We had a great time. Toronto is a fabulous city, way exceeding all of our expectations. They are building tall buildings like crazy (kind of reminds you of Dubai), lots of traffic, lots of diversity, great dining, very nice people. We did four days there staying at the Four Seasons in the Yorkville Area (like Rodeo Drive on Steroids). All of the restaurants were within walking distance. Yorkville Rd have more supercars in one block than I've ever seen. Two Mclarens were parked 30 feet from each other. I've never seen one Mclaren on the street let alone two.

We then did 4 days at Niagara on the Lake. A total change of pace. Lovely town and again, nice folks. Lots of wineries and all of the output is required to be sold in Ontario only. Very strange. We did a full day at Niagara Falls and did the "Behind the Falls" tour through the tunnels, and the old Powerhouse which has been dramatically refurbished and was a great place to visit. They've opened the 2,200 foot outlet tunnel that was the discharge for the turbines that exited an opening in the canyon wall between the Canadian and American Falls on the Canada side. They've paved the tunnel and built a nice observation deck that's just above water level. Great view of the Falls. I made a movie of all this and will put it on my FaceBook Page.

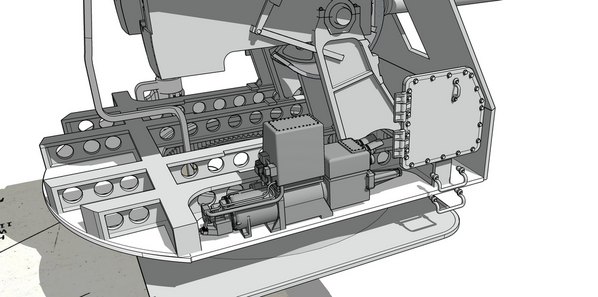

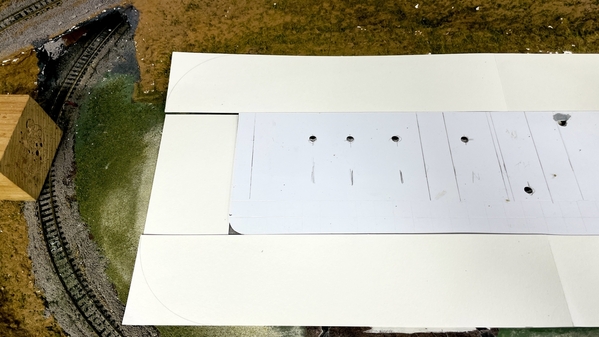

I haven't been sitting still model-wise. Glazing windows, final painting, continuing to tuneup the trackage, etc. I drew and am printing the last of the four buildings I'm doing: The First National Bank & Trust Company. This project was drawn entirely from Google Earth overheads and street views. You can measure the foot print in the overhead shots and estimate the wall height looking at the change in elevation as you move the mouse pointer from the base to the roof. I used SU "Match Photo" to the initial proportions correct.

Here's the building. Screen print from Google Earth Street View.

Here's a screen print of the above in the Match Photo Mode with my drawing superimposed over it.

And here's my drawing of same. Pay no attention to the mismatched clock faces. I'm not going to have clock faces. In n-Scale, the faces come out to the size of a period. If I can I will attempt to make a decal out of the graphics, but it's a long shot.

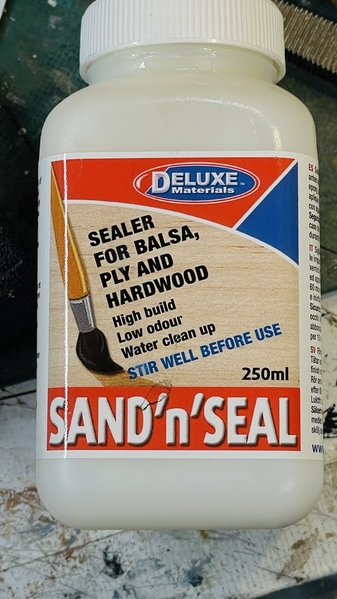

Now for a techical aside.

As many of you probably have gathered from my 3D printing experience, I had a fairly high failure rate, and warpage problems. Very fine details were very fragile and as a result, I tended to avoid them. I set my printer up when new with a flat test article that's used frequently, so I was under the mis-guided impression that my exposure time for my 80/20 resin mix was correct, so the errors I was experiencing were just the nature of the beast.

