Note click on photos for a larger view.

Your LionChief remote will break if you let lots of kids use it and are not able to keep control of them when in use. The speed control knob is easy to turn too far breaking the internal electrical control. Here is how to fix it in under an hour.

I have been doing model train displays for kids to run for many years at several shows a year. I think this is important to let families have a first-hand opportunity to see kid friendly model trains and try them out. It keeps interest up and builds our hobby with new families getting a chance to try what is on the market perhaps being interested enough to purchase a set.

I have always been concerned with handing kids the DCS or TMCC remote, or trying to hold it so they can only push a few buttons, but getting sticky fingers on them and occasionally having something break or the kids drop it. Expensive to replace or repair.

I am not keen on having kids around a 120 volt transformer to control the trains either. Too many wires they might try to get in to or could something go wrong with a transformer.

So I was thrilled when Lionel announced the LionChief remotes. Perfect kid friendly easy to understand and handle remotes. As soon as Thomas with the LionChief remote was released it became a main feature of my show display layout. First weekend we had it at a show the kids broke the control knob turning the dial too far around.

The problem with the LionChief remote is that there is about a 4-5 second delay from when you turn the speed control knob and the train moves. I understand this is advertised by Lionel as a safety feature so the kids cannot spin the knob back and forth breaking the engine, and adding a momentum feature. Try telling a 4 year old to wait till the train starts!! They are used to instant RC vehicles and video games that respond as soon as the control is moved. Waiting for a train to move when you turn a speed knob is difficult to get across to new users. Now if you have a remote at home and time to get a new user used to the delay that is not a problem, but at a train show where there will be lined up all day of little kids wanting to run trains this is a different story. Also I power the tracks from a transformer and turn the power down a bit so the kids cannot run trains too fast off the tracks, thus the kids try to force the speed control knob past the stop to try to get it to go faster.

When Percy and James LionChief remotes came out they were added to Thomas for the kids to run. And we were off to next show. We have kids wait outside the fence then we squirt hands with hand cleaner, wipe dry with a paper towel and then hand them the remote with parents helping, making it clear to make sure kids do not turn knob past the stop and that there is a delay. Sure enough remotes were broken over the weekend, I sent them back to dealer for replacement. When I called Lionel customer service to try to discuss the issue and if it could be better built to prevent damage they were not interested instead telling me to just send remotes back to my dealer for replacement. Dealer said this was a common problem with the remotes.

Next train show I put a few buttons out for the kids to push but no remotes. I taped the speed control knob so it could not be moved then occasionally let kids press the sound buttons.

With warranty only so long it was soon going to be a problem if they kept breaking and when I called Lionel they said they did not have any spares in stock or parts to repair the remotes not a good sign when warranty was up. So with the remotes having broken a few times it was time to find a solution.

So here is how to fix the LionChief Remote if the speed control dial gets turned too far and breaks. It will then just spin and not control the speed of the train. You should be able to fix this in under an hour. Note if it is still under warranty suggest you send it back for replacement from your dealer, if Lionel is not interested in talking to us about the problem if enough remotes get sent back then they might get the idea and fix the problem so the remotes are kid proof.

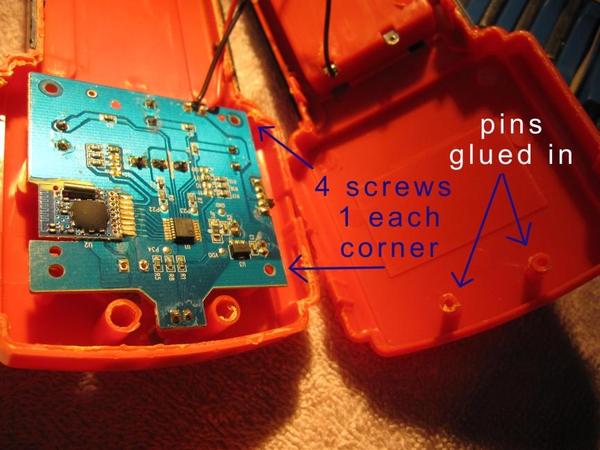

First pull off the speed knob it is attached with rubber cement, you might try a flat headed screw driver underneath to help pry it off. I carefully pried a broken remote apart everything is glued together with what seems like rubber cement. There are 4 tabs that need to be pushed in, on the handheld part of the base to release on the stops, and 2 on the top of the remote sides see photos. Also at the top of the remote are 2 round pins that are glued into slots. When it comes apart be careful not to break off the wires that are attached between the battery tray and circuit board. 4 screws hold the circuit board onto the base. And there is large nut under the control knob that holds the speed control; potentiometer in place. When you put it all back together you might want to apply a bit of glue or tape them so the kids cannot pry them apart. Also the battery cover after time the little tabs break off and you will need to wrap it in tape to hold the battery cover on. Need this part stronger Lionel.

