I had/have dreams of a revival of that layout. I've been too physically limited to clean the space properly though. There are other issues too, like stairs. Down there, I don't think I'd do as much, nor as often. Benchwork and wiring is still here though; about 15' or 18'x30' or 32'; I forget exactly but has been pulling "crap shelf" duty for decades.

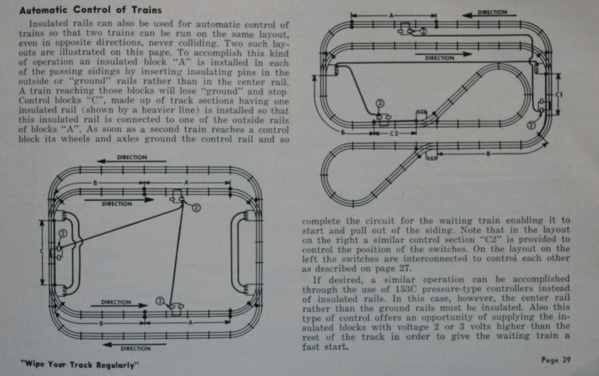

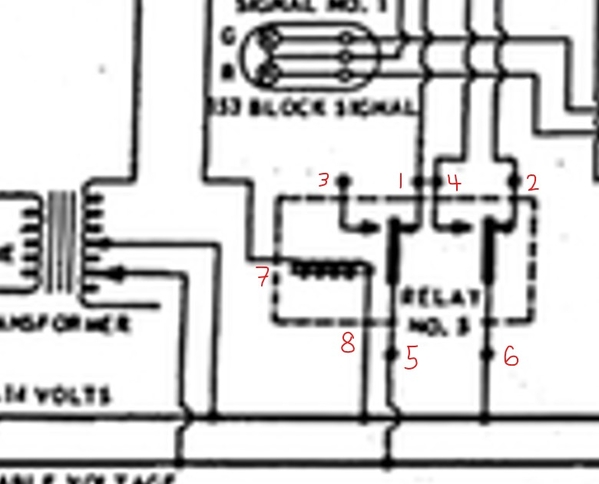

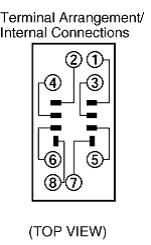

I actually use a similar block set up on a ceiling shelf, but 2 loops that share a main along one wall. The main must be clear of train #1 before either loop releases train #2. My #1 actually as to fully clear the main before #2 triggers the anti derail at the mains entrance as the turnout's wiring at both ends of the main are tied together so the point dirrections are synced.

I had an assistant that saw "reds as greys". Never an accident but we began to using more number tags as a rule for him.

I usually call it a "track switch" to distinguish it from an electrical switch. The word "turnout" is really the proper term, but you almost never see it used in Lionel's catalogs and other literature.

I grew up calling them "switch tracks" myself, Gramps used that to differentiate from a electrical switch. Our retired Big Cheese Rich "set me straight one" day. Gramps tended to be pretty tight on prototypical use of terms; I still wonder if the use of "switch tracks" wasn't one of those regional mining or logging RR terms from somewhere up north or in Canada.

I don't always adhere to using it, but appreciated the correction more than some might expect; at least I know what's actually used on the job now

I don't use command. I only have had a few that support it and or electric sounds. I grew up without the sound and to be honest, chuff got old and distracts my ears from the real mechanicals. The soothing rythm of the cyct tender is the one sound that doesn't distract or annoy me. I think it's because it so closely resembles the steady rythm of operating pumps off the post war oil towers; an ever present accessory on Gramps layouts.

So, two trains on one loop can be done, two loops connected and two trains also.... Command has lots of aspects to learn about. I'd encourage you to sample them, but not to act in haste. Be aware electronics are fickle too. The command game is more work, make sure your happy with the outcome of these types of efforts. I'm kinda lucky I'm "easily ammused" and don't feel I "need" it. (it kinda reminds me of work too. I didn't love my job THAT much  )

)

Know your running style before you commit.( I'm a looper; my indoor campfire; I shoud have spent less effort on sidings and gone for double reversing loops.)

The options today are numerous. It's often just easiest to read a highly detailed *"foolproof" explanation* or see a diagram of your intentions, needs, etc. and go from there. (It's still a little vague on loop count, etc.) ( * "to teach well, a teacher must assume the student knows nothing"....{Plato?})

There is a Windows software program called SCARM(simple computer aided railway....manger? (I forget the M) ; google pulls it up. I think they still offer a free trial version (50pc limit). (author Mixey posts here at times too) Make a sketch with it. (include a jpg "screen shot" and the scarm file. Some folks don't run windows, but can still see and paint on a jpg., those with scarm can change things with the program and include a new scarm file for review.)

Making software layouts can be time killing fun as well as a prudent planner. Railroad Trak & Anyrail are two others, less learning curve, but scarm is worth the effort for the infinite axis, zoomable, 3d view.

This sketch begot this layout, using the three old Lionel track types; O-27,O, Super O. (4.5x9)