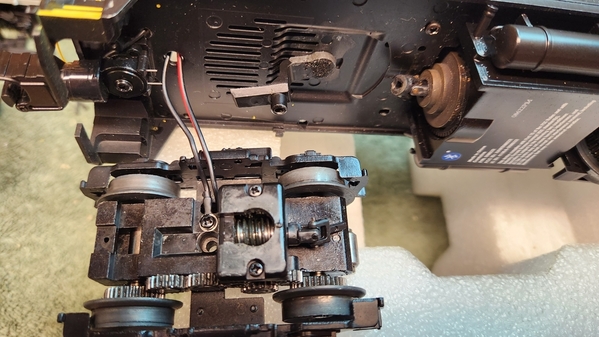

I have a new Lionel SW-1 Legacy switcher that is a bit over a year old. It had run fine (although a bit of a growler), but when I started it up yesterday, the drive wheels spun freely on the track and then the engine shut down - cab lights flashing and all that. Turning it over, I saw there was a lot of slop in the wheels that didn't allow the gears to align. Using bread clips and eClips, I got them lined up, but no joy with the slippage. I then replaced the traction tires but, again, no joy. I thought that maybe the worm drive was not seated properly and checked that. It all seemed to be in order although there was so much grease in there, it was hard to see anything. I then thought that the excess lube might be the culprit, but I thought wrong. The motor runs freely and the drive shaft appears okay.

To my untrained eye, it doesn't seem that any teeth are broken. Any suggestions?

I use the switcher on the Beer Line and there are beau coup thirsty folks anxiously awaiting a positive outcome.

Many thanks,

Jim