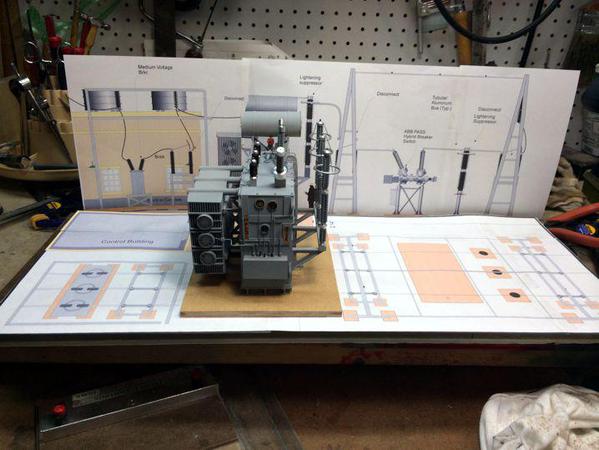

And with that compliment, here are some more details...

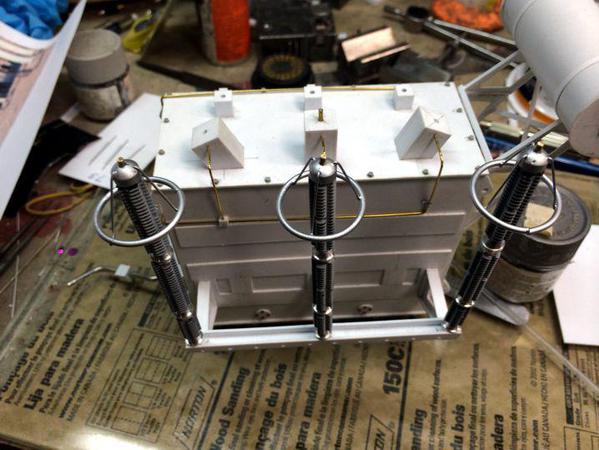

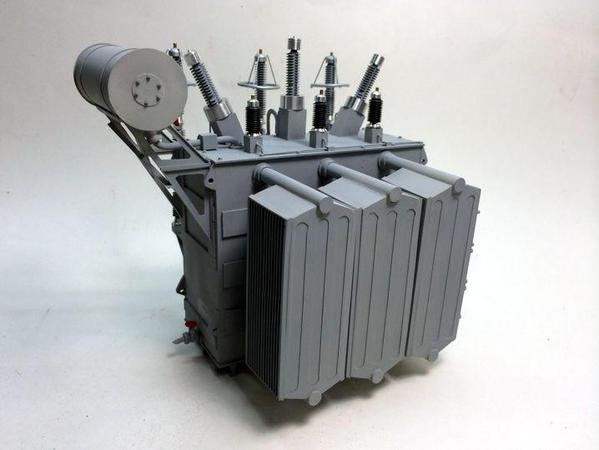

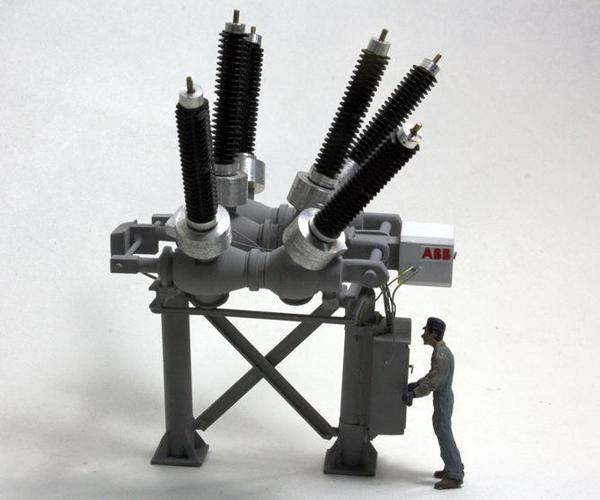

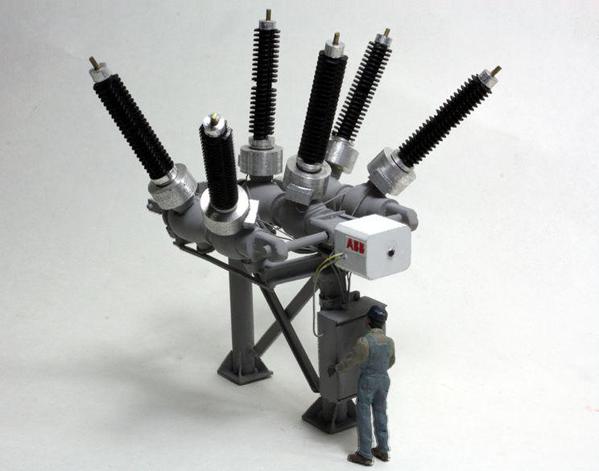

I finished the suppressor stacks and they're ready to be installed once the painting's done. I glued on the bushing bases for the secondary side and added two more conduit runs: radiator fan wiring and radiator temperature sensing.

Firstly, I did air brush the sky gray on the primary and suppressor insulators. I always force dry Tamiya and other water-based paints using a heat gun. I start it hot and then immediately click it on cool to keep it from melting the part I'm attempting to dry. The tool I use is a Top Flite heat gun for applying mylar aircraft skins.