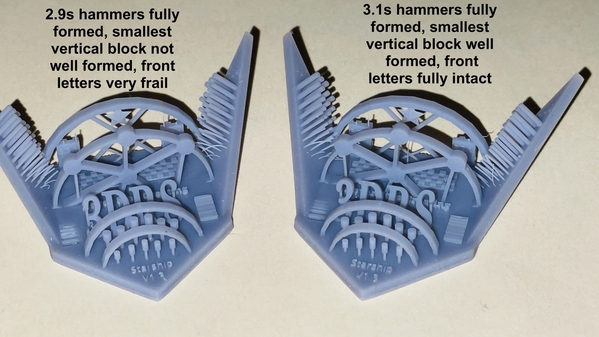

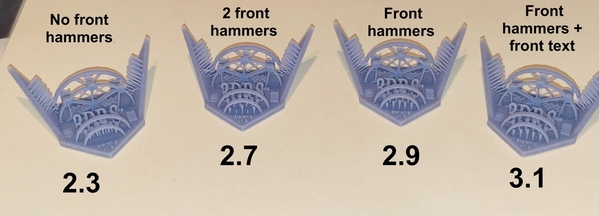

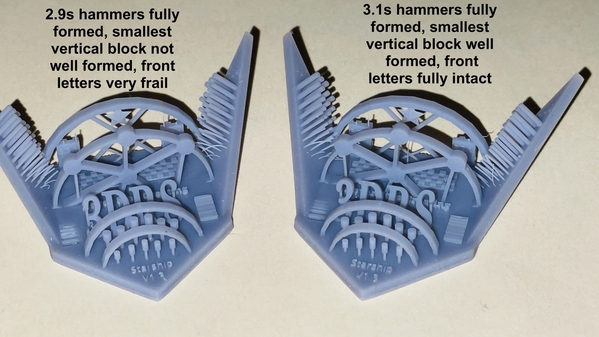

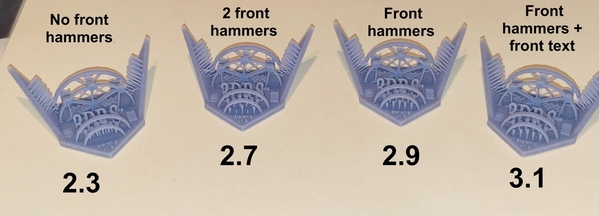

Then last week, on the Elegoo Mars3 Facebook group a discussion about exposure times led to a specific test article that was much more discerning than the flat ones. Since I had nothing to lose, I downloaded it, and ran tests from 2.1 seconds per layer to 3.1 seconds per layer. I was using 2.5 seconds. The test was very enlightening. I didn't just test lateral resolution, but also vertical capacity. And I found that I was underexposing by .5 seconds. The best result was at 3.1 seconds. That's a 20% difference and the results were dramatic.

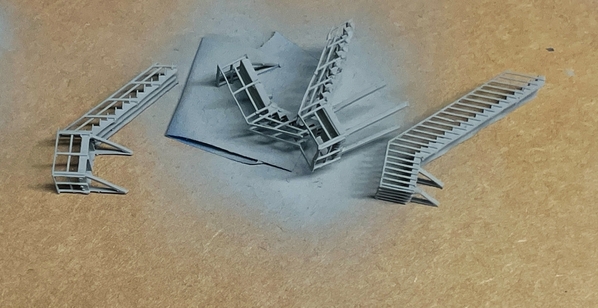

The "starship", as it's called, has 10 "hammers" in the front, that have a stalk with and enlarged head on it. The head is twice the stalk diameter. At my 2.5 exposure, only one stalk in the front had a head and most didn't form at all. There was also some very fine vertical relief lettering that just washed away in cleaning. At 3.1 all the hammers formed perfectly and the fine lettering was intact through post-printing and you could rub your finger over it without it breaking away.

Here's what the test results looked like:

I'm tellin you all this for two reasons. First anyone out there who's doing resin printing may want to try this test if they haven't already done so. Here's where you can download the Starship, plus instructions on interpretation of results.

