The 22" turntable on my layout is a tad too short. I am sure prototype railroads often had a same problem, a table a little too short. With the ingenuity that marked railroads (especially poorer ones), I would not be surprised if some found a way to extend the tables themselves without enlarging the pit. Has anyone out there come across any pictures of other solutions that might give me ideas?

Replies sorted oldest to newest

RJR posted:The 22" turntable on my layout is a tad too short. I am sure prototype railroads often had a same problem, a table a little too short. With the ingenuity that marked railroads (especially poorer ones), I would not be surprised if some found a way to extend the tables themselves without enlarging the pit. Has anyone out there come across any pictures of other solutions that might give me ideas?

Yes, there are photos "out there" of how some railroads added a portable, raised-up extension in order to raise up the rear of the tender. I've seen photos of how both the PRR was able to turn the leased Santa Fe 5020 class 2-10-4s at a location in Ohio, plus the UP at North Platte, Nebraska when a 4000 class 4-8-8-4 occasionally operated east of Cheyenne.

I've see them, HW. I was wondering if any RRs would have extended the table deck past the endges of the pit, using bridgework or some other means to support thge wight.

The OH location was Columbus, when the Santa Fe engines were leased for PRR Sandusky line service in 1956. The UP North Platte table would not accomodate 3900-series 4-6-6-4's. A couple of steel wedges were placed on the end of the table, lifting the the last two axles of the 4-10-0 tender. Wood blocks were placed beneath each axle to make them self-supporting, allowing the wheels to clear the rails of the house leads. Ingenious! The suspended tender protruded 6-8 feet beyond the end of the table.

I ran into the same situation. I extended the deck and rails 1" on each end. (actually I replaced them with longer 24"rails). So the deck overhangs the turntable pit and the deck passes over the "earth" by about 1/16" as the deck rotates. Each track leading to the turntableble was cut back 1". I have never had anyone notice this until I point it out. Not ideal but better than 22".

RJR posted:I've see them, HW. I was wondering if any RRs would have extended the table deck past the endges of the pit, using bridgework or some other means to support thge wight.

Personally, I've never heard of that. I can not imagine how such an "extension" would last very long, what with the extreme weight of a steam engine & tender passing over it.

HW, True, but no telling that a short line w/ light locos, or an interurban line, might have added some structural support adequate for what locos they had.

Admittedly, I'm groping for a prototype. But I'm going to go the Astarr route as part of a Bowser rebuild. I shan't clutter the Real Trains forum with layout turntable discussion.

Thanks, RJR

Astarr: Could you please take a picture of your T T and post it ? Thanks, Art

Why not just use the Union Pacific solution?

As hotwater said, this was prr’s solution to the long leased Sante fe units. Found this on a post from 2015 here in a google search

Attachments

Mark, you'll notice that the PRR solution cannot be used to turn a loco--only put it onto another track

RJR posted:Mark, you'll notice that the PRR solution cannot be used to turn a loco--only put it onto another track

Nope. The PRR could turn one of those Santa Fe 2-10-4s 180 degrees, so as to depart the servicing facility.

How could they do that? Didn't that "ramp" limit access to only the other end of the TT? Or did it go off onto another track and then bypass the TT?

RJR posted:How could they do that? Didn't that "ramp" limit access to only the other end of the TT? Or did it go off onto another track and then bypass the TT?

Look at that "ramp extension" closely. It is raised enough to clear the rails as the turntable moves through-out its rotation.

Hot Water posted:RJR posted:How could they do that? Didn't that "ramp" limit access to only the other end of the TT? Or did it go off onto another track and then bypass the TT?

Look at that "ramp extension" closely. It is raised enough to clear the rails as the turntable moves through-out its rotation.

Just to refresh people's memories:

With the extensions, the Pennsy could spin those Santa Fe brutes to their hearts content.

Rusty

Attachments

True, but could the loco & tender exit the TT from the ramp end? If not, while loco could be spun, or could go into a stall, it could not be turned to go back on the main in the other direction. Loco could not be turned without having access to another track that by-passed the TT.

