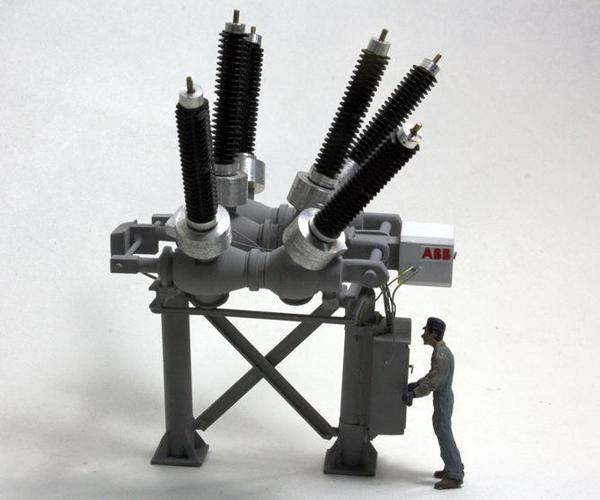

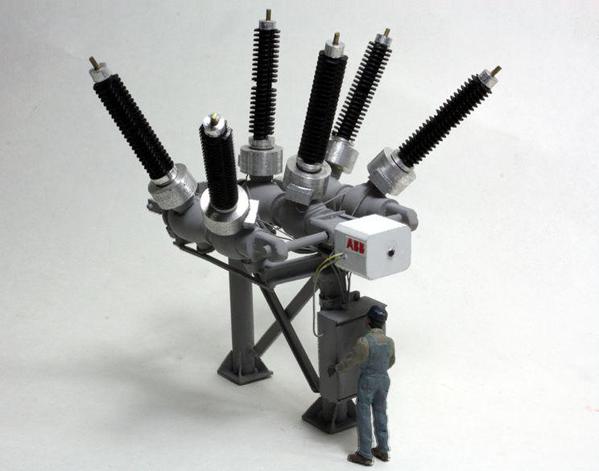

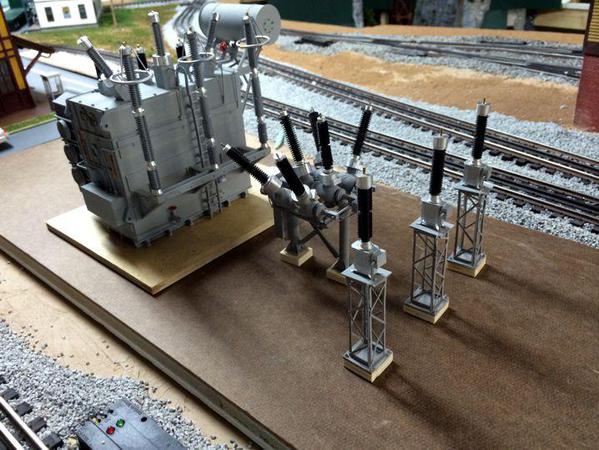

As I do each day... Thanks! It's a shame that I'm putting all this work in AND IT DOESN'T DO A SINGLE THING MAKING THE TRAINS RUN BETTER. It will make the trains LOOK better.

