I make my love of the White Pass and Yukon Route no secret. I've been customizing my own O Gauge White Pass stock for a while.

One piece of White Pass history I would like around is a model of their GE Shovelnose diesels.

I found a gentleman online that 3d modeled the Shovelnose in N scale. I asked him for a copy of his file, and he sent it to me.

My plan is to print this out in O Gauge and mount it to a postwar alco chassis.

Has anyone here ever done anything like this? Does anyone have any pointers or advice? I'm nervous to print it for $100 and then find out it won't work.

Replies sorted oldest to newest

3d printing is so new I do not believe anyone has done what you want to do.

but if you do print this please show pictures so we can all learn with you on how it goes.

Spend the extra money to have it printed on a high res printer

That is so great you are considering the 3D printing option.

I am currently enrolled in a 3D printing course at a resource center where we have access to 3 different printers.

My plans are to print small 0-gauge figures in any configuration I can imagine.

From there I will work up to bigger and better objects.

The possibilities are endless, 3D printing will be very commonplace in a few years.

Beautiful work Tom. There is nothing like the sense of accomplishment one gets from seeing there own craftsmanship at work.

![]()

One piece of White Pass history I would like around is a model of their GE Shovelnose diesels.

I found a gentleman online that 3d modeled the Shovelnose in N scale. I asked him for a copy of his file, and he sent it to me.

My plan is to print this out in O Gauge and mount it to a postwar alco chassis.

While I have no 3D printed engine bodies, I have had these present-day UP auxiliary water tenders made, which were originally produced in N and HO scales and then scaled up to 'O':

The third photo is the maker's own comparison of the three scales.

These are great models and certainly on the rails I think they look better than the imitation "flag" AWTs recently offered by both Lionel and MTH. They accurately reflect the modified AWTs as built for present-day UP excursion trains. That said, I'd make three main points about scaling up from smaller scales to O:

1. Using a relatively fine or high-res printing material, the shells of these models are extremely light; each one weighs about 3.25 ounces, so they are featherweight compared to brass - let alone die cast. That translates into fragility; whereas in a smaller scale than O you might not need extra internal supports for the body panels or roof to keep them from distorting in the printing process or in use, with O scale I think you do. So simply scaling up drawings for printing out something that is as large as a diesel model is risky. I mounted these shells on a Lionel replacement part frame with the related trucks and couplers so as to ensure as far as possible the shells bore no weight when placed in a full train with trailing cars.

2. I think of conventional 3D printing as in reality finely layered 2D printing. With a very fine printing material the layering is not so obvious but it will be visible at close range, which leads me on to point 3.

3. It will take a fair amount of of work to prepare the printed shell for painting/finishing. I understand that most such prints come with a surface residue that has to be cleaned off with something like Goo Gone (by soaking in it) before you can start finishing the surface. Maybe the provider of your drawings has already told you about all that but I reckon it's worth mentioning.

Finally, maybe it's also worth mentioning that for lighting you'll probably need to drill out the apertures in the shell, which bearing in mind it's kind of like handling paper could be challenging.

All that said, the technology allows you to model prototypes neither the main nor specialist manufacturers do at present.

Attachments

Hancock52 that is really cool. When I retire in 5 or so years I am going to look into this

Spend the extra money to have it printed on a high res printer

I am planning on using shapeways.com not sure if they are Hi res or not.

Spend the extra money to have it printed on a high res printer

The AWTs shown above were printed by Shapeways. They have an ultra detail ("FUD") material option but it costs more.

Extra info on material and finishing can be found on the blog of the UK modeler who did the AWTs' shells for me; https://jamestrainparts.wordpr...present-o-scale-148/

One of the questions I have had about 3D printing is if you scale a 3D file up, will it lose detail or resolution like a photocopy does when trying to scale a paper original up on a copy machine. Based on Hancock52's photos, it looks like going from 1/160 or 1/87 to 1/48 had little (if any) loss or distortion of detail. Will be interested in Tom M's results.

Larry

Keep us posted on how the project is going. Are you intending to model it with "0" gauge, standard track? I know that the WP&Y is 3' narrow gauge, which would mean that an engine running on "0" gauge track but in scale for 3', would have to be in about 1/35 scale, or so. Kinda like MTH's model of the RGS "Galloping Goose". The resulting model was far too large for regular 1/48 "0" gauge.

