The domes are complete. I used several different techniques, not shown in the photos to get the end result.

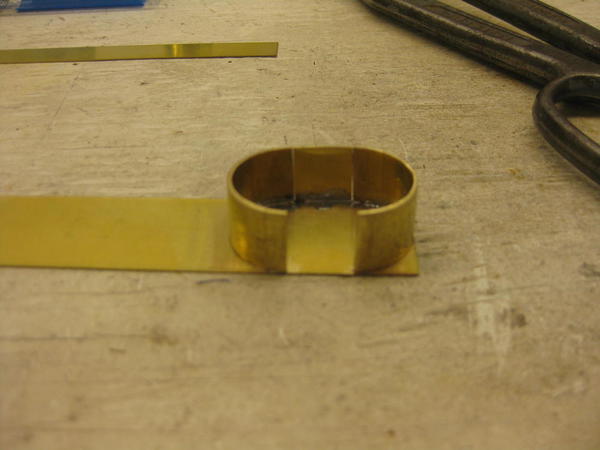

Using the brass tube from Online Metals, I cut a piece slightly taller than needed. My big hands can't hold on to those little pieces and later I cut it down to correct dimensions (below).

Here's how the the tube compared to the dome I was making, I couldn't keep the radius concentric on each end and kept making 'egg' shaped domes. I'll try Bob's technique on the next project (below):

I marked center OD of the tube and used tape to serve as a vertical cutting guide. My saw quit so I used a razor saw...ugh. After cutting the tube vertically, it 'relaxed' and was bigger than original (below).

The brass sheet was the same width as my original tube diameter. Hard to see in the picture, but I measured and scribed an equal distant line, equal to the tube radius on each end of the brass sheet. This aided in accurate placement of the tube and 'scaled' the dome to the correct length and width. I used the Vise-a-grips to pull the tube back to the correct diameter for soldering (below).

My 'high speed press' I use to hold parts:

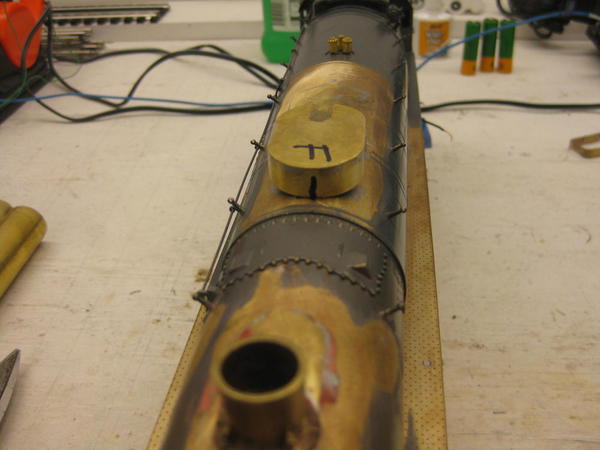

The straight section of the dome soldered in place:

The other side:

Cut dome from sheet and started rounding the corners:

Scribed a line around dome and marked with tape to get the correct height. Cut dome:

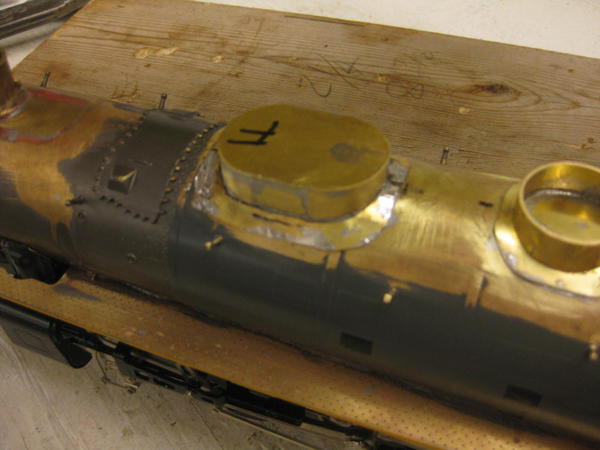

Found center of boiler/dome and marked them for reference:

Here, I started to profile dome to boiler using a cutting tool, anyone notice I missed something important?