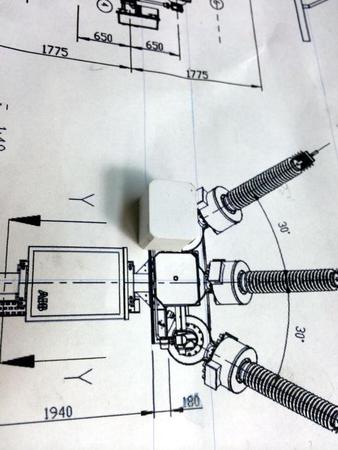

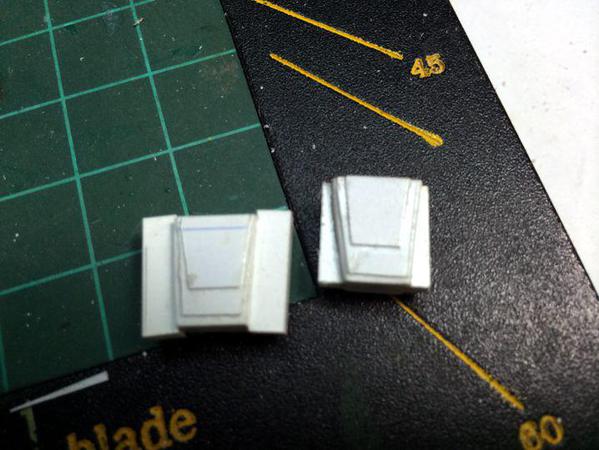

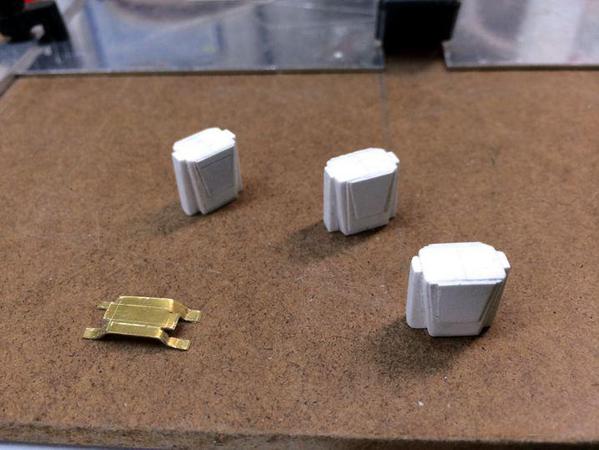

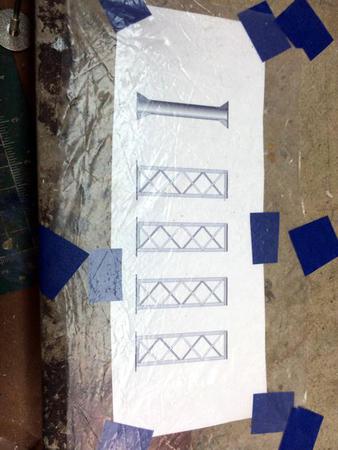

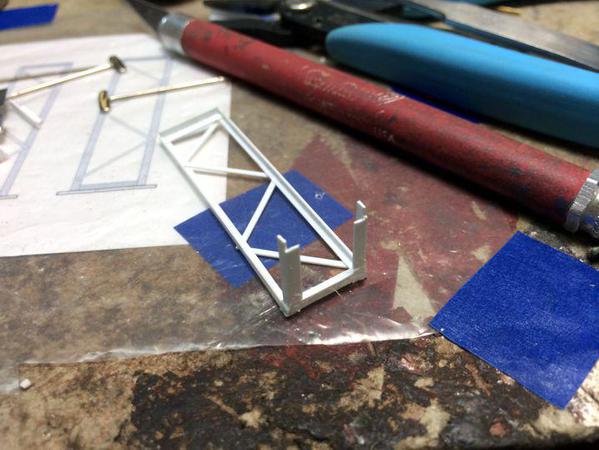

Worked on the breaker operating mechanism today. It's still not correct, but I may live with it. Let me explain. I first built the spring engine box. This went together sweetly. I used 1/8" corner reinforcements and .040" sheet styrene for the sides. I needed the heavier materials because the edges on this box are all chamfered 45º.

After it dried I used a V-Block on the precision sander to cut the chamfers. Worked great!