Paul Fischer

A word of caution. the White Pass and those engines were narrow gauge I think. If you scale it up directly to 1:48, will it be too small for the chassis your plan to use?

A word of caution. the White Pass and those engines were narrow gauge I think. If you scale it up directly to 1:48, will it be too small for the chassis your plan to use?

The White Pass is narrow Gauge, but right now I'm not too worried about being prototypical. I guess I'm kind of making my own fantasy White Pass standard Gauge railroad. I'm scaling the model to fit the chassis I bought.

Attachments

by Hancock52

"Using a relatively fine or high-res printing material, the shells of these models are extremely light; each one weighs about 3.25 ounces, so they are featherweight compared to brass - let alone die cast. That translates into fragility...."

"Finally, maybe it's also worth mentioning that for lighting you'll probably need to drill out the apertures in the shell, which bearing in mind it's kind of like handling paper could be challenging."

----------------------------

Why couldn't the thickness of the shell be increased to eliminate this problem?

Dave

by Hancock52

"Using a relatively fine or high-res printing material, the shells of these models are extremely light; each one weighs about 3.25 ounces, so they are featherweight compared to brass - let alone die cast. That translates into fragility...."

"Finally, maybe it's also worth mentioning that for lighting you'll probably need to drill out the apertures in the shell, which bearing in mind it's kind of like handling paper could be challenging."

----------------------------

Why couldn't the thickness of the shell be increased to eliminate this problem?

Dave

The reason as I understand it is that it would require a substantial increase in the printing material used and that has a direct effect in terms of cost, especially if you are producing an O scale model which of course requires a great deal more material than HO or smaller scales. While I don't know the precise method of charging involved I was told that printing using Shapeways is costed in large part by the amount of printing material used for a given model. I suppose it might make a difference where what is printed is a one-off rather than a production run.

It is possible to design in reinforcing panels. After my tenders were produced the maker added some to the center of the shells to help support the tops, which have a lot of detail on them and I think are also a fairly wide span for printing using fine printing material.

That material is definitely not like styrene, ABS or other more familiar plastics, either to handle or work. I'd bet that in the future more durable as well as cheaper materials will become available.

I WANT one in On30!!!!! Been waiting for Bachman to do one. Keep us updated.

You have the hard part done.....the ART!!

You might also consider making a version that fits on an HO scale Athearn PA-1 chassis for the On30 crowd.

The WP&Y "shovelnoses" may have been rare birds in North America, but GE built similar units for export to South America and other places.

Another approach is to parse out the model into its various parts and then pick out those parts that make sense to 3d print. In the case of the engine the nose should be 3d printed (a small part) and the rest is basically a styrene box. Next would be details such as vents, etc,. I have a small 3d printer but I have done some large pieces with a fair amount of detail. All pieces shown below are o scale. Russ

stationary boiler for a power source a single print and is hollow

ballast hopper for a narrow gauge line (on30) printed as a single part

smaller parts but limited detail

I cannot wait for this to become a viable way to make complex locomotive parts. It is already close - some very good driver castings are being made with computer generated waxes.

But for such a simple carbody, wouldn't it be quicker to make it out of sheet styrene, or even wood? I have one of those ATSF early Diesels underway in aluminum, and the plan is to have the ends cast by using plastic built-up molds.

"A word of caution. the White Pass and those engines were narrow gauge I think. If you scale it up directly to 1:48, will it be too small for the chassis your plan to use?"

As long as you scale the shell up to fit your mechanism then, you should be fine. It might take some imagination to figure out how to mount the shell, but that is part of kitbashing.

I looked at printing in FUD "Frosted Ultra Detail" for my purposes the cost would be prohibitive, over $400. Maybe if I do a scale model in the future I will fork out for the more expensive printing.

I am planning on doing a standard print, and then sanding the model to my desired look.

My model will be more like a postwar diesel render than a prototypical model.

I looked at printing in FUD "Frosted Ultra Detail" for my purposes the cost would be prohibitive, over $400. Maybe if I do a scale model in the future I will fork out for the more expensive printing.

I am planning on doing a standard print, and then sanding the model to my desired look.

My model will be more like a postwar diesel render than a prototypical model.

I'm not surprised at that level of cost with that material. But frankly to me it seems like overcharging for the convenience of having your own drawings converted into prints.

Good luck with your project. With a basically slab-sided diesel body I would think you'll get the result you are after from a standard print.