Example: from a lead track eastbound loco enters TT tender first, the pilot facing west. Rear of tender is on ramp. Loco can't leave TT tender first. But, loco can be turned so pilot is facing east, and it can go onto another EB track. Then reverse, go through a switch onto a track that by passes TT and connects to lead track at another switch west of the TT.

Correct?

If the extension is only on one end of the TT, the TT can be turned to point in any direction they want. They may have to back the engine onto it or run it forward, but there's no reason it can't be done, even if the front end of the engine had to ride onto the extension. Plus, the extension may be removable from one end to the other simply by unbolting them.

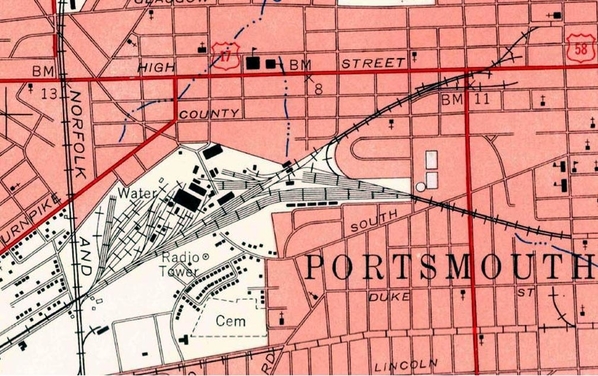

For the longest time I couldn't figure out how Seaboard ran their 110' long 2-6-6-4 engines into Portsmouth, being they only had a 68' TT, then I found a map that showed they had a Wye:

But I don't see the TT or roundhouse and transfer table they also used:

Never heard mention of a TT extension used by SAL, but I need to check with the historical society to make sure.

Attachments

Well, those photos ask more questions than they answer! Such as, how labor intensive were they to install? Were they automated or permanent? Could it hold the head end of the locomotive?

Bob, please describe to me how one turns a loco on a single ended TT, so it can proceed heading in direction from whence it came.

RJR posted:Bob, please describe to me how one turns a loco on a single ended TT, so it can proceed heading in direction from whence it came.

Simple. The loco enters the turntable from say, the east. The turntable rotates 180 degrees, and what do you know, the loco is now headed west! Can't be more simple. That is exactly how virtually every steam locomotive servicing facility in the world works.

HW, you're missing the point. It can't go off because the ramp is there. If it entered the turntable with the tender leading (a necessity because of the ramp), to go back whence it came, it must leave with the pilot leading. So the loco is facing in the same direction.

Hot Water posted:RJR posted:Bob, please describe to me how one turns a loco on a single ended TT, so it can proceed heading in direction from whence it came.

Simple. The loco enters the turntable from say, the east. The turntable rotates 180 degrees, and what do you know, the loco is now headed west! Can't be more simple. That is exactly how virtually every steam locomotive servicing facility in the world works.

I think you aren't taking into account the key words here "single ended". So, it's not going to work.

That engine had to back onto that table tender first. If you spin it, in order to head back in the other direction, there is no way it is going to back off that ramp. I think that is the point RJR is trying to make.

As I said earlier, this photo asks more questions than it answers.

RJR posted:Bob, please describe to me how one turns a loco on a single ended TT, so it can proceed heading in direction from whence it came.

I don't think the extension was necessarily put on first. Pull on, raise the tender by jacks, insert wedge system, lower tender, spin as needed.

My impression is a big loco on the extension would be pushing your luck far more and would be avoided.

It seems to me I recall one table's control house or some other obstacle was in the way of a total spin with an extension. They needed to pull a multipoint turn around, parking on a certain stub or two, and turning the table 180 and moving the extention for a reloading to continue to the next leg of the manuver.

Adriatic posted:RJR posted:Bob, please describe to me how one turns a loco on a single ended TT, so it can proceed heading in direction from whence it came.

I don't think the extension was necessarily put on first. Pull on, raise the tender by jacks, insert wedge system, lower tender, spin as needed.

