Darlander, Look at you go over there! I thought I was the only one that kept stuff from the trash for modeling! LOL Have a great time with your grandson!

Paul the roof looks great! You have gone this far why not add some floors and put some people in the windows! LOL Just kidding, looks great!

Ralph, its always nice to have a nice easy fix every now and then! I weighed all my cars a few years ago, and will do the same thing before going on my future layout!

Mark I didn't know you had that many diesel engines! LOL

BRYAN, The ball field looks just amazing! Congrats for having another project finished! GREAT WORK and LOVE IT!

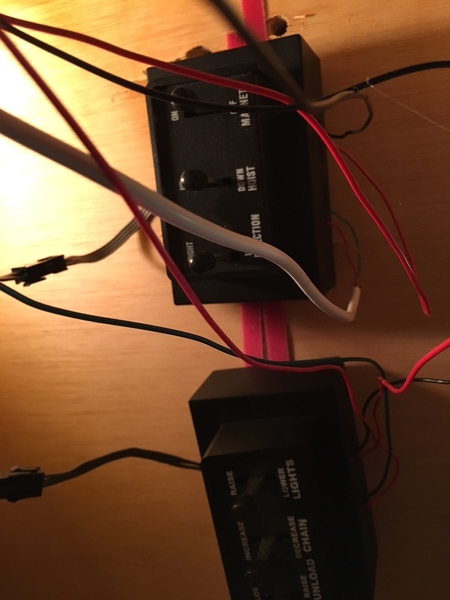

I just worked alittle on the train room!

Mike, I have two Premier Western Maryland H9s, one Premier B&O Atlantic, and one Premier B&O 0-6-0 switcher. Then I have a B&O F7 set in the blue/gray scheme, and a B&O F3 set custom painted in the solid dark blue. Also I have Western Maryland F3 set, two WM BL2s, a WM RSD5, They are all Premier or RailKing Scale. That doesn't mention my Christmas engines, all traditional sized steamers. I prefer steam, but Premier steam is costly for me even on the used market.

So the SD70ACE is really an oddball for me. I traded a Forum Member who has been looking for a Premier FA2 ABBA set for a long time, but didn't have the cash. I finally contacted him back about a trade. The ABBA set was just too long to look good in my small space, so I thought he should have it. I know if I tire of the SD70ACE, there are lots of folks right here in Western Pennsylvania who would like to have it. It is a really cool engine, but will look out of place in my 1950s era West Virginia layout. It may just stay on the Ceiling Central RR, which will accept any era.

![]()

![]()

![20180728_213816[1] 20180728_213816[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/12129987997660671/primaryPicture/true/filePointer/80551019478361064/fodoid/80551019478368390/imageType/SQUARE_THUMBNAIL/inlineImage/true/frame/FIRST/thumbnail.jpg)