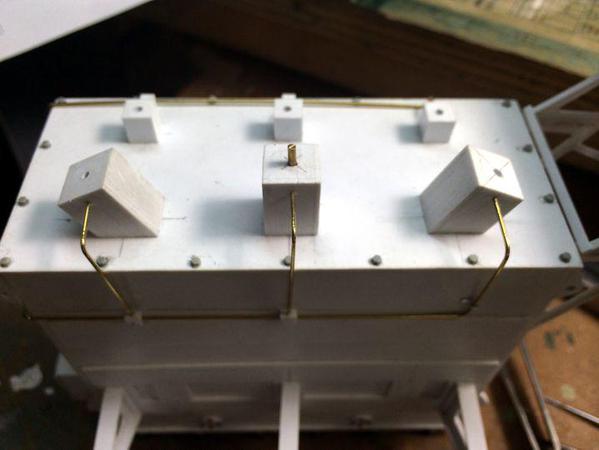

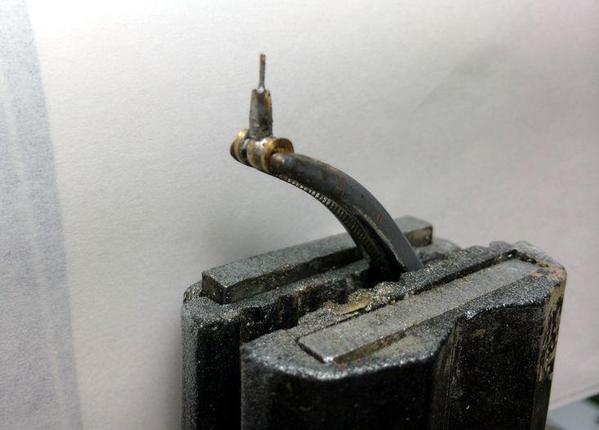

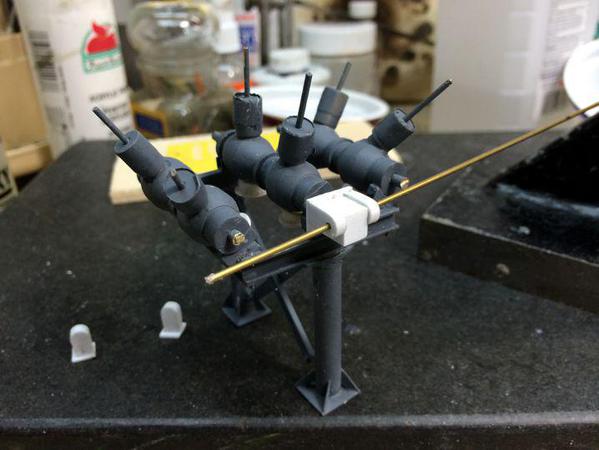

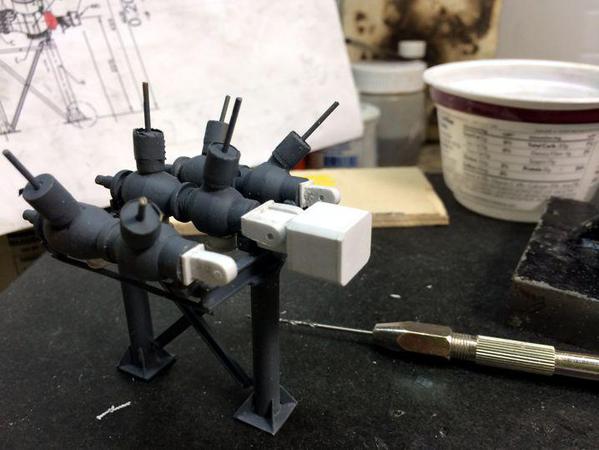

When they were dry I assembled the stack using a couple of V-blocks clamped to an angle block so the stack would be comparatively straight. I use CA between each part. Remember, they're all held together with the 1/16" brass rod.

The only problem using the light gray is that you can now see clearly that the "insulators" are not finned all the way around. But since they're so convincing from the viewing distance they're going to eventually lie, I'm okay with it. I would have had to machine them from scratch to make them and that would have been very difficult. I tried it on a test piece and was not happy with the results. In looking at these pictures I'm realizing that I've yet