My old Weller soldering iron finally bit the dust and needs to be replaced. I was wondering what soldering irons or stations some of you are using and with both positive and negative results will be appreciated. I have moderate soldering skills and looking to do more upgrade on my older locos and passenger cars. I also like the challenges of rebuilding and upgrading my fleet and the more seasoned items you can find in our hobby that need to be reborn. I value the knowledge and experience of the all you members here on the forum. You are a Great resource to me with my railroad and I know to the others as well. Thanks

Replies sorted oldest to newest

smilesrs,

You failed to say what the heat range of your Weller. I always buy a copy exactly like the one being replaced. After all you are used to that type and heat range. Down the road purchase the next heat range up. Just a thought due to the fact that you're used to the old unit while it was giving up the ghost.

Sorry, it was the W100P 100 Watt and I'm thinking of going to the digital type.

I really like my Hakko FX888D, I replaced an aging but still working Weller soldering station with it, and I have to say it's worked out well. A bonus of the Hakko is you can actually calibrate the tip temperature so it matches what the display says, an important feature for soldering circuit boards and other delicate jobs.

John,

At 70 watts input power, it would seem that your unit is designed for circuit board work, and may not have the power to do larger jobs. What is your experience with the unit in soldering parts such as a roller pickup with a large mass that would act like a heat sink?

Nice unit at a good price if it can do the job of higher power units.

Larry

I got a Weller analog soldering station. If I had it to do over, I would get the Hakko that gunrunnerjohn recommended above. That's a very nice setup and not a great deal more expensive than the Weller I have. I may yet end up getting the Hakko and putting my Weller in back-up reserve service.

Larry, when you're talking about soldering irons, IMO one size doesn't really fit all.

I use the Hakko for my bench work for wiring, circuit boards, etc. 95% of my soldering is accomplished with that iron. You'd be surprised how much heat you can get out of a 70W iron. For stuff that requires more heat, I use the 100/140W Weller gun. I broke it out yesterday to solder some brass tubing for a smoke unit installation.

I don't know of any 100W or more soldering irons or stations at a reasonable price that would be suitable for all tasks.

Thanks for the feedback Gentlemen. I'm gonna look at some that you have suggested and by the way; do you find one certain tip type or style to work better for a variety of tasks over others.

I use a fine point tip for most of my work, I can change to a small chisel tip for heavier work. Typically, if I need the larger tip, I usually just grab the soldering gun. I do a lot of wiring and circuit board work, so the pointed tip works well for most of my uses.

The gun can be had for $30-40, and I've never come across any task that it wouldn't handle. If I need more than 140 watts for soldering something, it's time to get out my propane torch. ![]()

I recommend care when selecting the soldering station, good tools are worth the price. I made the mistake of first buying an off-brand soldering station and I regretted it. It quickly got retired and I decided to bite the bullet and get the Hakko. I don't regret the choice, it's just a lot more pleasant to use good tools. I have the off-brand one as a backup if I ever need it.

I bought a Hakko station (888D) about 8 months ago. Love it. I thought I would still be using my Weller gun for "heavy" stuff, but haven't had to yet. This is a terrific tool.

Roger

I bought a Snap-On r450b soldering gun. It came with 3 tip sizes. It's a single post gun. Does a real good job. I have a soldering station i bought off Ebay. It's a 937D YIHUA esd station, esd safe. Haven't used it yet. Is this a good unit? I don't know much about these soldering stations.

I don't know anything about the Yihua soldering stations. The specs for this one is 45 watts, I like the Hakko because it has 70 watts and holds the temperature right on. I also like the fact that I can calibrate the tip temperature so it's spot-on to what the display reads.

I don't know anything about the Yihua soldering stations. The specs for this one is 45 watts, I like the Hakko because it has 70 watts and holds the temperature right on. I also like the fact that I can calibrate the tip temperature so it's spot-on to what the display reads.

Thanks John, i can calibrate this station too, and it has a temp display on it. It appears to be a well made unit.

