire, and they share a common chassis ground.

I know I have read this here before, but I forget? I think you are saying it is ok for the A/C and D/C to share the same common? I think that is what I remember as being correct, but could you clarify? Maybe I will remember it this time...![]()

I think you are saying it is ok for the A/C and D/C to share the same common?

Exactly. Just as the headlights and the radio and the horn in your car, share a common return ("ground") wire...or the lights in your house and the lights in your neighbor's house, and the street lights outside your bedroom window, share a common ("Neutral") wire.

Simply, my agenda was, and is, to try to explain why MANY individual bridge rectifiers and MANY individual filter capacitors are not necessary.

A centralized D-C supply, for relays (if you want to use D-C relays) is cheaper to build (or buy) using ONE rectifier bridge and ONE capacitor than it is to install MANY rectifiers and MANY capacitors on MANY relays. It is just a wasteful method to do this type of signalling.

I have been taken to task at least three times in the last few months for asserting that a D-C supply can work with A-C traction power, using a common return. Instead of my needing to re-type my remarks, I suggest that you make a visit to the archives.

If all relays are tied to one bridge rectifier then all relays would work at the same time. I'm missing something in your description of how you set up many different control rails so each control rail activates one relay .

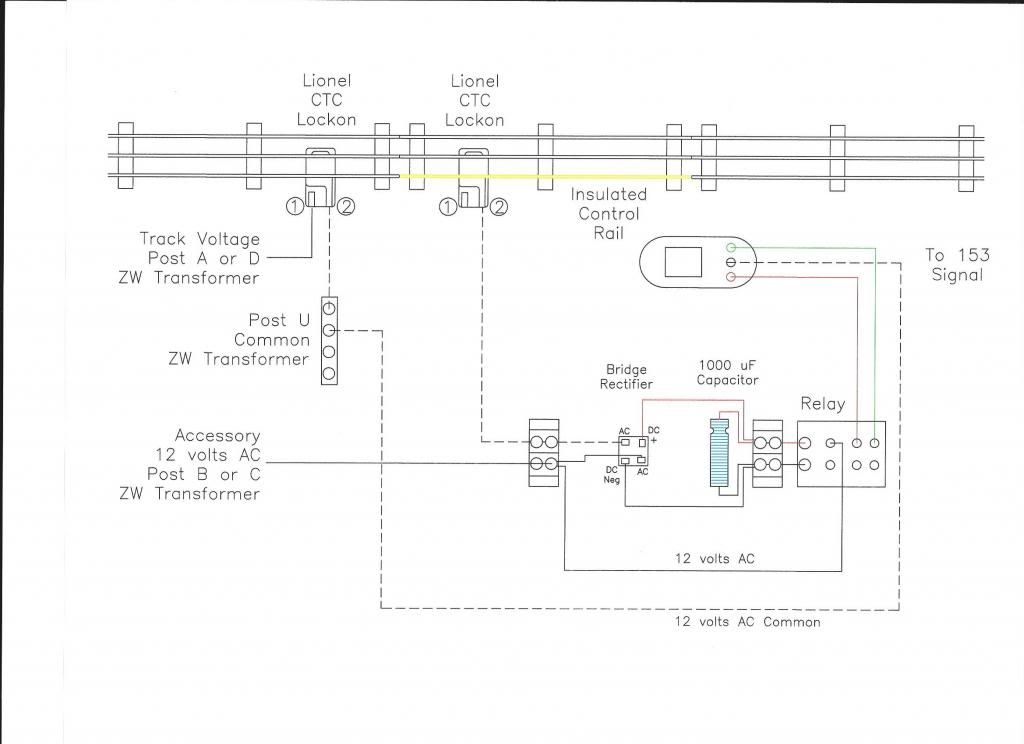

Yes, in this case traction supply is track power coming from the "THE" main train transformer. You then use "A" separate transformer that generates a "community" DC supply using a bridge-rectifier and capacitor. This DC output is labeled DC+ and DC- in the diagram. All the relays (only 3 shown here) have one side of their coil tied to DC+. When a wheel-truck bridges the gap, the corresponding relay now receives DC- relay closes...the other relays are not affected. If you follow the wiring of the center relay in the diagram through the wheel axle, you can see only that relay will get coil voltage and the other two do not.

As I suggested previously, this "community" DC supply can also come from a 12V DC wall-wart (a few bucks) which also generates an electrically-isolated source of DC.

As not to pile on additional confusion, this diagram does not address anti-chatter which must be solved on a per-relay basis (e.g., resistor plus cap).

One's first thought might be to simply use the Accessory Output channel from their transformer to feed this bridge rectifier. You cannot do this using the "community" bridge rectifier method for reasons discussed above. That is, most train transformers internally connect the AC return/ground outputs together. This means they are not "electrically isolated". This electrical isolation is necessary to allow the traction/track power supply and bridge-rectifier-derived DC relay supply to share the outer-rail without "bothering" each other.

Attachments

Stan, thank you for creating the diagram, and adding to (simplifying) my explanation. You have saved me many electrons.

BTW, may I ask what drafting program you use?

BTW, may I ask what drafting program you use?

Freeware...suitable for basic "old-school" electrical diagrams: