I have wired my six 027 switches to 14V ACC Power. But the switches buzz when a train car crosses a switch. I have a wiring diagram attached that shows how to make the buzzing go away. This does work for one switch for sure.

My question is will this circuit work if I connect all of my switches to the same 7R to 9R circuit? If not all, will the Diode-Resistor-Capacitor arrangement support multiple switches, and then how many?

It is possible if I build a longer than normal train, that four switches would be on the circuit at once. Under normal operating of my maximum train size only three switches could be on the circuit at the same time.

Any suggestions on this would be appreciated.

Thanks,

Eric

Replies sorted oldest to newest

perhaps you could clarify, what type of O27 switches are you using?

Some discussion of the 1122 switches here: https://ogrforum.ogaugerr.com/d...ent/9173459950585279

You have to be careful running DC into an AC coil. The capacitor boosts input voltage by 41% and DC current goes through the coil with less impedance. If you do this lower the voltage until it just works,then add a volt or 2.

Dale H

Dale,

Are you saying that the capacitor output is DC? I thought that this was all AC. Unfortunately I'm not electrically inclined so, I was presuming that the AC coming out of the CW-80 ACC terminal was going through the Diode-Resistor-Coil connection and then through the Capacitor back to the ACC Ground as AC something? I don't know if it is current or voltage. Unfortunately that is where I break down. Hopefully someone out there knows that answer and can pass it along.

Thanks for your input.

Eric.

The diode provides half wave rectification and the capacitor charges it to peak. 4700 uf is a big value cap. The DC current is what takes out the buzz I assume. I cant make more sense out of it since I have no experience with the equipment shown and how it all works together. Maybe John or some engineer can look at it to see if I am right. I might be missing something.

Dale H

I think you may need separate capacitors, though you can probably charge them all from one source. It's not clear to me how that is wired to O27 switches, most don't provide for external power in any case.

Thanks Dale & John.

You are right John about the switches usually not supporting external power. However, Lionel have provided a solution that, through a modification so you can run the 1121 & 1122 switches on ACC power. See this link: http://www.lionel.com/Customer....cfm?documentID=6480

I've wired my switches accordingly and now am about to implement the above fix to try to eliminate the switch coil buzzing. If you follow my diagram above, the switch 1-6 wires to the block are actually the newly installed switch external coil-wires from the video.

Comments on that?

Thanks,

Eric.

I'm guessing you'll need separate capacitors, as multiple switches would discharge the single cap and probably not manage to throw the switch. At least, that's probably what I'd consider.

Ericlinda, if you show us your track plan I can make suggestions regarding capacitor discharge power supply for your switches. I've modified and used older 1122 switches with capacitor discharge power and they work well that way, but you probably need individual supplies for each switch machine. These other links have additional info.

https://ogrforum.ogaugerr.com/d...ent/9173459950585279

See the first AND last posts

https://ogrforum.ogaugerr.com/d...023#9595974415919023

You also need to be sure you have insulating track pins in the correct locations for your switches. https://ogrforum.ogaugerr.com/d...80#10581454654064580

If you do an advanced search on "1122 switch" there is a bunch of info out there.

You might be ahead of the game to minimize your use of these switches if you can.

OK. Here is what I can tell you easily in written words rather than talking, so you can get an appreciation.

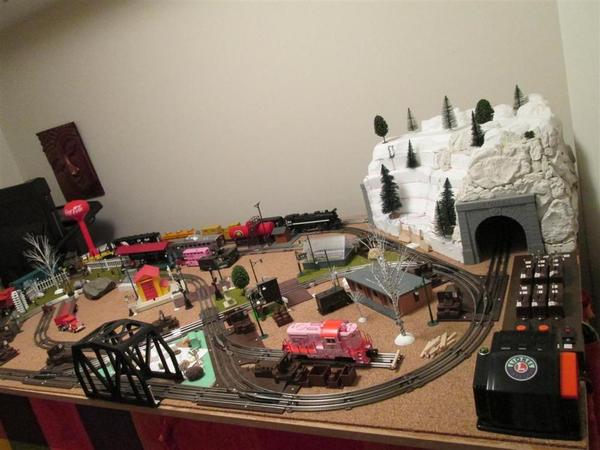

PIC 1 is my layout on the 4x8 table before wiring. PIC 2 is the result of evolution to 3 wiring blocks. PIC 3 is final with addition of two more wiring blocks (sidings off Figure8) It has evolved but I will give you the summary. Tunnel-mountain with waterfall & dam is a work in progress, as is grass and ground cover.