to build the corona rings. They're going to be challenging, but are so cool to look at that I'm willing to give it a whirl. I can't be any more difficult than building the hand-made masts and yards for the Battleship Missouri project that I did two years ago.

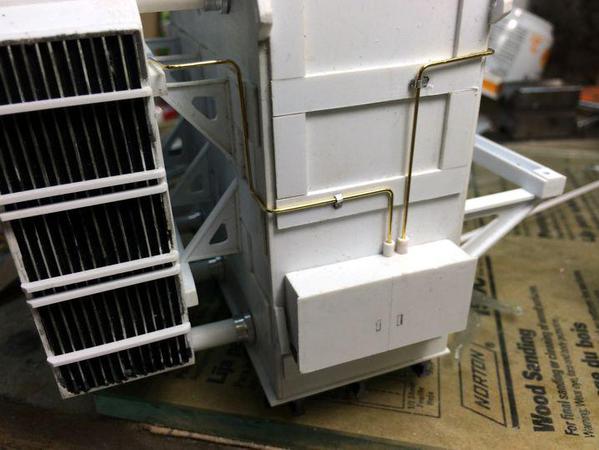

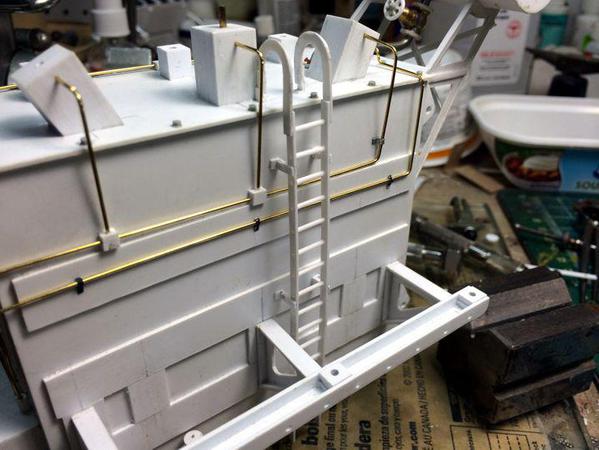

When these were finished, I created the radiator fan wiring conduits using the same scheme as I did with the current transformer conduits; i.e., making junction boxes and CA'ing the brass into them.

I didn't permanently glue this conduit into place. I will after the radiators are installed (which they are not yet).

I then formed a conduit that would go behind the radiators to serve as a connector to radiator temperature sensors.

This conduit is permanently glued since it just lies against the radiators.

