So I got curious(er) did a little more digging on my SD45, which was the next one up for a new tach tape.

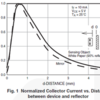

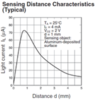

The tach sensor has some logic built in, probably similar in principle to the one I described here, which I used in my Arduino turnout project. It looks for a change in reflectivity of the tach tape, and outputs basically a yes/no signal to the processor. Unlike the one I mentioned, however, there seems to be one key difference with this sensor - it requires an active transition from say, black to white, in order to output anything. So if I spin the flywheel slowly by hand, the output of the sensor never goes high, even as both black and white stripes pass under it. If I spin it faster, then I see the output going high and low as you would expect. I think this plays into the minimum stripe size, as you'll see below.

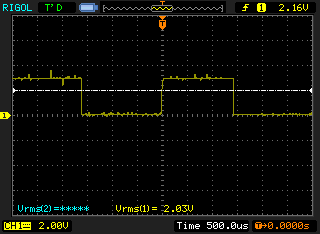

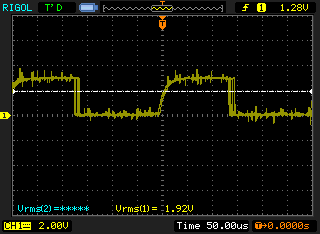

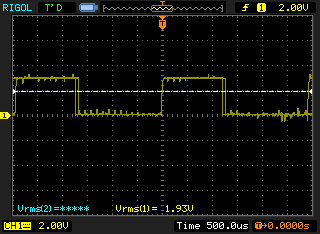

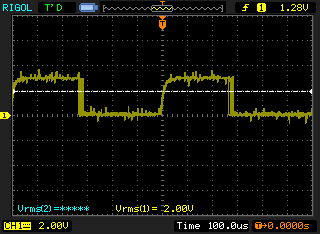

Here is the response of the sensor at speed steps 5, 10, 50, and 100 with the stock stripes:

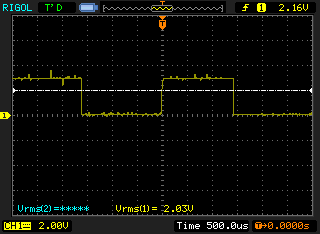

A couple points to note. The period of the pulses corresponds linearly to the speed setting. That is, for example, at speed 10, the period is right about at 3ms. At speed 100, the period is 300us. So to the processor, a 3ms period is speed 10. It doesn't matter what the actual width of the strip is, which is why I was curious as to why there was a minimum limit.

Also, the curved rise in the signal is present at all speeds, it's just not evident in the speed 5 and 10 screenshots. So it's not simply a case of the signal degrading at higher speeds.

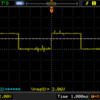

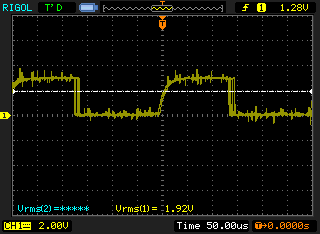

Here are speed steps 10 and 100 with the 0.050" stripe tape:

So far, so good. Looks exactly like the shots with the stock stripes.

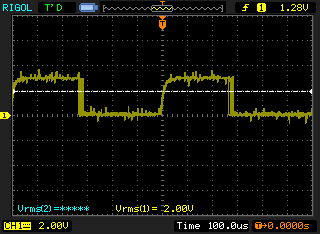

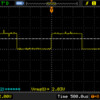

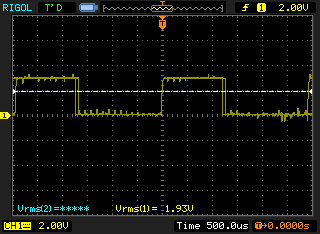

Here's a couple screenies with the 0.030" tape:

In these shots, you can see that, although the period is generally the same as with the stock and 0.050" tapes, there is quite a bit of variability in the response. I think we are right near the limit of the sensor, which is subjectively consistent with the results I saw on the Also - it ran, but just.

Then I tried the 0.025" stripe tape, and got - nothing! No output from the sensor at all. Moving it by hand as slowly as I could still produced no output. I think what is happening is that the stripes at that point get close enough together that the sensor is no longer able to discern a transition, at any speed, and so there is no output. So that's why 0.030" works, and then, suddenly, 0.025" doesn't work at all.

So it looks like even if the stripes are really sharp, at around 0.025" width, the sensor is not able to identify discrete transitions, and generates no output.