Not quite. There are no jacks in solved, as that would take way too much time and too many men. The loco is simply moved onto the turntable in forward, and slightly off the table at the front, in order to clear the quick installation of the "jack-up bridge". The loco is then reversed and backs the tender up onto the "jack-up bridge", until the front wheels of the loco clear that end of the table. Then the turntable is rotated 180 degrees, and the loco is either moved forward off the table, or moved forward enough in order to remove the "jack-up bridge".

My impression is a big loco on the extension would be pushing your luck far more and would be avoided.

Well, the photo shows how the PRR turned the leased Santa Fe huge 2-10-4s, and the UP used a similar arrangement to turn a 4000 class 4-8-8-4 at North Platte, Nebraska.

It seems to me I recall one table's control house or some other obstacle was in the way of a total spin with an extension.

Must admit that I've never see a turntable with an end mounted operators house, where one of those "jack-up bridges" wouldn't fit on the rails.

They needed to pull a multipoint turn around, parking on a certain stub or two, and turning the table 180 and moving the extention for a reloading to continue to the next leg of the manuver.

What?

" The loco is simply moved onto the turntable in forward, and slightly off the table at the front, in order to clear the quick installation of the "jack-up bridge". The loco is then reversed and backs the tender up onto the "jack-up bridge", until the front wheels of the loco clear that end of the table. Then the turntable is rotated 180 degrees, and the loco is either moved forward off the table, or moved forward enough in order to remove the "jack-up bridge"."

Now that makes sense. Thanks.

Good gosh.....the large locomotive backs it's tender on the extension, allowing the front of the engine to be turned anywhere on a full 360 degree circle, and to exit. Onto a service track or into a roundhouse stall. The hostler or TT operator only had to point the table for the locomotive to back on.

Now the discussion can move on to whether it would require a full or empty tender so as to balance on the table !

One of the references on the internet says oil and water have to be low, to cut weight on the extension.

RJR posted:One of the references on the internet says oil and water have to be low, to cut weight on the extension.

Correct. Plus, those larger turntables, i.e. 90 feet and longer, do NOT have to have the locomotive in a "balanced" position, as did the much earlier/older turntables.

Andrew's picture shows some rail hardware in the foreground, so suspect workers had to occasionally adjust the location of the risers from one side of the table, to the other. If a locomotive arrived nose first to the table, it could not back onto the table.

mark s posted:Andrew's picture shows some rail hardware in the foreground, so suspect workers had to occasionally adjust the location of the risers from one side of the table, to the other. If a locomotive arrived nose first to the table, it could not back onto the table.

No, but it would continue forward onto the opposite mating track, in order for the tender to clear its end of the table, so that the "jack-up bridge" components could be installed. The the loco would reverse, and back the rear tender truck up onto the ramp, until the front wheels of the locomotive were back in the table and in the clear.

HW, I couldn't find the post to fully answer the "What?". At first I couldn't understand it either. I just recall that someone expanded on the puzzle before I understood and I don't recall exactly what the method was. It was convoluted. I actually hoped you'd know. (maybe the table didn't 360° ?)

Going over it in my head, they may have had to move the extension to do a 3 point, but without more facts, it IS a failed example anyhow. ("my bad")

Good grief! The easiest way is to have a turntable that has leads coming into it from both directions. You back the loco & tender onto the table with the rear tender wheels up on the ramp. Then you rotate the turntable approx 180 degrees to line up with the turntable lead coming from the other direction. Then you move the loco and tender forward off the table. Vwallah! Its been turned. Even our old BNSF/BN/CB&Q roundhouse at Sheridan WY had one roundhouse stall track that went THROUGH the back wall of the roundhouse opposite the other 2 turntable leads which would have allowed turning a long loco like this. Sheridan Wyoming turntable with opposing leads

Another way to turn a too-long loco utilizing one of those ramps is to simply have a roundhouse stall track (or a 20ft long stub track) that lines up with the turntable lead track. In other words you could run a loco straight across the turntable into a stall or partially onto the stub track. Once the front of the loco is far enough off the far side of the turntable you place the ramp on the turntable behind the tender. Then you back the the tender up onto the ramp until the front loco wheels are on the turntable. Then you rotate the turntable 180 degrees and run the loco & tender off the table onto the lead. Vwalah, the loco has been turned.