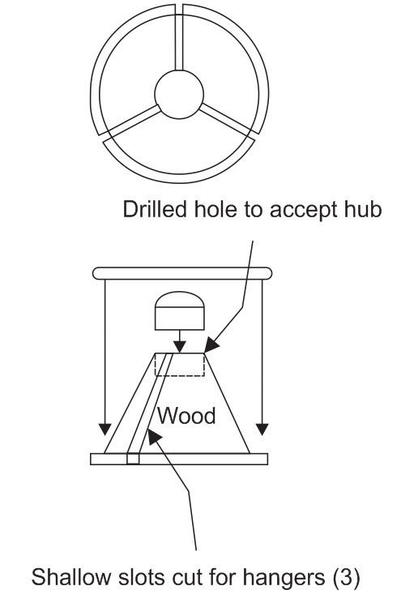

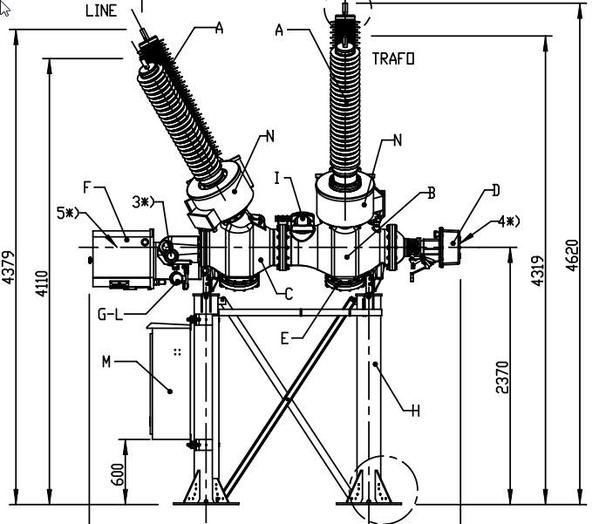

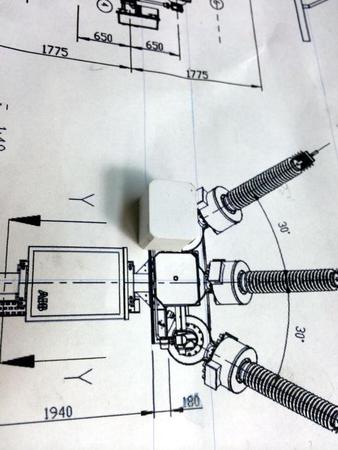

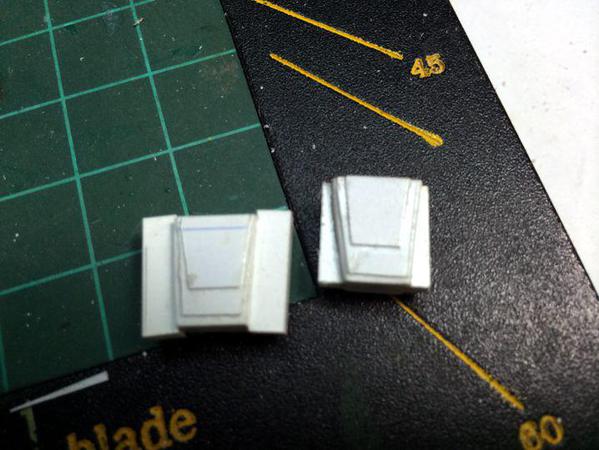

I realized that the secondary bushings were not yet installed so I made the bases out of some 1/4" sq. styrene, cut with a saw and miter box and then trued up on the Tru-Sander. The centers are the same as the primary bushings.

I'm going to use the same plastic Christmas tree fasteners for the secondaries as I used for the High Voltage transmission towers. For these I'm turned some nice, domed caps for them. I don't think they have current transformer bases, but I'll check my resources. If they do, I'll turn them too. It there are current transformers on them, I have to add more conduit for their sensor leads.

I have a very cute little spherical turning attachment for my Taig lathe that I used to make these perfectly domed shapes.

Tomorrow's the weekend and I usually don't do any shop work then. And next week is preparation for my #1 grandson' Bar Mitzvah with lots and lots of family and friends coming to L'ville from all over the country, so I may or may not get shop work then. If I do, y'all will know about it.