It is clear that to power your track its 14 or 16 AWG wire. Not so clear is what AWG wire size to use for switches and accessories with your AIU. I have allot of 22 gauge audio signal wire. I would like to use it but I'm concerned it is too small. Any input?

Replies sorted oldest to newest

#22 is fine for accessories or switch power and control.

Ozzie's Son,

Make that 14 gauge stranded wire for best results, and I agree with Guns the 22 Gauge is fine for the accessories and the AIU.

PCRR/Dave

Hate to disagree with Brother John, but I'd say it depends on the accessory. If you're controlling an old #97 coal elevator, you need at least 18. For NJIntl switch machines or postwar 022 switches, probably the same. DZ1000 switch machines might work ok with #22. An LED lamp, #22 would be more than adequate. Best way to know is set one up on the workbench with leads as long as you'd expect on the layout.

Due to small size of the terminals, it may be necessary to use a short lead, a few inches, of thinner wire.

Actually, it all depends what the AIU is switching on and off.

For switch tracks (wired to SW ports) that use very little power to momentarily run a motor or activate a coil magnet, 22 gauge is typically fine.

However, anything wired an to ACC port that runs for a while and draws higher amps, such as many older Lionel postwar accessories (164 and 364 log loaders, coal elevators, etc.) may require something a bit larger, such as 18 gauge.

Barry,

I did forget that I had to use 18 for my switches back in those days, the 22 was definitely to light for them.

PCRR/Dave

Thank you everyone!

I appreciate your input and quick responses!

Sorry guys, but unless the accessory is in the other room, I have to disagree that you need 18ga wire.

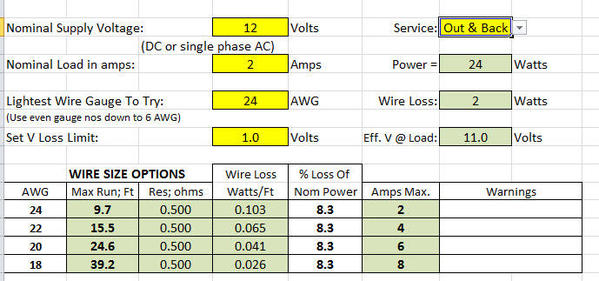

Let's assume 2 amps for the accessory, I know the O22 switch won't have any problem with #22, I've wired them with 30 feet of wire with no issues at all. The #364 log loader uses just over an amp in operation, so I don't see an issue there either. In truth, very few accessories will continuously draw in excess of 2 amps, so let's use that as our benchmark. Using the excellent wire gauge calculation spreadsheet that Rod Stewart created a while back, let's check...

Looks like for 2 amps and assuming a maximum of a 1V allowable drop, I can have a 15 foot run out and back and run the accessory fine. Obviously, for lower currents, I can run a longer run.

There is no issue with #22 carrying the load, and since most accessories tend to run best on a fixed voltage, adjusting the incoming voltage slightly for a longer run would not be a factor.

There seems to be a trend to go with the bigger is better idea for all wiring, in truth that isn't always the case. I select the wire size needed, there's no reason to go with the bulk and expense of #18 wire for a vast majority of the accessory wiring on a layout. It obviously won't hurt anything, but it's certainly not a requirement for safety or performance.

Attachments

Guns,

If I remember right, until I replaced the 022 switches light bulbs with LED's I had to keep the handle of the old ZW pretty far up, to run all the switches correctly, in reality, the 22 wire was not brought on until I used the LED's in the controllers and the individual switches.

This was especially true when I started to use all 711/072 Lionel switches and did away with the 022's, the big old switches really drew some power to operate correctly.

One of the big reasons for my purchase of the Legacy Cab2 was because of the invention of FT Command Control low voltage switches, controlled by the Cab2 remote control, that can now run completely wireless off track voltage. The ability to go low voltage wireless with FT CC switches is big time engineering, eliminating all wiring between the AIU & Switches. If you want to wire the accessories to the AIU to be controlled by the DCS remote control the 022 wire is more than adequate.

PCRR/Dave

Dave, that's voltage and not current that was the difference. I've found that a lot of older 022 switches, even after a "tune-up" still require a minimum of 15-16 volts to switch 100% all the time.

The resistance of the 711 switch coils is the same as the older 022 switch coils, they should require the same current.

I tried this little experiment. An 022 switch on the bench, connect the power 16VAC, and trigger the operation but hold the lamp housing to have continuous power to the coil. You'll measure right around 2 amps. Since in actual operation this is only present for a fraction of a second, it's not an issue.

Yes, if you daisy-chain the power to a bunch of switches, the lamps start to add up, that's a different scenario, and then you'd be talking more current and voltage drop.

No point in arguing about accessory gauge. Connect your #97 coal elevator or equivalent with22 wire. Clip an ac voltmeter across feed terminals. Activate the mini-pulmor motor and the chute solenoid and see what voltage is being shown on the meter. If it meets your standards, fine. If not, go to larger gauge. It's your layout and you can run it any way you wish.