If the loco needing turning is backing onto the table, you place the ramp at the far end of the table and back the tender onto the ramp until the loco's front wheels are on the turntable. Then you rotate the table 180 degrees. Now you move the loco & tender forward about 20 feet onto the stall track or the stub track until the tender wheels are off the ramp and then remove the ramp. Now back the loco & tender straight back across the turntable onto the turntable lead and Vwalah, you've turn the loco.

You could add one inch of rail to each end of the turntable rotating bridge. This would make the track on the bridge two inches longer than it original length but the bridge could not yet be rotated.

Then cut one inch of rail off of all the stall tracks and the rail approaching the bridge to allow the extra inch of rail over hanging the bridge to be rotated.

Edit: 9-30-2021 10am CDT Here are some answers to later questions on the strength of the 1 inch section.

The one inch of track rail would most likely support only one wheel of coal tender 4 or 6 wheel truck or the "none engine weight supporting" front wheels of a steam locomotive. There would only be 1 inch of unsupported track and most truck and wheels load is supported on more than that length.

Also a 2 inch length of finish nails (with head cut off) could be inserted in the the two outside rails that expend out 1" to strengthen the rails. Many two inch finish nails will fit tightly inside 027 track but other sizes may be needed for O gauge track. Coat hanger wire could be used but finish nails are stronger.

Charlie

@Choo Choo Charlie posted:You could add one inch of rail to each end of the turntable rotating bridge. This would make the track on the bridge two inches longer than it original length but the bridge could not yet be rotated.

Then cut one inch of rail off of all the stall tracks and the rail approaching the bridge to allow the extra inch of rail over hanging the bridge to be rotated.

Charlie

Except,,,,,,,,,,as soon as a locomotive moved onto the turntable track, that one inch of rail would break right off, since it would be unsupported by the turntable bridge structure.

True, but you might be able to stiffen it enough by soldering the connection or adding some bracing across the connection or both and, at 22"-24", its not carrying the heaviest locomotives.

@Choo Choo Charlie posted:You could add one inch of rail to each end of the turntable rotating bridge. This would make the track on the bridge two inches longer than it original length but the bridge could not yet be rotated.

Then cut one inch of rail off of all the stall tracks and the rail approaching the bridge to allow the extra inch of rail over hanging the bridge to be rotated.

Charlie

@Hot Water posted:Except,,,,,,,,,,as soon as a locomotive moved onto the turntable track, that one inch of rail would break right off, since it would be unsupported by the turntable bridge structure.

Also in the situations described previously, the UP and Santa Fe locomotives needed much more than 2" of extra turntable track.

Rusty

@Richie C. posted:True, but you might be able to stiffen it enough by soldering the connection or adding some bracing across the connection or both and, at 22"-24", its not carrying the heaviest locomotives.

Please note that this discussion is on the Real Trains Forum, thus "soldering the connection" would NEVER work on steel railroad rails! Also, what does "at 22"-24", its not carrying the heaviest locomotives" have to do with this???

@Hot Water posted:Please note that this discussion is on the Real Trains Forum, thus "soldering the connection" would NEVER work on steel railroad rails! Also, what does "at 22"-24", its not carrying the heaviest locomotives" have to do with this???

I did not select the Forum on which the original topic was posted and suspect it was posted in error. The original post referenced a model train "layout" - a term not generally associated with a "Real Train". The original post also referenced a 22" turntable, which is probably too short for a "Real Train". It also requested information or pictures of real train situations that would help the poster find a solution for extending the turntable on his model layout.

Finally, it was you who posted, "Except,,,,,,,,,,as soon as a locomotive moved onto the turntable track, that one inch of rail would break right off, since it would be unsupported by the turntable bridge structure" to which I was simply responding and offering a potential solution.

So, please tell me, what does your comment about "one inch of rail" have to do with real trains ?