I decided to make layout control panels with an active touch track plan diagram when I built my operating and switching 027 layout with total 28 switches, starting in 1976 or forty year plus years ago. This is not a "set a speed" and watch the trains loop around or navigate the figure 8. We run multiple trains, switch out engines, couple and uncouple cars and change engines from the turntable and round house, etc.

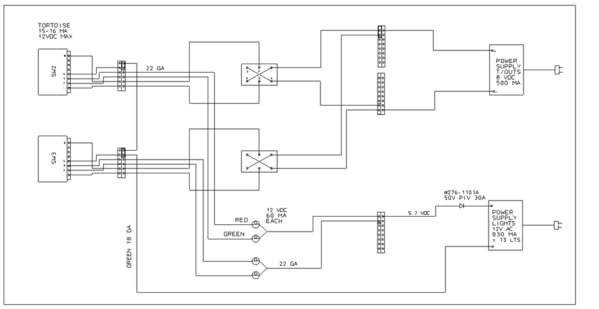

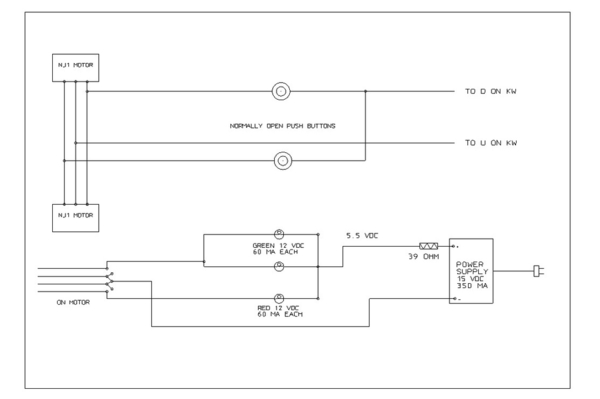

Note on Main control panel active touch layout diagram above: The red and green push button switches are for track switches. The blue push button switches are for uncoupling track sections. The black slide switches are for cutting on and off power the track section they are on. When WHITE shows completing the white of the diagram, the power is ON. When the BLACK of the switch slide lever is blocking the white track of the diagram, the power is OFF.

Model Railroading book shows an active touch track plan diagram control panel with 7 toggle switches located on the diagram. Most Lionel train show room layouts had a track diagram but the switch control switches were not on the diagram and they layouts mostly consisted of 5 or 6 isolated loops with only a few sidings. The book Greenberg's Model Railroading with Lionel Trains, Vol 11 of 1992, page 40 shows a control panel with 38 Lionel switch controllers lined up and sheet with the track plan below. I do not know how they identify which Lionel switch controllers operates which track switch.

There are at least three reasons I chose an active touch track plan diagram control panel.

One reason is I have 19 Marx 1590 track switches on the main train board and having that many switch controllers lined up would be difficult to operate deciding which control switch went with which track switch. The active touch track plan diagram makes it easy to find the proper switch. The uncouplers require an additional 14 switches to be matched with the uncoupler track section and would be hard to identify which switch worked which uncoupler track section. An active track plan diagram control panel solves both these problems.

A second reason is it saves space by combining the switches for the track switches and uncouplers and on the small track diagram. This is possible by using Radio Shack mini push button control switches which are located at the spot on the diagram where the track switch or uncoupler track is located on the train board.

A third reason is I like the looks of an active touch track plan diagram as it is less cluttered than a large bank of Lionel switch control switches and seeing the track plan helps identify the different tracks on the layout. Lionel used track diagrams to show a picture of the track plan on some of their showroom layouts but they did not have active switches to control the layout.

Note: The Main control panel has two LW transformers and will accommodate two operators. One operator can operate the whole main layout with the red lighted LW on the left and a second train can be run on the green lighted LW on the right which then will operate the outside loop. The inner loop and turntable will be operated with the red lighted LW on the Left.

Picture above of the Addition train board control panel with and active touch track plan diagram. This train board can be operated with the orange lighted LW to the right, a part of total L shaped layout or as a stand alone layout. The Additional train board can be operated with the green LW or with the red LW located at the Main control panel when part of the total layout.

One can see there is enough room for two operators at the left and that both control panels are close enough for one operator to work both control panels.

This active touch track plan diagram control panel has proven to work very well and I can not imagine a better way to operate the track switches and uncoupling track sections for my layout.

After having this active touch track plan diagram control panel for over forty years, one idea for an improvement has been come up. The improvement would be to have the direction of the switch on the diagram be illuminated in the route the tracks are set up to. The operating engineers memory is required now to remember what route has been set on the various track switches.

Further details for how I made the active touch track plan diagram control panel (post 8 of below link) , homemade $10 turntable and the whole layout are at my post title :

https://ogrforum.ogaugerr.com/...51#60135595715990351

Charlie