https://3drs.com/pages/3drs-st...KfFrmHiuXiRETpgBD9cI

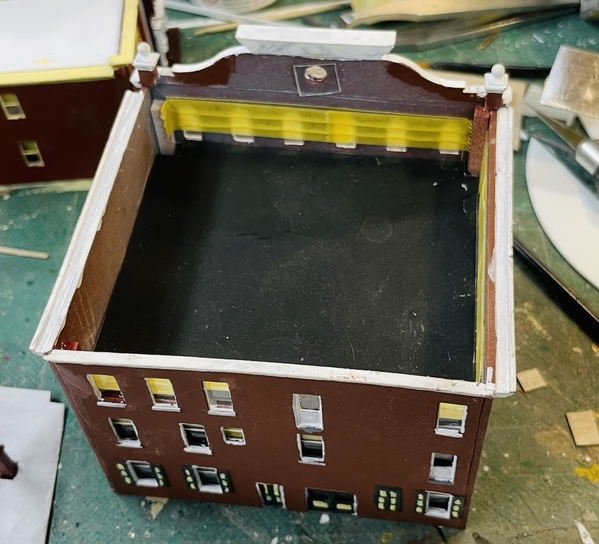

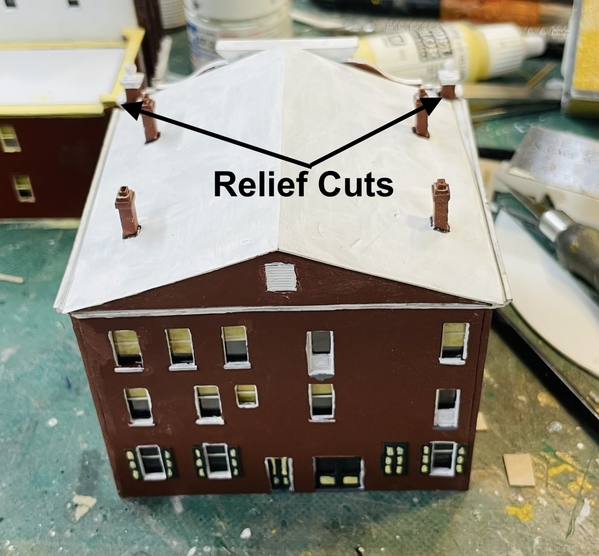

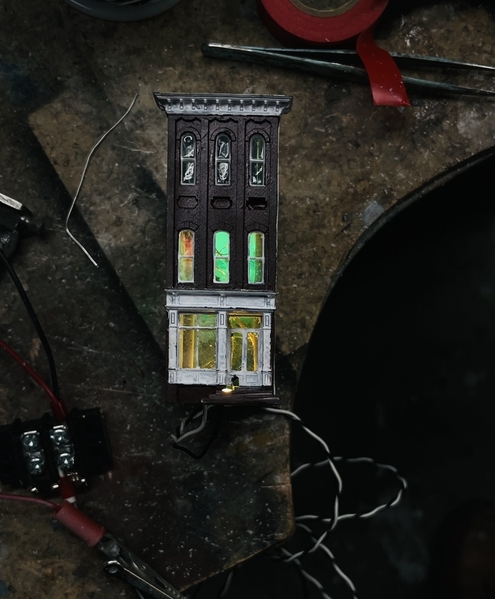

The other reason, is that I've been struggling with the results of underexposure for over a year and half, and today I printed the front and side of the bank building with no warpage and got pretty wonderful results on the multi-light windows. The lettering on the bank is perfect. There's a slight breakage on one of the windows, but I'll live with it. I could not have pulled off those mullions with the old exposure setting.

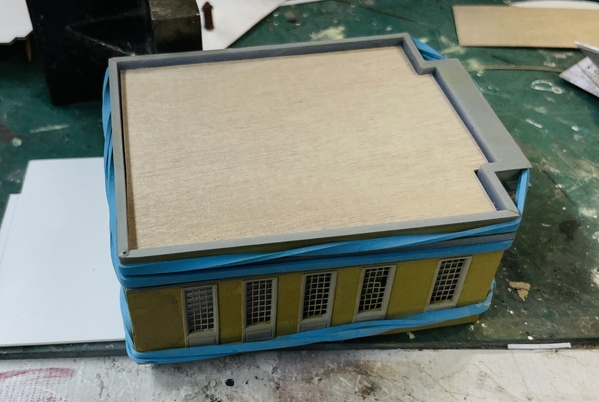

Here's the building assembled (sort of) showing the large lugs I'm now incorporating in the design to facilitate assembly. The corner miter is very tight and true and will probably not need any filling.

The rest of the building is printing now including the lovely bronze clock tower that's so iconic with this structure. It will be finished around 8 this evening.

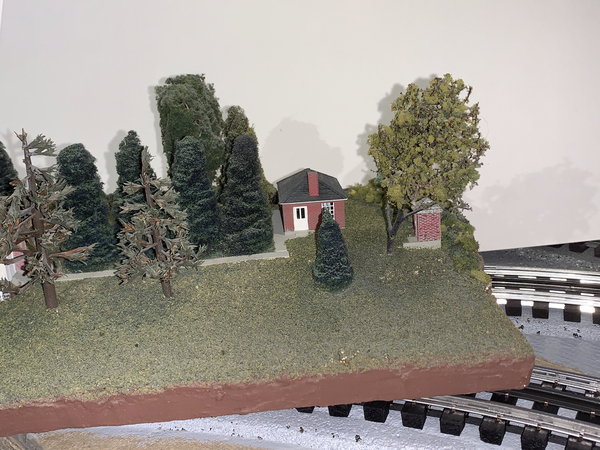

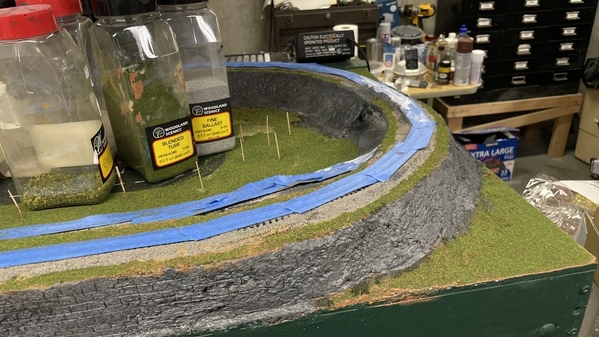

So here's the four Newtown, PA buildings I've custom designed and printed(ing) that will make this little layout more special. I got the glazing in the Hardware House and Newpaper Building. I finish painted the parapet caps on the Temperance House Hotel and got the chimney's final painted on hardware. I'm going to put the bank on the corner as it is in real life so the clock can sit on the corner.

Glazing the Hardware House store windows was challenging due to narrow glue surfaces and some irreglarities. This building would benefit from a complete reprinting, but I'm not going to do that. I was initially going to apply individual pieces of clear styrene, but changed methods to use larger pieces creased and bent around the window frames.

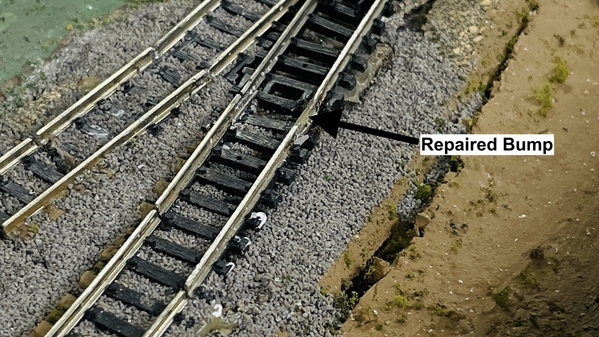

I have one spot on the track work that needs more attention. There's a dip and it's causing derailments. I don't want to re-lay track since it involves a lot of demo. I'm thinking to level it with some solder. But i have to do something.

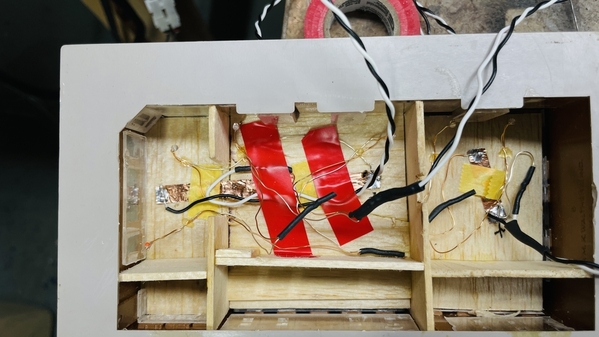

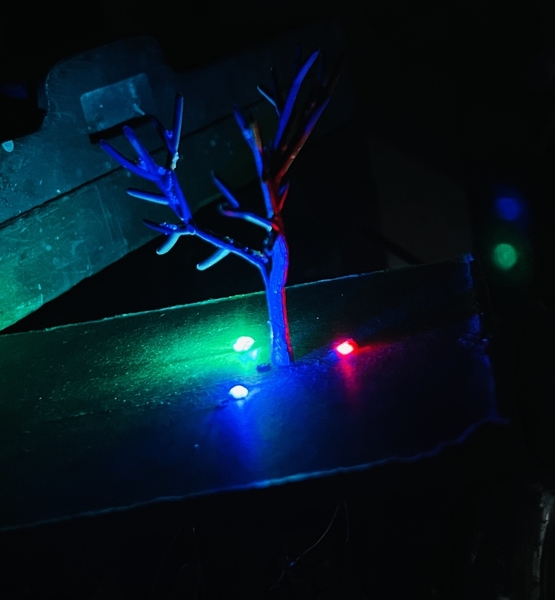

My last area of quandry is how to do the Christmasy lighting. I have some of those inexpensive string LEDs and am also planning to do something with fiber optic lighting, but I've haven't decided just how to approach it. If it were O'scale, it wouldn't be a problem for me. But at this scale, I'm still not sure just what I want to do. With fiber I could light the trees individually, and use the colored string lights in the lower levels of the buildings, but I'm not there yet. Your thoughts would be welcome.