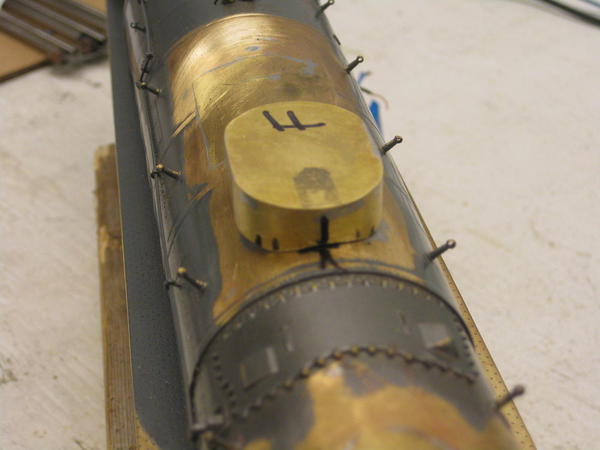

Started on smaller second dome:

Profiled it and added the flange:

Rounded the edges of the flange:

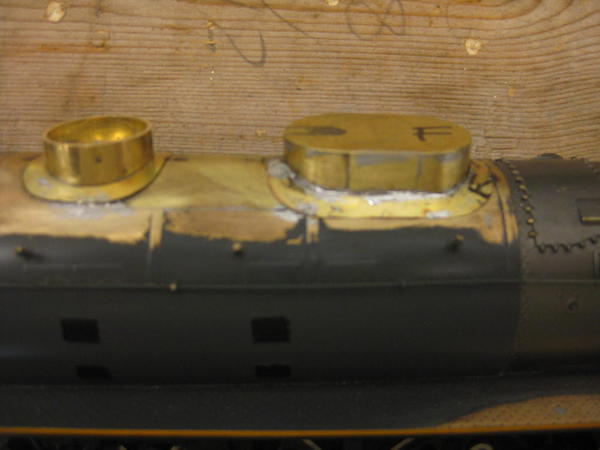

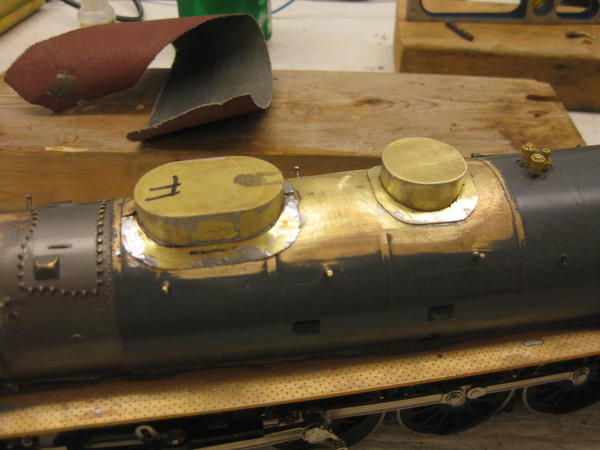

Second dome installed:

At this point, I was marveling at my work when I realized I forgot the flange on the first dome!

So, here's how I corrected it. Using masking tape, I made a pattern and transferred it to the brass sheet. I decided it would be difficult to make the flange in one piece and slide over the dome to fit, so I cut it in half. Then cut out the marked section, filed to fit, and installed.

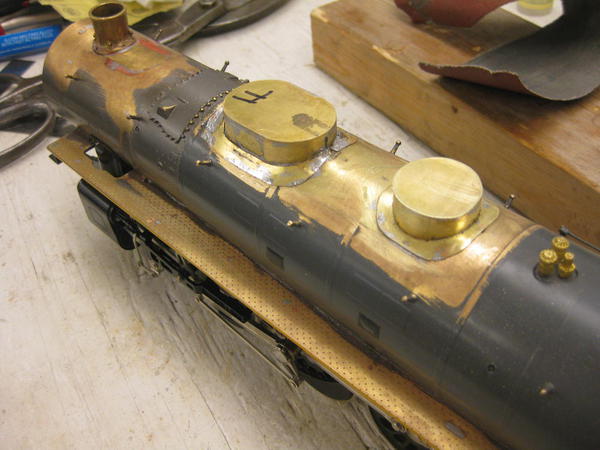

The final dome/flanges:

Learned a lot and tried different techniques. In the future, I hope to have a lathe to do the round domes. Also, I won't forget the flange again, it was a lot of extra effort to make it that way, but well worth it. A little filler at the dome/flange transition and it'll be done.

I'm very pleased with the results. As Ron said, sometime attempts 3-5 are just practice runs!

Firewood, not sure you're still following along, but thanks for the article. I've printed it out and spent time reading it. The techniques can be used in brass also. It should help when I'm ready to do a complete scratch built locomotive.

Now on to the detail parts and stuff I'm really looking forward to building.