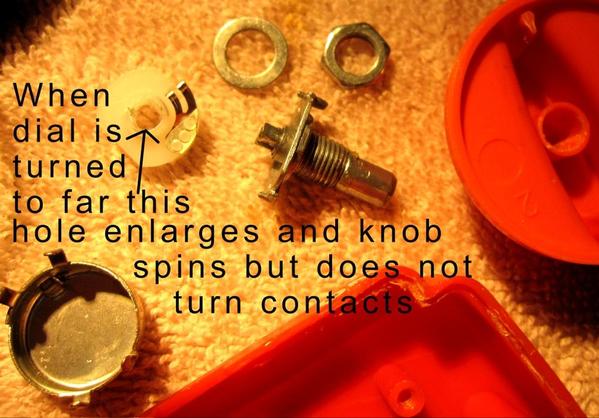

I could not find a good match at the electrical store for the potentiometer so I took apart the one on the control to see how it was assembled and what broke. To get it apart I bent up the dial with the pins and bent back the metal tabs to take the back off.

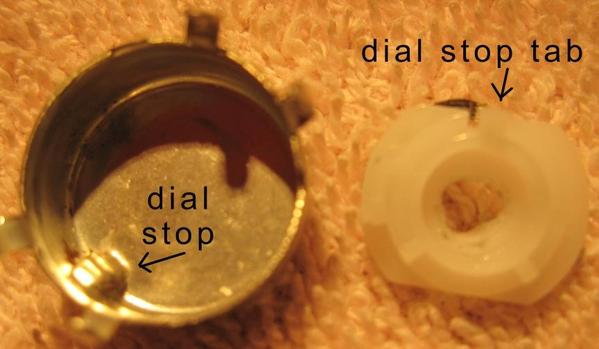

You can see that the plastic white piece with the metal contacts sits inside the metal case. The plastic tab on the white piece stops on the metal knob as shown, that prevents the dial from spinning all the way around past the full speed forward position to the full speed reverse position. As can be seen when the kids force the control past the stop what happens is the inside of the white plastic thing that fits on a half circle piece that connects to the speed control knob breaks open the plastic so it is round not a half circle so it spins around and does not control anything. As I could not find a suitable replacement I just used some super glue for plastic to remount the white piece to the metal dial and remounted it all.

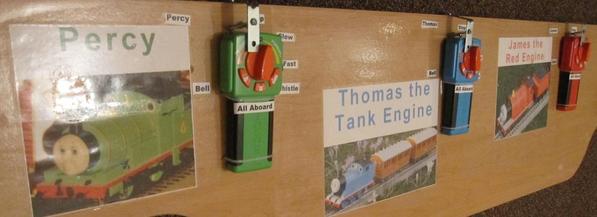

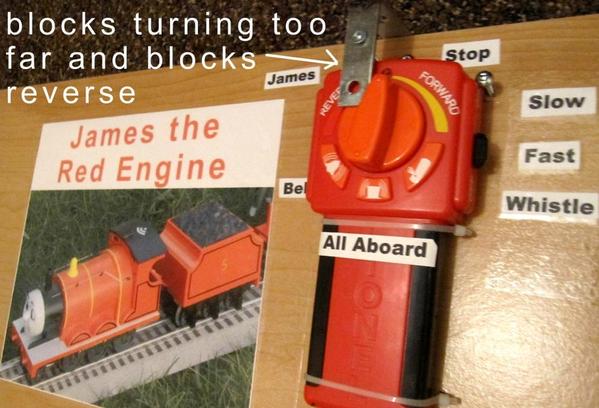

For the next show you can see the photos of the control units mounted to a board with metal bracket stops so the kids could not turn the dials past the fast position and prevented the knobs from being turned to reverse that stops derails with longer trains. This also made it a bit easier so the controls were attached so I did not have to worry about a kid walking away or dropping a controller and I was able to label the controls and pictures of the trains so the kids with parents help knew what they were controlling. This lasted most of the weekend but some kid managed to bend the metal bracket out of the way and turn the knob to reverse then force it past the speed stop and breaking the control again. I am going to add in some more brackets and wood to make the brackets a bit stronger and more kid proof.