Main three blocks are: B1 is mainline including figure8. B2 is interim loop from left 1/2 of figure8 to entrance to mountain on back of layout. B3 is station siding. B4 is engine siding in left F8 loop. B5 is in left F8 loop.

The three sidings use Lionel manual switches.

Right now track only is on cw-80 track power. All auto switches and all accessories are on cw-80 accessory power.

Accessories include: 2 uncouplers, barrel house and Coke tower lights, 153IR, and gateman.

All track and accessory items are wired to under-table panel and cross-connected to power, ground, control switches etc.

I can show you the panel and wiring spreadsheet if you want to see them, but for now I'll say that is not necessary.

Thanks for this interest and help. It is well appreciated.

Regards,

Eric.

Attachments

Eric,

I'm glad that you posted this question - it's something that I can supplement my article that I sent to you.

BTW: for anyone that wants one: I submitted an article to OGR on how to do this - the same article that I've sent to Eric and about 100 other people. Email me and I will send it, along with pictures, to you.

Eric asked a great question (because of the price of the electronics) and I would love to confidently add comments based on what we learn here. I did mention, clearly, in the article that it was not me that devised the schematic but rather a person from the CTT forum. No I didn't mention CTT, just the fellow's name.

thanks Eric for posting - walt

Track plan with turnouts numbered for reference.

The thing about 1122 switches is, they are a "cheap and dumb" version of non-derailing switch. They draw power through one of their solenoid coils whenever metal wheels are on the switch, if the track or switch machine has power to it.

Converting them to fixed voltage input is a definite improvement to make them operate more reliably. Using capacitor discharge power is also good, but a capacitor power supply takes a few seconds to recharge. For the layout shown here, you pretty much need a capacitor supply for each switch. The large capacitors are somewhat expensive. I would suggest not powering the non-derailing feature for switches #7 and #8 to the spur tracks.

Depending on the length of your trains, one train may be traversinging three or four switches at the same time. All drawing power when metal wheelsets are on the switch!

I would suggest, for starters, that you try running fixed voltage to switches 1 through 6, using a separate transformer which is properly phased. Adjust the voltage to the minimum that will reliably operate the switch machines. Where you have switches close to the table edge, a train can derail and fall if the switch doesn't throw to enable a trailing move.

Also be sure you have insulated track pins on all these non-derailing switches in the proper locations as shown in instructions:

http://www.lionel.com/media/se...ents/70-5121-250.pdf

This photo shows an older Lionel 1122-E switch but the insulating pin placement is the same as your newer switches should have.

Attachments

Ace,

Great job on the diagram! Thanks for that. Switches 7 & 8 are manual so don't really come into it(no non-derailing function). The only thing to remember is to reset the path after your engine leaves the siding- beware of derailments. One comment I would like to add is that although Lionel (on http://lionelllc.wordpress.com/projects-and-tips/) mentions that the switches operate best at 14 volts, I find that my cw-80 transformer snaps them pretty good at the default transformer setting of 10-11 volts. The thing about my layout, at least now, is that the only ACC constant draw is the blinking Coke tower, the barrel house light and the gateman light. Possibly if I add some street lamps later, after I add some roads I might need to bump the voltage to achieve the needed current for the lamps. Apparently the switches only use voltage since there are no lamps in them, so for now I should be OK.

Thanks to you too Walt for your information on the capacitor solution.

Regards,

Eric.

Ace, thanks for making those observations. Yes, the capacitors are THE expensive part so I can see why Eric wanted to minimize the quantity.

Me, not being electrically smart enough to know, was helped by your comments.

ERIC: yes, I remember using way less than 14V too.

- walt

I got some of the 1122 switches with other misc secondhand train stuff and repaired them, also converted them to fixed voltage input, then tried them out in a couple temporary setups:

They work, but ... I don't like they way they are triggered by every train. They make noise and cause wheel sparking with every train across every switch. A capacitor discharge power supply is the best way to power them, but on a smaller layout you would usually need a capacitor supply for each switch because of the recharge time. And even then, a capacitor supply may not recharge fast enough for a switch on a reverse loop, if the train goes around too fast.

