Hi everyone, I am going to attempt to scratch build an O gauge depot. This is going to be my first attempt so I am going to continuously get on this Forum and glean as much info as I can from all of you scracthbuilding pros. I bought an HO kit which I will use as my blueprints. The depot is mainly brick with a shingled roof. My first questions are: Do I build this with wood or with plastic? What are the pros and cons of each? Should I use 1/48 scale or can I cut it in half for 1:43.5? This will keep me going for awhile. I thank all in advance for your help.

Replies sorted oldest to newest

For one thing, Paul, 1:43 would be larger than "0" gauge which is 1:48. To make it smaller in relation to other "0" gauge items you'd need to be in 1:50, or 1:55 scale. 1:64 is "S" gauge and would probably be too small for your layout.

Scratchbuilding can be difficult but, on the other hand, the results, if done well can be a source of pride. Is this depot the one in Wausau that I think you mentioned some time back? Be a nice project, but probably bigger than what you'd expect until you actually lay it out on paper.

Paul Fischer

Paul,

One of these books would be a good investment to get you started on the right foot:

You can probably find one of these or similar at the local hobby shop.![]()

Jim

Paul, welcome to the wonderful world of scratchbuilding. With every building your skills will improve and your results will be a one of a kind that few can match. I envite you to look on my web site www.westportmodelworks.com and the 'my projects' pages for the techniques I use.

Les Lewis

Coloradohiraile and Les, I appreciate your replies. I don't have the HO kit yet but I have a 1/16" = 1' drawing.The drawing is 5 1/2 " wide by 1 1/8" high. So, if my math is correct, that would be 88' by 18' full size or 22" x 4 1/2". I would have plenty of space on my layout to put it there. I have used micro-mark brick plastic sheet and some plastruct plastic sheets of diamond tread. I also used "gator board" for a chimney with micro-mark brick over it. What wood do you suggest? I have built Bar Mills, Korber, Ameri-towne, Berkshire Valley and some other kits for my layout. All and any suggestions are looked forward to. Do you use as much commercial parts as possible?

I mean like grandt windows. Thanks again and I will be getting back to you.

Paul, if you're building a brick building, some of it may be of wood, mostly basswood in train model making, (not balsa) like board and batten or clapboard, eaves, and sheets of that are available from Micromark. Cheap and quick sources for the 1/4" square rod, and larger, for framing are Home Depot or Lowe's. They don't, in my experience, carry smaller sizes such as 1/8", but MicroMark carries that, too. LHS never seem to restock it. I would use Grandtline or Tichy Train Group windows if you can find any close to what you need. Grandt has more, but you

will need those plans in O scale to measure the windows, count them, and then make

a list of sizes/styles you need, hoping none are oddball ones you will have to build up.

You can cut, section, and reglue those plastic ones to meet some needs. If you've done a press and stick kit with built up paper windows, you will be able to make odd ball ones if forced to. I usually substitute Tichy or Grandt to gain time if nothing else,

IF they have ones that are close, in a press and stick kit. Since you've built that variety of kits, you aren't a novice as I first supposed, and looking at how the kits

did it will help. I can never find O scale parts like windows in most hobby shops, so

you may have to order those directly from Tichy and Grandtline. There are other

brands of brick siding from some smaller kit builders, but you will have to surf the

net to find those. I have heard some mentioned on here in other posts but haven't

yet used them. I use the yellow carpenter's glue for wood, and red tube Testor's

for styrene and styrene on wood, or, if strength is a concern, I use two part epoxy.

the debate of wood vs. styrene is an on-going one and seems more a matter of preference. personally, I prefer wood as it's very forgiving, you can use water based glues like Aileen's tacky glue andsince I like my structures old and run down, wood is very easy to weather with A&I, chalks and dry brushing. for wood sources, try northeastern scale models, mt albert or micro-mark. all have a good variety. you can even get brick wall designs in wood from monster model works, rusty stumps and model tech studios. scratch building is to me one of the most satisfying arts of the hobby. overall size, within reason, doesn't really count for much unless you are duplicating a prototype building. it is primarily the windows and doors that determine whether the scale of the structure looks right. and to my eyes, if it looks right, it is. have fun.

jerrman

I'm with Jerrman on the virtues of wood over plastic. It really depends on the look you are going for. If you want a "new" or "modern" look, styrene is probably best. But if you want your layout to have an older, "lived-in" look, wood is hard to beat.