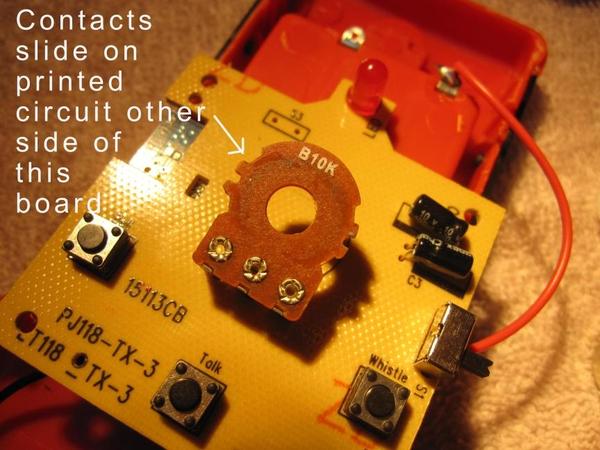

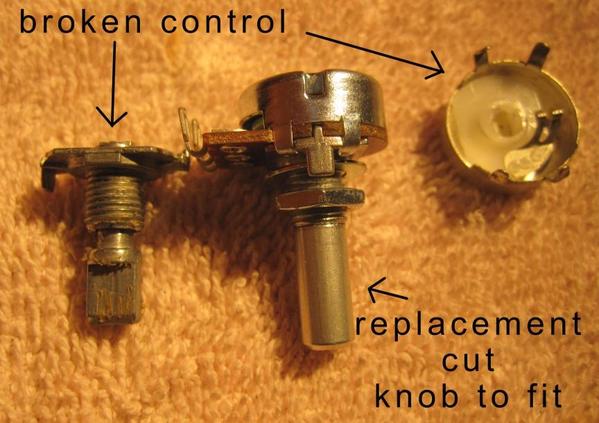

This time I went to a different electrical store and picked up a few different potentiometer designs, used a dremel to cut down the post a bit to fit the red speed control knob. I just cut the board electrical tabs off and resoldered the new control. There are various designs of the potentiometers available for around $2 each. Look for a 10k Ohms linear ½ watt. Find a knob that looks a similar size and unit similar height to the one mounted on the board. The repair this time only took about a half hour to replace.

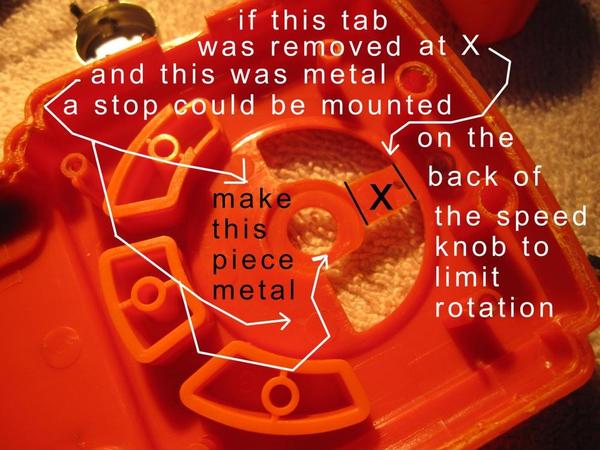

If you look at the control unit; I think that if Lionel were to make the base of strong metal instead of plastic where the speed control bolts on, remove the tab as shown at the top (X), then have a reinforced post under the speed control knob that rotated in the open space this would stop the speed control knob from being turned past the internal electrical stop, past the fast forward or fast reverse positions. Thus preventing the potentiometer from being broken.

If anyone has any other ideas on how to kid proof the LionChief remote happy to hear it! If it breaks and is out of warranty trust this will help you repair it easily.

![l3[1] l3[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/29868550308712440/filePointer/29868550308712492/fodoid/29868550308712476/imageType/MEDIUM/inlineImage/true/l3%255B1%255D.jpg)

![l3[1] l3[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/29868550308712440/filePointer/29868550308712492/fodoid/29868550308712476/imageType/SQUARE_THUMBNAIL/inlineImage/true/l3%5B1%5D.jpg)