Thanks JohnActon for your reply.

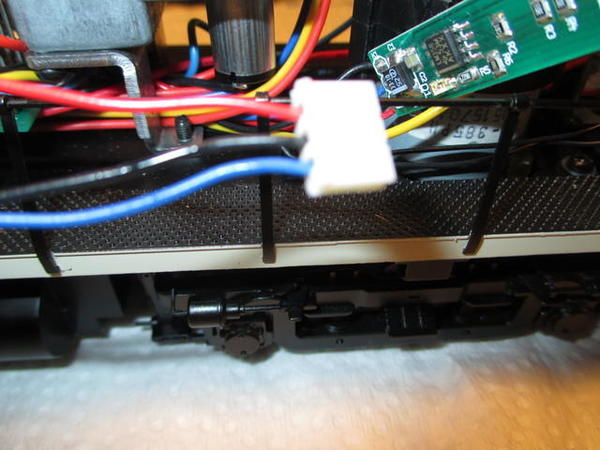

Here is an update to where I am at on this.

The switch on the frame Conv-Cruise ON/OFF does not seem to turn the cruise off in Command. I suspect it is bypassed in Command Mode.

I was able to use the sequence in the manual and turn off the cruise in Command. This worked, cured my issues and the engine ran fine - but without cruise. It actually runs quite nicely in non-cruise mode. Cancel the command and put the engine back in cruise and the crazy behaviours return.

