Despite not being train parts, the detail you are showing on the ship parts really show what is possible. So much more detail work that could be done. I bet a fully detailed roundhouse with tools and equipment would be awesome if done with the type of details you are showing

Miles,

I have not followed for a while. I am glad to read about your wifes' recovery. About your upcoming article for OGR and seeing the incredible things that you have been producing. I am very happy for you my friend.

Thanks guys! Al! Good to hear from you. BTW: The 3D CAD and printing I'm doing for the current project is essentially the same as I've perfected in doing model architecture for the RR. It's the capablility that's the theme, not the output.

Congratulations on the article, Myles!! I’ll be looking forward to seeing it!!

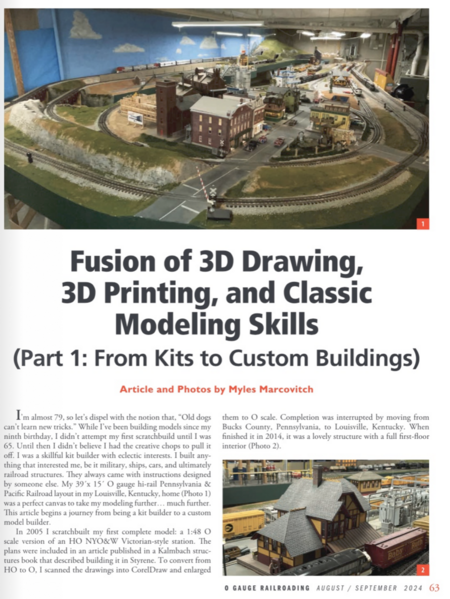

I just read Part 1 of my first OGRR article, "From Kits to Custom Building…" I am getting via the digital edition, but it looks pretty good. Let me know if you've read it and please give me feedback.

Attachments

Add Reply

Sign In To Reply