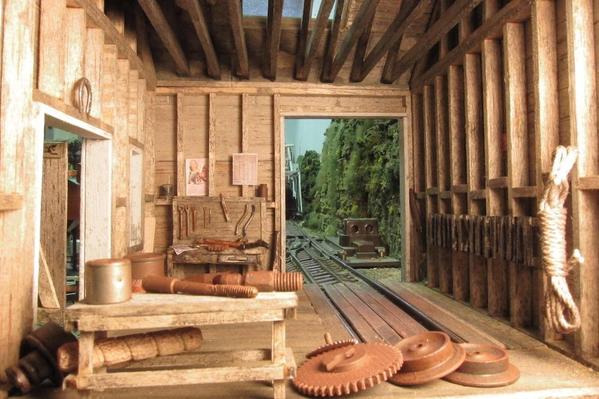

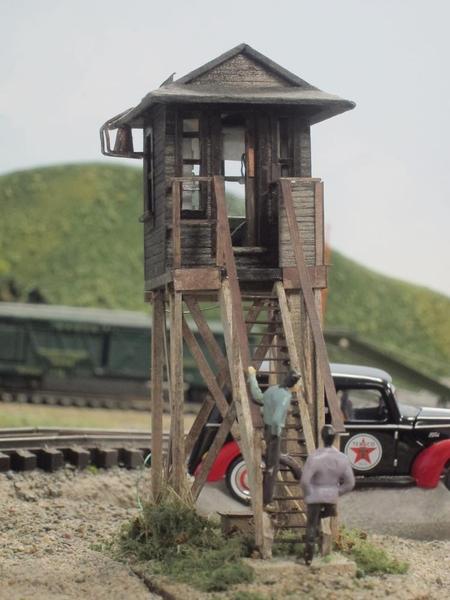

I am in the minority around here, but I think that balsa gets a bad rap. I use it a lot. It is very easy to work with, easier to find than basswood, and cheap. It definitely gives a softer effect, so is most appropriate for weathered buildings. Both of these buildings are almost completely balsa:

Also, don't forget paper and card stock. Buy a tablet of heavyweight watercolor paper or bristol board and you can do all kinds of stuff with it. The siding on this building is made of painted strips of bristol over foam core:

It is also quite possible to do your own windows and other wood trim using paper and bristol board. Tedious, and it won't look quite as precise as purchased model millwork, but again, depending on the look you want, that can be a good thing.

But, most importantly, as everybody says: do what you enjoy and have fun!

Attachments

wow, Pete, if those structures don't speak to the advantages of wood and cardstock, I don't know what does. I once had the opportunity to visit george sellios' layout, whom I consider one of the best in the world (but you have to love the run down look to really appreciate it). I asked him if he ever used styrene in his structures and he said (and I'm paraphrasing here) why would I use styrene to simulate wood when I can just use...wood. H-m-m.

but, each to his own.

anyway, great work, Pete.

Jerrman

I see the worth of Balsa in many instances....the best scratch building originates from the open mind of the builder....everything should be considered and tried in pursuit of authentic construction.

In this photo of an interior I recently completed, there is balsa, basswood, cardstock, birch veneer, hardwood scraps, metal, plastic, and paper...the point is use your imagination to the max...you'll be surprised what you can create..

Bob

Attachments

Bob and Pete......Beautiful work guys! I especially like the interior shot Bob.

Alan

Why would you use wood when you can use styrene? ![]()

I have never fully understood the desire to use styrene to emulate a wood surface....

However, brick is another surface entirely and is also somewhat porous in reality which tends to give it its characteristic appearances. Not sure if anyone mentioned it yet, but plaster might seem good for brick.

Anybody can make wood look like wood. ![]()

Anybody can make wood look like wood. ![]()

Hence the attractiveness of using wood to emulate wood, ![]()

I'm getting a lot of good info from all of you. Have any of you used what Micro-mark calls "Gator Board"? It is foam board with either tan or black paper on both sides. I have used it for foundations and to make a 50' scale chimney which I wrapped with plastruct plastic brick sheeting. I'm thinking of using it for the framework of my depot seeing as it too will have a brick facing. Any comments?

Paul...from what I understand Gator Board is suppose to be an improved version of common foam board. Foam board warps when used in any water based moisture situation unless it is braced very well, and they say Gator Board does not. Warpage in model construction can be frustrating. But I have not tried gator board personally, so I cannot give an opinion.