So they are rather quirky switches. I've eliminated them on my current temporary O27 layout project. I would suggest reconsidering track plans that use a lot of them. With fixed voltage input, you could use an electrical switch to cut off the power to these track switches if you are going to cruise your train around on the same route, but then you have to remember to turn the power back on if you re-route your train.

The O22 and related non-derailing switches for conventional O are really a lot better, because they only trigger when appropriate to line up a trailing move through the switch, then they cut off their own power. I'm still pondering how I might be able to better use my 1122 switches on an O27 layout, maybe with a different track plan and/or trackside trips to somehow minimize their operation.

Attachments

Ace,

Your trial senarios are interesting and have me thinking. I wonder how Lionel gets the switch to cut the voltage after it is applied with the track voltage version, after the first activates it? There are no other control circuits I don't think. So why does the ACC voltage which again is only applied when requested continue to action the switch coils on subsequent cars when the track voltage version does not. There is more here than meets the eye. I think I will ask this of Lionelle in the Wordpress.com forum & see what he has to say. I'll let you know what transpires.

Thanks,

Eric.

Ace,

Your trial senarios are interesting and have me thinking. I wonder how Lionel gets the switch to cut the voltage after it is applied with the track voltage version,

That's just it - they don't. O-27 switches don't get cut off after throwing - any rolling stock on the switch keeps it activated.

Hi Rob,

OK then if the track power is still active, I wonder why the coils don't continue to fire (and buzz) as in the fixed-voltage senario?

Thanks,

Eric.

They do, just not at a fixed 18 volts. It goes up & down(and off) with the train speed setting.

This is the only saving grace for the 1122/1122E/5121/5122 type switches, otherwise, if they had the fixed voltage option w/o the shut-off feature of the 022, kids would have left their trains parked on activated switches & walked away, only to return to melted switch machines later.

Thanks for the reply Rob,

Yes I see your point. Interesting that you mention 4 models of 027? switches. I pulled out a box to compare and it appears that I was wrong about my model. Oops. I have 6-65122 (right) and 6-65121 (left) remote 027 switches. A couple are late 1990s and rest are 200?

I don't think there can be much difference between them until you reach the "O" guage level, with the plug-in conversion to fixed voltage.

Eric.

The 6-65122 and 6-65121 are just the 5 digit(catalog number) versions of the 5122/5121. They were actually catalog numbers 6-5122 and 6-5121 before Lionel went to the 5 digit system.

Ace,

I'm wondering if the possibly the capacitor does not fully discharge so it would seem to re-charge quicker after being hit.

I don't have these switches any longer so I can't experiment. But for the 3 years that I used the setup that Eric mentioned, I never had a problem with not being to able to activate a switch.

Or possibly the capacitor that I was told to use recharges real fast. Here's the parts that the fellow (Bob Nelson from CTT forum) had me use:

A 1N4001 50V Silicon Diode (part #276-1101. Two to a package).

A 100 Ohm, 10W Resistor (part #271-135. Two to a package)

A 4700 uF, 35V Electrolytic Capacitor (part #272-1022. One to a package).

- walt

Ace,

I'm wondering if the possibly the capacitor does not fully discharge so it would seem to re-charge quicker after being hit ...

- walt

Walt, I don't understand what you mean there. When a train goes across a 1122 switch it's going to discharge a capacitor supply for sure.

This is my capacitor discharge package used to power an 1122-E switch. Originally I used a 100-ohm resistor but it didn't recharge fast enough for a train going through a small reverse loop quickly, so I changed it to a 75-ohm resistor. The capacitor is 6800mfd 40v which I salvaged out of old electronics. Smaller mfd's don't work as well. I forget what my input voltage was, I suppose a higher input voltage would have helped.

If I was going to use 1122 switches in a small layout I would want to use a capacitor discharge supply for each 1122 switch. Except, capacitor supply still doesn't work well for a long train going through a small reverse loop quickly.

Like Rob says, you want to be careful not to leave a metal-wheeled train parked on an 1122-type switch with a constant fixed voltage supply.