First off $400 is ridiculous for a loco shell! Next think out side the box. The only special piece is the nose, the rest is a box with a detail piece added to the roof. I tried sending you an email but got no response. If you can send me the file I will give it a try and see what I can come up with. Russ

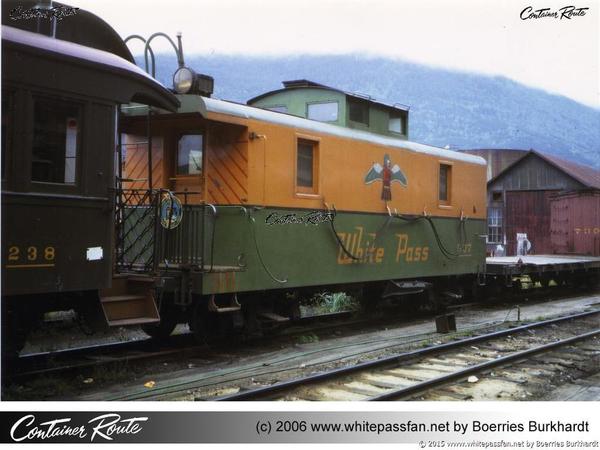

Not quite finished with the caboose, but it's coming along. I'm not sure if I wan to mount it to a production chassis or design my own. I'm waiting for my GE Shovelnose to arrive so that I can take measurements so that this model can line up height wise. I think they will look sweet going down the track together.

My 3d model of the GE Shovelnose was supposed to ship on June 10th but it was damaged during post production cleaning. Hopefully I will have it by early next week.

Attachments

so you have an 1/2 inch to make up, frt. rear. glue a plastic block on frt,, rear end of shell, use the frame screw rear, the frt. drill a hole in frame. screw from bottom to hold frt. of shell.

Looks great Tom.....are you going to sell them r are they available in the Shapways public library???

Dave this isn't my original design, so I can't offer it for sale publicly. However I do need to talk to you. I'll send you an e-mail.

AMCDave posted:Looks great Tom.....are you going to sell them r are they available in the Shapways public library???

Sent you an email.

aterry11 posted:Really nifty! Think they could print multiples of this dome assembly? They are becoming hard to find.

Al

They are just printers. Someone would have to reverse engineer it. Would you want it done in brass?

Tom M posted:AMCDave posted:Looks great Tom.....are you going to sell them r are they available in the Shapways public library???

Sent you an email.

I did not get a e-mail......thx

check profile for addy

Nothing ventured, nothing gained. Looks like a great pioneering effort. When somebody does an O scale McKeen car, I want one. But, if this was cost effective, manufacturers would have jumped on it...I suspect all is awaiting cost declines.

Mr. Tom M, Local library has a maker station and the ability to 3d image the assembled piece.

At this juncture brass plastic , or bubblegum would be acceptable..

I can find the kemtron end pieces but the proper wrapper, in 2nd pic above is elusive as hens teeth.

I have pretty much come to the conclusion that to finish the dome portion of my Northcoast Lmtd. is going to require I learn some more newer skills. Hey its taken 3 years to source most of the parts and proper blanks, cant quit now.

Attachments

Attachments

AMCDave posted:Tom M posted:AMCDave posted:Looks great Tom.....are you going to sell them r are they available in the Shapways public library???

Sent you an email.

I did not get a e-mail......thx

check profile for addy

The only email see on your profile is amx3 at hotmail. That's the one I sent it to.

I'm a lover of some C&O Steam Locomotives, and NYC Locomotives that I got to see/admire a a young boy of the late forties early fifties.

Now with this said, can a model of the C&O's "Super Mikado", K2/K3/K3a, and matching tenders, both Vandy 6 axle, and big rectangular 6 axle.

I'd also like some info on the NYC(Big Four) H10/H10a/b, "Super Mikado".

I've tried to get Lionel, MTH, as well as, 3RD Rail, to do them. I know for a fact that there is a good amount of detail, that can be had using a 3D Printer, but I guess that depends upon which one a person would have.

I think that the time is quickly coming ,that some of these "Odd Ball", so they have been call to me, locomotives will be produced, with some of the new "Buck Rodger's" stuff/equipment that's out there.

I know that there is considerably more to constructing a steam locomotive, than a diesel, but what you have shown is "Great" .................Brandy!