I am still at the playing on paper stage and considering a switch to Ross track.

But I am having difficulty doing even some very basic track planning.

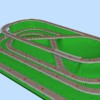

Example is attached. I can't close the passing siding!

Ross make almost no partial curves at all and no flex track. I can't find any sections that would permit this siding to close. Not in the Ross catalog and not in the Anyrail track planning Ross Track library.

This can't be right. I am doing something wrong.