If it works for you, that's all that counts. ![]() I've never seen one, so I can't really give a factual review.

I've never seen one, so I can't really give a factual review.

John, what size tip for the FX888D do you recommend for soldering 16 awg wire to Atlas rails ?

Thanks,

Mike Miller

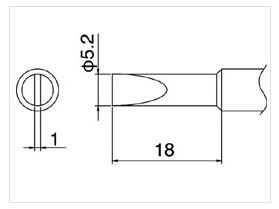

For rails, I'd probably use the chisel tip. This one is appropriate for track work. It's the T18-S3 Shape-S3 one.

Attachments

This is the one we use Its awesome Has adjustable temperature and a myriad of different tips for different applications Its the Hakko FX951

Attachments

I have a different Hakko than bluelinec, I think its no longer made.

We use Hakko at work for adding thru hole components on circuit boards and some cable assemblies.

I like the interchangeable tips, but I will admit the initial outlay can be costly. Some vendor had a two-for-one sale on Hakko when it first came out, and I went in with CharlieT. Not sure if he really got the use out of it that I did.

The Hakko FX888D is less than $100, and it's a tool that will last you for many years. I think it's well worth the minimal investment.

Hi Guys

About solder, what's my best ratio to use for wire to wire and wire to rail?

Tks

Tommy

I generaly use the smallest dia rosen core solder i can find. That way i don't overheat the parts i am soldering. Radio Shack sells it.

I use the 63/37 for most of my work. For rails, I have a roll of .031 diameter, for PCB work, I use a finer pitch .021 diameter solder.

I switched over from 60/40 to 63/37 on the recommendation of Gunrunnerjohn about a year ago and never looked back. Wonderful stuff!

-Roger

I use the 63/37 for most of my work. For rails, I have a roll of .031 diameter, for PCB work, I use a finer pitch .021 diameter solder.

You answered the question better than i did John. Plus i learned something.

The benefit of 63/37 is that it is eutectic, which means that it changes from liquid to solid at a single temperature, 60/40 is non-eutectic and has a temperature range where it's a pasty mess. If you move the joint during the solidification, you will probably get a cold solder joint. The eutectic alloy greatly reduces the possibility of cold solder joints as it goes directly from liquid to solid at a single temperature. Also, the melting point of 63/37 is the lowest of common solder alloys at 361 °F. 60/40 melts (and solidifies) in the range of 361–374 °F.

I have a different Hakko than bluelinec, I think its no longer made.

We use Hakko at work for adding thru hole components on circuit boards and some cable assemblies.

I like the interchangeable tips, but I will admit the initial outlay can be costly. Some vendor had a two-for-one sale on Hakko when it first came out, and I went in with CharlieT. Not sure if he really got the use out of it that I did.

Hello Micheal, good to hear from you.

I just saw this post and will echo what everyone else said about the Hakko. Working with the Hakko has been an absolute pleasure.

I came from a Weller station that I "thought" was fine. After I tried the Hakko I was hooked. Maybe the best piece of advice I can give is that if you in the market for a quality soldering station try the Hakko and you will not be sorry.

Charlie

Its the Hakko FX951. I just got this Soldering set up a month ago. Can't wait to use it. My old Weller soldering iron finally bit the dust Too.

Thanks Guys

Great info, I learn so much every visit

Tommy

gunrunnerjohn posted:The Hakko FX888D is less than $100, and it's a tool that will last you for many years. I think it's well worth the minimal investment.

I'm seeing a HAKKO 191 temperature tester on "that auction site" ... it comes with 10 "testing sensors" ... is this a piece-a-junk or a good deal? Does the 10 testers mean that after using it 10 times one needs to buy more "testing sensors?" I notice it is only listed as a C* measuring, not F* ... are they all just in C* degree measurement?

You use the sensors many times, I'm only on my second one and I've been using my tester for several years, probably about once a month. Ten sensors will last for years.