Attachments

Walt,

I wonder if you remember what ratio of setups of the Diode-Resistor arrangement that you used to switches? Would one do for six? I'm not sure what their function is in this equation/ and just have one capacitor for each, say, pair of switches? or if I need a capacitor per switch then whatever, there is only six.

Hi Rob,

OK then if the track power is still active, I wonder why the coils don't continue to fire (and buzz) as in the fixed-voltage senario?

Thanks,

Eric.

I thought there was an internal limit switch which breaks the voltage to the coil. I do not see the buzzing as a big deal but simple DC operation may eliminate it also if voltage is appropriate. There are a lot of ways to circuit capacitor discharge into a machine. The 100 ohm wire wound is unexplained as to its function,I think if it slows the charge it is too big. Most all capacitors charge almost instantly unless a resistor is in series to slow it.

Here is a simple circuit for Atlas machines using a toggle. The resistor slows charge a bit to eliminate sparking on contact points.

http://www.jcstudiosinc.com/Bl...=411&categoryId=

Dale H

Guys,

I'm still trying to understand how the Diode-Resistor and Capacitor are affecting/controlling the 11-14 volts AC coming from my CW-80 accessory transformer to the switch coils.

Does the new circuit block the direct AC and only allow voltage to be supplied to the coils from the capacitor? If that is the case I can see that there could be an issue if one capacitor has to fire more that one switch in close time proximity.

Am I correct is thinking that the reason there is no more buzzing is the lag for the capacitor to reload and refire?

Ericlinda, the capacitor provides a limited surge of current to operate the switch machine. Capacitors like we are using here store a DC charge, not AC. So the diode converts AC to charge the DC capacitor. The resistor limits the flow of current to the capacitor, otherwise we don't get the benefit of a limited surge of current from the capacitor to operate the switch machine coil. Without the resistor, a switch machine will get the burst of current from the capacitor AND continued voltage/current from the transformer, which might fry the diode.

Please review the additional explanations already given. You can use the same capacitor power supply to run multiple 1122 switches with non-derailing function only if there is an adequate recharge time when no metal wheels are on the switches in question, as I explained previously.

May I suggest that you try what I suggested previously: try running fixed voltage directly to switches 1 through 6, using a separate transformer which is properly phased. Adjust the voltage to the minimum that will reliably operate the switch machines. If that works OK, never mind the capacitor power supplies. Just don't park trains on the powered switches for too long.

If it was me, I wouldn't be using that many O27 non-derailing switches so close together on one small layout for the reasons which I tried to explain previously, and learned from personal experience.

The #O22 switches (with O31 curves, not O27) have electrical cutoff contacts built into the mechanism; they are a "smarter" form of non-derailing switch because they do not continue to draw power after they throw the switchpoints.

Ace,

I tried your other transformer at a lower voltage idea and voila, you are right again. Almost the same as if using track power. I used the transformer that my starter train set NY Central came with. It's a 77W , 3A and also does 18V according to the white lettering. I set it at 2 notches into the bottom of the green line. It measures about 7-8V on a meter. (My regular transformer is set for around 11V on ACC.)

When reversing a long train through switches 3,4,5&6 on your diagram, 5&6 weren't really happy just going through the open switches, but at the reduced voltage level not too noticable. They moan a little but do not buzz as before.

Funny thing though, I don't get the same reaction from the switches when the train goes forward through there, from either direction. I wonder why that is?

Thanks again for quality information and feedback from you and our other great contributors, making for an excellent forum. I will provide feedback on my experience when I get the electronic devices expected by Thur or Fri.

Best Regards,

Eric.

Something else to consider, when a train is crossing 3 or more of those switches at the same time, they are all drawing power (metal wheels bridging the non-derailing circuits), possibly up to an amp each depending on the voltage supplied, which may be taxing a smaller transformer. Best Wishes on your project!

Ace,

You are absolutely correct, and this is why many of our fathers invested in the KW's or ZW for our 027 layouts when we were kids. I still have a complete 027 layout, with many switches and the ZW runs it perfectly even today. Also the O Gauge Tin Plate Trains run on the 027 track and 1122-E switches, even the big 2810 Crane Car runs right thru the 1122-E switches with out a problem.

PCRR/Dave