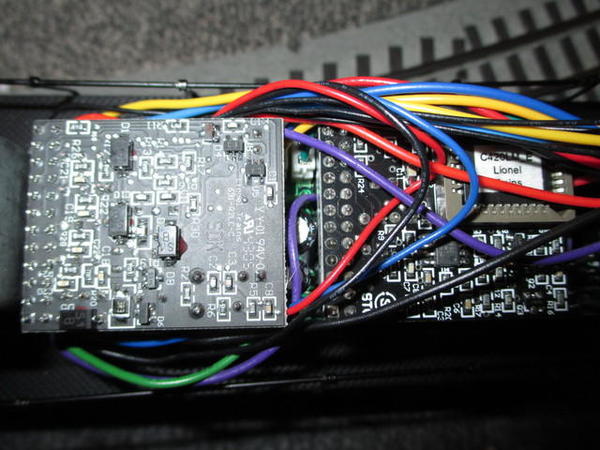

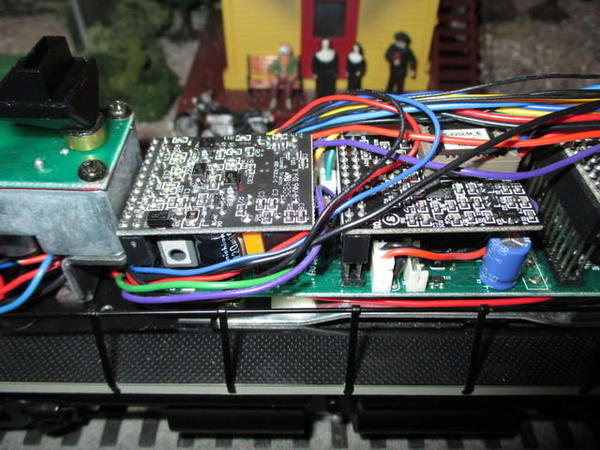

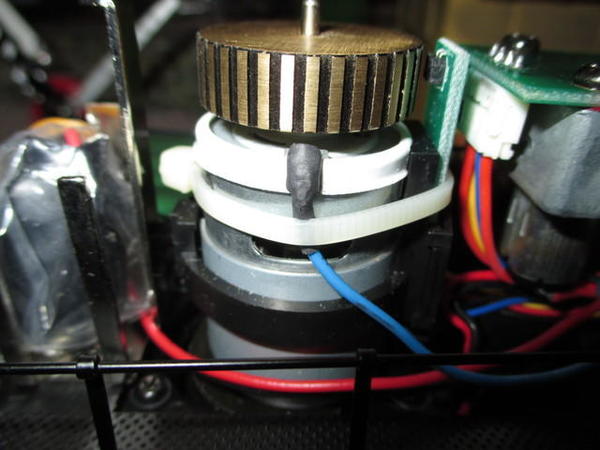

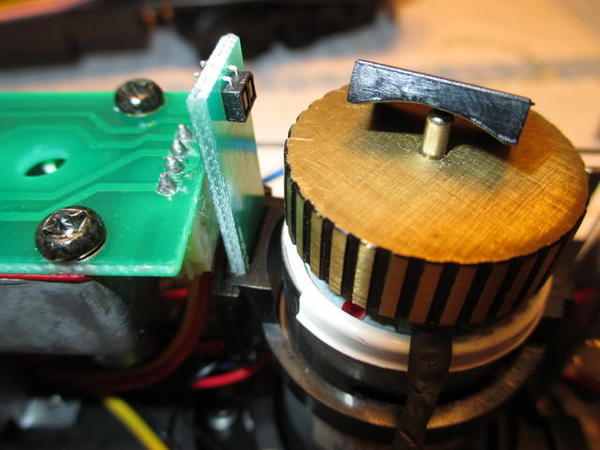

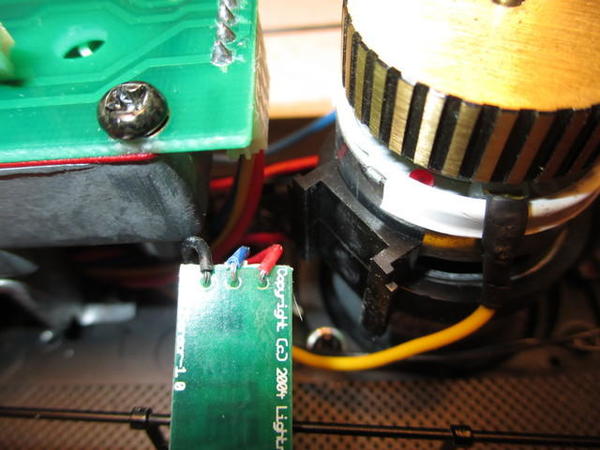

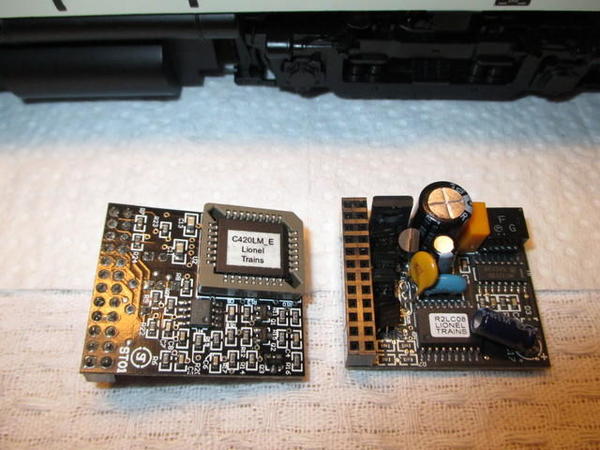

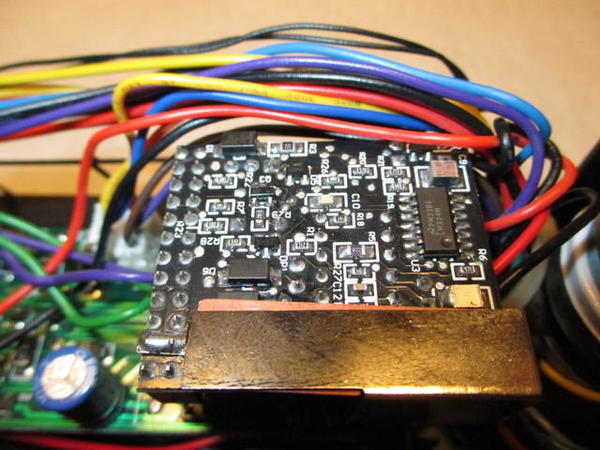

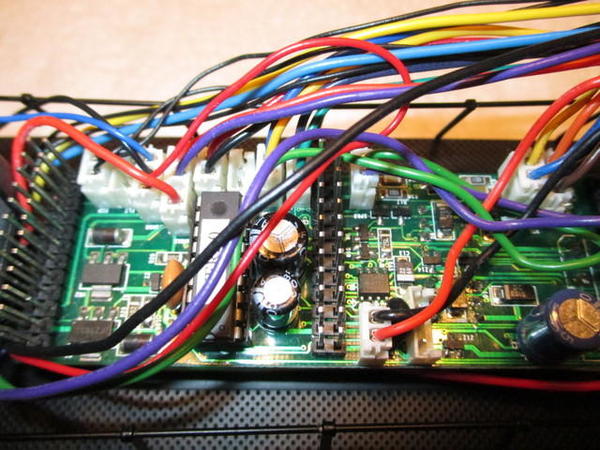

I "borrowed" a sensor board from another engine and the engine in question is now performing as it should in cruise mode - Command. So....the problem was the sensor board...defective somehow.

Now I need to buy a sensor board if anyone has one to sell !

You can set the cruise to 32 or 128 speed steps. Control is very good but I find ERR just a bit better.

My soldering iron has been long overdue for replacement. Your information and GR John's suggestion of the HAKKO put me over the top and I just ordered a HAKKO FX888d from Canada at a good price (I am in Canada).

Dave