Hey all! Young, fairly new railroader with some dumb questions here. Since I’m waiting until I get a house before setting up my layout, I occasionally bring out the trains to lube them and top-off the smoke fluid as some preventative maintenance to prevent future issues for when they come out for good (and the itch to run the trains starts eating away at me until I give in).

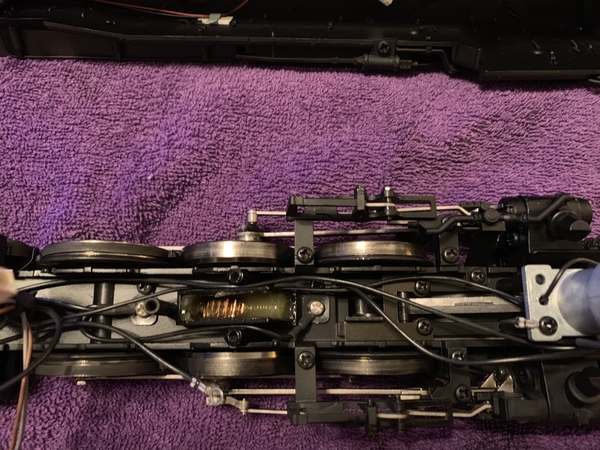

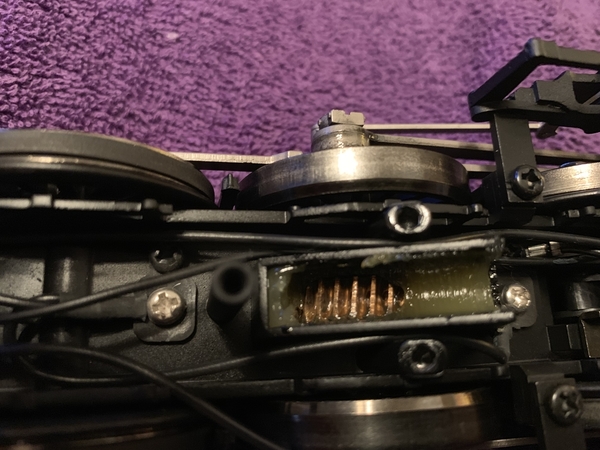

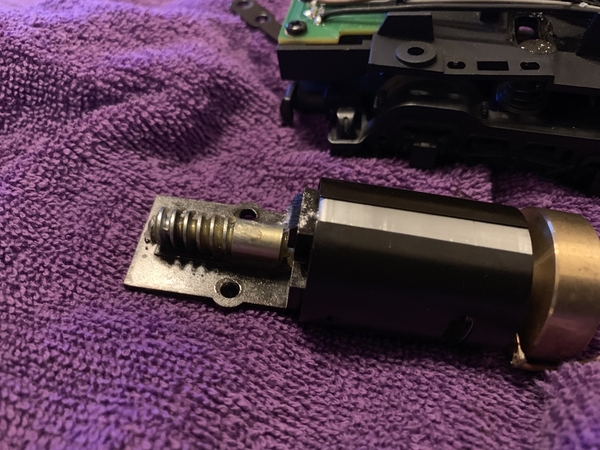

I went to run my K-Line NYC J1e Hudson and I’m having an issue where the loco acts as if it is binding. It’ll make 1 or 2 full revolutions before it “binds up” in either forward or reverse. None of the moving parts visible at the piston and wheels seem to be the culprit. I’ve been attempting to find a manual for the loco online but haven’t been able to find much info or a disassembly guide on this locomotive (K3270-5344W) and I’m just curious if anyone has any info for disassembly.

I’m usually fairly good with fixing things but I don’t want to screw anything up severely on the locomotive by just tearing into it and hoping for the best. Im going to assume something is wrong internally or possibly the motor may be acting up. If anyone has any info on the best way to go about this it would be greatly appreciated! Or possibly if someone does have a manual with a breakdown of the loco that would also be greatly appreciated! Thanks and sorry for the dumb questions. Like I said I’m fairly new to this still and don’t want to break anything by blindly tearing into the locomotive. Thanks for any help!