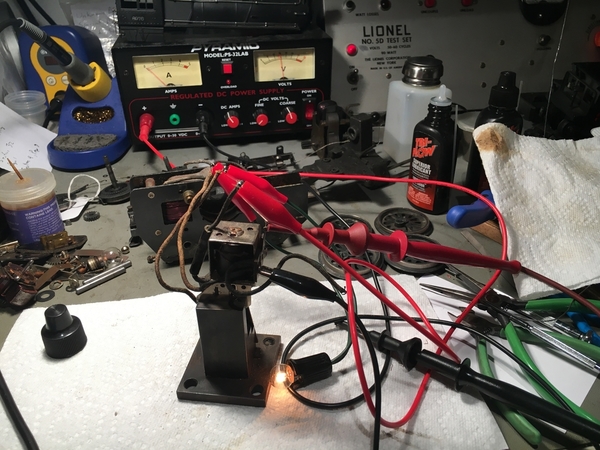

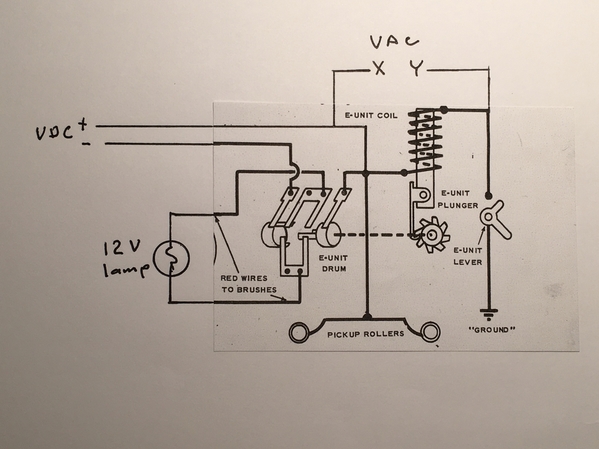

Last night I had an e-unit I wanted to test. I had rinsed it out with contact cleaner and sprayed Deoxit D5 on the contacts. I wanted to be sure it worked before installing it, but did not want to take it apart unless I had to. I came up with a simple way to test all the contact operations. On the four finger contact plate the outside contacts are the field wire and the center rail power wire. This e-unit is from a loco with a permanently grounded field. The center wire is a brush wire. In the two finger contact plate the single wire is the other brush.

I put a light bulb across the two brush wires and connected my DC power supply to the field and center rail wires on the e-unit. Then I used me 5D tester to supply AC power to the coil to cycle the e-unit. It worked perfectly. Every time I cycled the e-unit the lamp would either turn on or off. Of corse the polarity on the lamp was reversing every time it turned on, which I could not see. But I cannot phantom a e-unit being so screwed up that it would not reverse polarity every other cycle.