Originally Posted by sinclair:

And as an aside, don't get a Makerbot, get something else like a Stratasys.

Or more realistically, an SLA type printer like the Formlab or B9 Creator. These are also desktop consumerist printers, but use cured resin as opposed to fused filament (like the Makerbot) for the material. Generally, SLA printers are going to offer higher resolutions with thinner print layers.

I think the important distinction with 3d printing is between short run/prototyping versus production. Can printers produce just about anything you can imagine? Absolutely. Can they produce 5000 pieces in a timely, affordable manner? Absolutely not. So yes, 3d printing could work well for creating masters, albeit requiring post printing finishing work. And no, companies like Lionel cannot pragmatically use the technology to manufacture high volume production runs. As usual, the caveat applies that current technology has certain limitations and that technology will invariable improve and cost less in the future.

The four issues with 3d printing for production at the moment are resolution, speed, cost of materials, and what I'll call value. The value component is simply the acknowledgement that much better results could be gained if the very best (and therefor expensive) printers could be used. But for what most of us could afford, and even for most manufacturers, the first three issues are the prevalent ones.

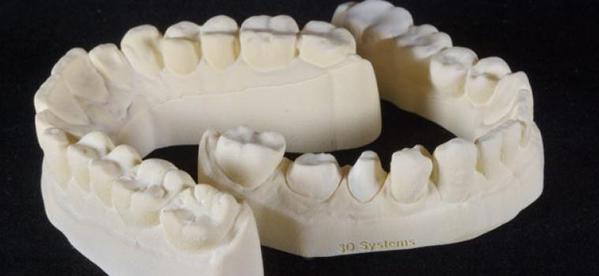

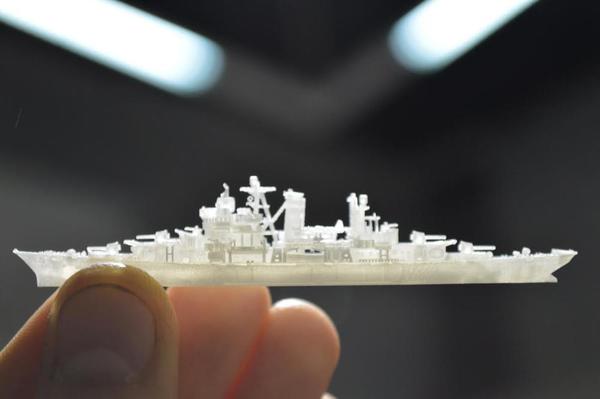

Here is a bolster for a modern 100 ton roller bearing freight car truck. It is printed at 1:48 scale on a high quality Objet printer. Even using the Objet printer, the final product would still require some finishing work to clean up the surface. Also, given the small size, the model is quite fragile. I've damaged parts of it while trying to remove support material from the inside of the casting. This part was printed by the same 3d printer hub that printed the tiny naval boat shown in Erik's post above. Note that not all support material has been removed from the inside, but the outside of the casting is the bare plastic.

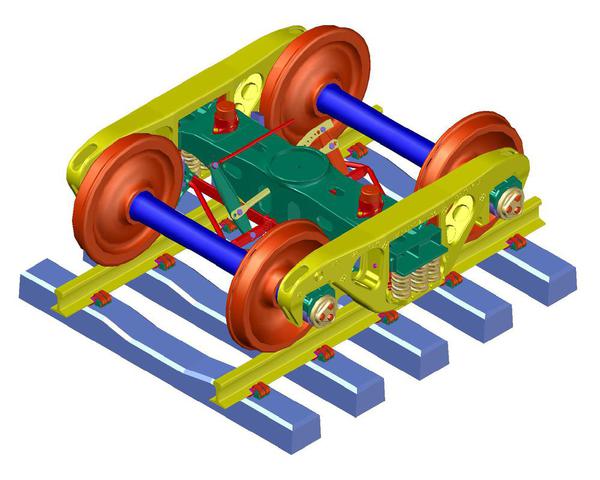

I've posted this next model elsewhere here on the forum. It's printed at 1:10 actual size on Stratasys 1200 and 250 FDM printers. Again, the resolution is okay but not finish quality. Worse yet from a production standpoint, there are probably 150 to 200 hours of actual print time to create the parts for what you see. I've since added more detail to the castings as well as full brake rigging that will take even more time to print.

I hope this helps give a sense of what is possible, but also what some of the limitations are. Better printers produce better results, but at a significantly higher price. Practically speaking, printers have limited use currently in production, but great value in the prototyping process.

If anybody has any questions, feel free to ask. I probably know just about enough to be dangerous!

Jim