Bob

I've worked with both. Styrene is easy to cut since you scribe and snap. Styrene also glues very quickly using the high-volatile solvent-based plastic welding agents like Tenax. I use a touch-n-flow capillary feed glue applicator that lets you put a very controlled amount of glue right in the joint. I also build in wood using Aleen's tacky glue. My biggest styrene project (not yet complete) is a Victorian RR station that was on the New York, Ontario and Western RR. It was an article in Model Railroader in HO scale. I scanned the plans and scaled them up (181%) in the computer. It's a very complex build with siding changing direction from horizontal to vertical, and having an English Tudor half-framed construction.

These pictures show a technique you can use only with styrene. It enables you to make perfectly sized and squared window openings. You scribe all the horizontal and vertical boundaries between windows and walls, break it all apart and then glue it together with plastic welding solvent, but without the pieces for the windows. The glue dries very quick. With this design, since the siding changed direction between floors, it was the only way to do it. Try doing that with wood.

This is not a cheap replacement for a craftsman kit. I've got almost $200 in styrene sheet and bars, plus a ton of Grandt Line windows and doors, and lots of hours already spent to get it this far. I'm almost done fitting the roofs. I have to build a second floor. There's a large covered waiting area on the front and back which has a standing seam roof, and then there's the multi-color paint job...whew! The hardest part so far, is the roof. I've learned a lot on this project and the next one will be easier. Oh... and then there's the interior...

Attachments

There is some excellent work posted here! I find that I use the same materials over and over, maybe limiting myself. After seeing the above results achieved with other materials, I will give them a try.

Again, thanks to all who have posted photos here!

Dave

Paul,

You will love scratchbuilding. The "I made that factor" is wonderful. Don't be afraid to do things more than once till you get it right.

Go back to Mainline Modeler and read Bob Hundman's articles on working with styrene, it really is a good medium to use. Between Evergreen, Plastruct and JTT lots of basic material is available. Tichy, Grandt and others make lots of window and door castings as well as other stuff.

If you use the score and snap, then put it back together method for the openings laminate all the parts to .005 or .010 sheet. It helps to keep everything together. After everything is dry cut the openings out with a new exacto blade, then install the castings.

Good luck and happy modeling.

George Lasley

Yes!

I actually believe that this is the one great secret that differentiates the successful scratchbuilders from those who say "I don't have the talent." We all screw up all the time. All it takes is to resist the impulse to say "maybe that is good enough" and to instead tear it out and immediately do it again. The second try is almost always much faster than the first (because working out the method is usually the time-consuming part). If you don't let the "oopses" accumulate, anybody can do great work.

I admit that I sometimes have trouble following my own advice, but I just keep reminding myself that the details matter and try to always redo the marginal work. I often think of the time that Zett tore up a major part of his amazing Union Station build because of a measurement problem that nobody but he would have ever noticed. Real inspiration.

I absolutely agree. Almost nothing I make the first time is as good as I want it, and the more times I repeat it, the better it gets. I was working on a large RC model of a B-17E. The changes I made to the design caused me to make many versions of some parts before they came out as I wanted. People say, "You have a lot of patience to build great models." It's not patience, it's stubbornness. I refuse to let the project defeat me. I will keep at it until it works out. That's not patience. That's drive.

Again, Thanks everyone for your imput. I had some sheets of gatorboard that I will use. I got my Wathers HO depot kit which is a replica of the Wausau, WI Milwaukee Road one that I have wanted to scratchbuild. Today I converted about 15 walls from the kit to O scale onto gatorboard. Tomorrow I will cut the pieces out and glue them together. I'm not going to finish the interior so I don't think windows will be a problem with the gatorboard. I'll take some pix and post them. Plastruct has red brick plastic sheets and gray shingles, Micro-mark has white plastic brick sheets and white plastic shingles. They also have red paper brick with adhesive backing and gray paper shingles with adhesive backing, My completed model will have Brown brick and Green shingles.What are your thoughts on these choices of bricks and shingles and what do you suggest for coloring the brick brown and shingles green? This should keep all of you and me busy until I am ready to move to a different phase of the building.

Well I am a day late but here are some pix of my Wausau depot being built. I took the HO pieces, measured them and converted to O gauge which I then cut out of "Gator Board" 3/16" thick. This stuff is easy to work with. I just need to remember to knock off 3/16" where necessary. When I get further along I will check out both Grandt and Tichy for doors and windows. I will use either Plastruct or Micro-Mark sheets of plastic bricks and shingles.

Any comments, positive or negative, and suggestions will be greatly appreciated.