For $200+ you can have Fahrenheit measurement, I prefer the cheap price and a free temperature conversion tool or table. ![]()

I also have the temp sensor (as a result of GRJ's recommendation) and it's excellent. A year in.....same sensor. I also bought a second iron for my station with a fine tip, so in the middle of a job, I don't have to try to exchange tips on a hot iron. Plug and play.

Roger

Hello My Friends, The soldering irons I like is called American Beauty or www.americanbeautytools.com. I think they are the best solder irons you can buy they can be expensive too. But do a lot of soldering I have the best you can buy in solder irons. I also have Weller solder guns too as backup . The American Beauty will last you a life time and longer. They have good selection of different wattage solder irons for different applications of what you need. They are professional grade soldering irons. Thanks longbow57ca.

No offense longbow57ca, but let's agree to disagree with your assessment of their soldering irons. Since we're talking soldering stations, I picked the one that's closest to the Hakko FX888D for comparison, the Model V36GL3 60 Watt Industrial Grade Soldering Station. It's basically twice the price of the Hakko FX888D, so you're right about them being expensive. However, IMO, that's where the "right" ends.

The Hakko has a real temperature display that is actually displaying the actual tip temperature. In addition, you have provisions for calibrating the tip temperature when you change tips or handles. The American Beauty has an un-calibrated analog dial and makes this statement in their user's manual.

The proper setting will be application dependent and

determined through trial and error or by measuring tip

temperature using an external device.

Say what? I'm soldering some delicate SMT components to a PCB and I'm supposed to guess at the tip temperature? How about holding the temperature as you work, I don't see any provision to keep the temperature constant while you work with varying heat loads. With the Hakko, you get an instant feedback of the true tip temperature, and you can see if it varies.

Truthfully, I don't see how these two products are anywhere close to equal, and the superior product would clearly be the Hakko soldering station.

Hello GUNRUNNERJOHN, No offense taken and thank you for answering me. That Hakko sounds like good soldering iron for the money my friend. Thanks longbow57ca.

Kerrigan posted:gunrunnerjohn posted:The Hakko FX888D is less than $100, and it's a tool that will last you for many years. I think it's well worth the minimal investment.

I'm seeing a HAKKO 191 temperature tester on "that auction site" ... it comes with 10 "testing sensors" ... is this a piece-a-junk or a good deal? Does the 10 testers mean that after using it 10 times one needs to buy more "testing sensors?" I notice it is only listed as a C* measuring, not F* ... are they all just in C* degree measurement?

C times 9/5 plus 32 equals F

John,

What's the best source for the 63/37? I ordered the Chinese calibrator from Ebay you recommended. I always enjoy your threads since I learn something new with each one.

Hmm...

Interesting... C times 10/5 minus 1/10 C plus 32, eh?

And I always find these threads cost me money ![]() and where to sell my Wellers...

and where to sell my Wellers...

BradFish1 posted:What's the best source for the 63/37? I ordered the Chinese calibrator from Ebay you recommended. I always enjoy your threads since I learn something new with each one.

Thanks. ![]() I confess that I haven't bought solder in a while, I'm still working on two 1 pound rolls I got some time back. I'd just plug it into Google, Kester 63/37 Rosin Core, and I find this is a good price: Kester 44 Rosin Core Solder 63/37 .031" 1 lb. Spool

I confess that I haven't bought solder in a while, I'm still working on two 1 pound rolls I got some time back. I'd just plug it into Google, Kester 63/37 Rosin Core, and I find this is a good price: Kester 44 Rosin Core Solder 63/37 .031" 1 lb. Spool

Slightly better price, .031 diameter, eBay #: 322310408145, and for .015" diameter, use eBay #: 351777770333

PLCProf posted:For mental calculations, double the C temp, subtract 10 percent and add 32. Easier than multiplying by 9 and dividing by 5.

100 *2 =200, subtract 10% = 180, add 32 = 212.