RJR,

There is no argument going on, we are just talking engineering and reality of

operation. In fact as Guns indicated my old switches were daisy chained, drawing serious voltage. It was one of the reason I went to the LED lights. Ours discussion was about the wire required to get the job done correctly, and depending on the situation and number of switches with or without LED lights the situation changes and the man who started the thread got the information needed to make an informed decision for his own layout. It's one of the things that makes this OGR so great.

PCRR/Dave

Dave, I didn't use "argument" in the sense of a fight, but rather to refer to an animated discussion. Just like an "argument" at the Supreme Court is a gentlemanly presentation. Those old 022 switches drew a lot of power just sitting still, due to the bulbs, which Lionel said drew 5 watts each.

My test was with a bulb, though I confess I didn't have the second bulb load on it as I didn't have the control connected.

If you are daisy-chaining the power, then I could see using heavier wire, but I don't feel it's necessary for one switch.

Guns,

Man I had 11 sets of combined 022/711-072's on the 1st office layout, and with them old switches Daisy Chained and powered from an old 275 ZW, I had to use the LED's

to make everything work decently, I definitely needed the 18's. For just a few 022's with LED he should be fine with 22's. Scotty we need more power!

PCRR/Dave

I'd be careful to not overload the AIU if you need 18 gauge wire as each port is only rated for 4 amps. It might be a good idea to use a 4 amp fuse to protect it if you are drawing close to that much.![]()

An excellent point Joe! ![]() I forgot we were talking about the AIU ports, I got lost in the wire size discussion!

I forgot we were talking about the AIU ports, I got lost in the wire size discussion!

There are actually 2 related but distinct issues. One is the carrying capacity of the component. The other is the amount of voltage drop you are willing to accept for a given device over the length of wire to and from that device.

Yes, but the maximum of 4 amps gives you a ceiling.

Yes.

Gentlemen,

Barry's comment as to it all depends on the switches is right on the money, wire size always depends on usage. Guns was right about the 22 for most accessories and it would have no problem handling the new low voltage switches also, when you get into daisy chaining of old Lionel 022's & 711/072's with standard bulbs things change with the power being carried, even with replacing the old bulbs in the controllers and switches, I opted to replace the 22 wire with the 18, for safety sake, while running all the switches, and accessories from 2 different channels of an old 275 ZW transformer. It worked perfectly and I never had any trouble what so ever.

PCRR/Dave

Thanks again to everyone who posted.

Oddly enough while most of my layout is recent stock with Fastrack. My original sets from my dad were 3 Lionel sets from 1955 and I want to keep them running with the original transformer, track and accessories in a small 4 x8 section of the layout by them selves. So every contribution was valuable.

Use of #22 gauge wiring on all AIU outputs.

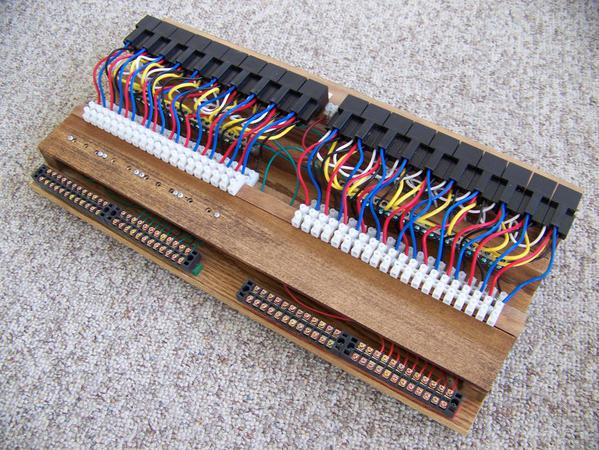

Since I set routes using my TIU/AIU combination as well as via a pushbutton panel I use separate 12VDC relays. In some instances I control up to 6 turnouts to set a route. Therefore I can use light gauge wiring for control of turnouts as well as power to "blocks" since the relay coils draw less than 1/4 A each. The relays are rated at a minimum of 15 amps.

All wiring to the AIU terminals is prewired to "numbered" terminals on separate terminal blocks.

AIU Relay Board Interface - Wiring to the relay board from the AIU is #22 gauge. All wiring is color coded. All relays plug into sockets which makes replacement very easy. The relays are heavy duty automotive types.

Attachments

Here is a photo of a complete TIU/AIU control system wiring system. All wiring from the control side is 22 gauge wire. All other wiring to the turnouts is 18 gauge. All wiring to "blocks" is 16 gauge.

All wiring is color coded. Not shown are a pushbutton turnout "route" control panel, a block control control panel and a separate "Dispatcher" panel.

This control system will also be adapted to wireless control using a Tablet when hardware and software interfaces become available. Meanwhile my "hardwired" panels will always be usable as is.

When the wireless system is complete this control system will permit control from the DCS (using the MTH remote or Tablet) and the separate hardwired control panels. My system presently includes independent control of Lionel TMCC engines via the DCS or TMCC controller as well.