Very clever, I'm keeping that in mind. I've always done it the long way! ![]()

Gilly@N&W posted:I use this.. Weller

Really simplifies things not having to deal with a power cord around the layout.

A butane iron is not really that useful doing delicate soldering, you have very little temperature regulation. I can see the damage I'd do with one of these on a PCB. ![]()

BradFish1 posted:John,

What's the best source for the 63/37? I ordered the Chinese calibrator from Ebay you recommended. I always enjoy your threads since I learn something new with each one.

https://www.amazon.com/Kester-...+.031%22+1+lb.+Spool

22 dollars plus shipping or prime...

Or......just keep this handy on Favorites below your browser bar. Plug in the desired F temp and instant degrees C...

http://fahrenheittocelsius.com

Roger

gunrunnerjohn posted:Gilly@N&W posted:I use this.. Weller

Really simplifies things not having to deal with a power cord around the layout.

A butane iron is not really that useful doing delicate soldering, you have very little temperature regulation. I can see the damage I'd do with one of these on a PCB.

Yeah, I just use it for wire. When it comes to PCBs, I leave that to someone who knows what they're doing. There is a world of difference between Electrical and Electronics. I'm very comfortable in my little electrical world.

I'm sure the butane torch is handy on track and track wiring, no critical heat regulation needed. ![]()

cjack posted:Hmm...

Interesting... C times 10/5 minus 1/10 C plus 32, eh?

And I always find these threads cost me money

and where to sell my Wellers...

I have a steady supply line open to the Far East from following all these threads around here. Fortunately, most are free shipping. And these things are all usually much less than buying trains. ![]()

PLCProf's formula for C to F is a very good one as well. New to me. I am going to write that down and put a copy on the work bench in anticipation of the arrival of the Hakko calibration tool that this thread has forced me into ordering... ![]()

rtr12 posted:cjack posted:Hmm...

Interesting... C times 10/5 minus 1/10 C plus 32, eh?

And I always find these threads cost me money

and where to sell my Wellers...

I have a steady supply line open to the Far East from following all these threads around here. Fortunately, most are free shipping. And these things are all usually much less than buying trains.

PLCProf's formula for C to F is a very good one as well. New to me. I am going to write that down and put a copy on the work bench in anticipation of the arrival of the Hakko calibration tool that this thread has forced me into ordering...

Yeah. Darn these guys! I had to order one as well ..... :-)

rtr12 posted:cjack posted:Hmm...

Interesting... C times 10/5 minus 1/10 C plus 32, eh?

And I always find these threads cost me money

and where to sell my Wellers...

I have a steady supply line open to the Far East from following all these threads around here. Fortunately, most are free shipping. And these things are all usually much less than buying trains.

PLCProf's formula for C to F is a very good one as well. New to me. I am going to write that down and put a copy on the work bench in anticipation of the arrival of the Hakko calibration tool that this thread has forced me into ordering...

Actually I made a mistake in commenting on PLCProf's formula...

It's C times 10/5 minus 1/10 of 10/5 C plus 32 equals F

cjack posted:rtr12 posted:cjack posted:Hmm...

Interesting... C times 10/5 minus 1/10 C plus 32, eh?

And I always find these threads cost me money

and where to sell my Wellers...

I have a steady supply line open to the Far East from following all these threads around here. Fortunately, most are free shipping. And these things are all usually much less than buying trains.

PLCProf's formula for C to F is a very good one as well. New to me. I am going to write that down and put a copy on the work bench in anticipation of the arrival of the Hakko calibration tool that this thread has forced me into ordering...

Actually I made a mistake in commenting on PLCProf's formula...

It's C times 10/5 minus 1/10 of 10/5 C plus 32 equals F

That's no problem, easily fixed. I thought you were going to say there was a problem with my Asian supply line. ![]()

I can't tell you guys how much I enjoy this forum and most of the great nature Trainsters out here. You guys are what has made my resurgence in model railroading more FUN and enjoyable than I could have imagined. Thanks again for all your expertise, tips, and knowledge.