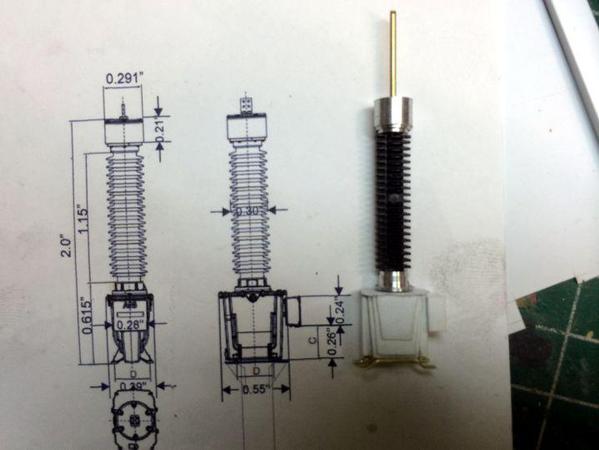

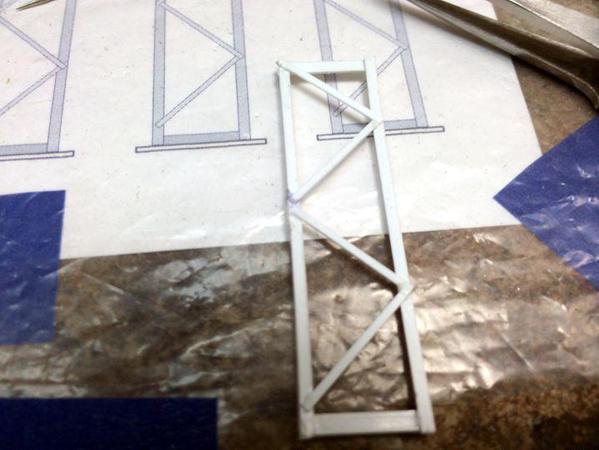

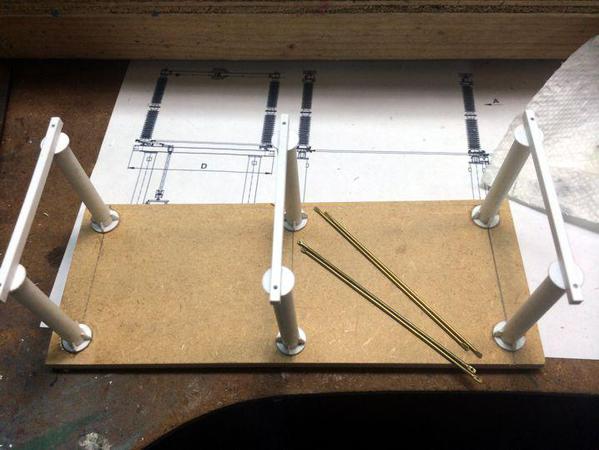

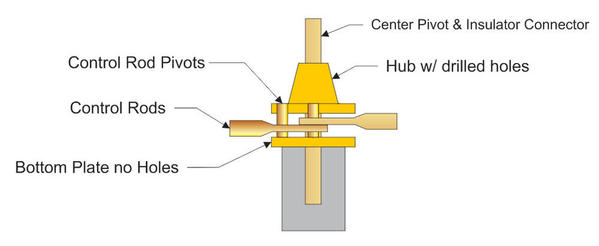

For the mechanism that attaches to the ends of the outboard breakers I needed to have a profiled part. The way I do this is shape a piece of stock and then slice off the pieces like salami. But I'm not completely happy with the shape, but it may be a AMS relapse showing its ugly head.

The 1/4" sq. stock that I used didn't have enough height so I laminated a couple pieces of .040" strip to it. When dry I sliced off the respective thickness with the razor saw in the miter box. The middle actuator unit is different than the ends. It has two lever boxes attached to a central piece which then has the spring energy box attached to it.

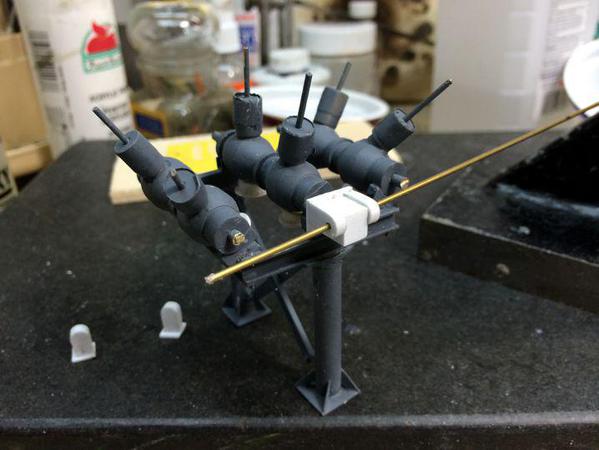

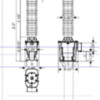

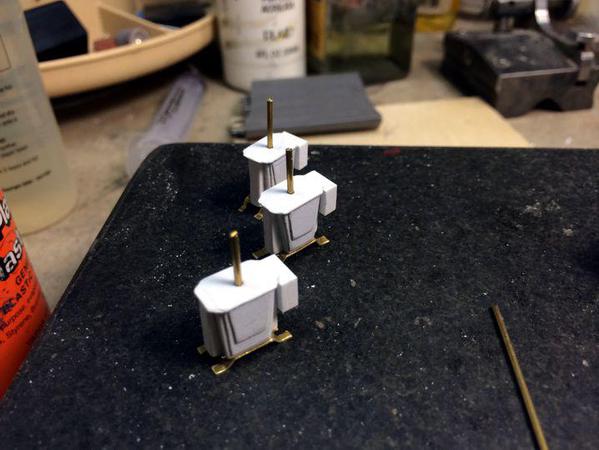

The assembly on the right was my first attempt with the drive shaft running down the center of the middle piece, but after re-checking the drawing I found that the mechanism is off-center lying below the breaker's center line. So I made another one, with the lever boxes offset from the middle piece.

I cross-drilled #55 drill for the cross shaft and tried it on for size.

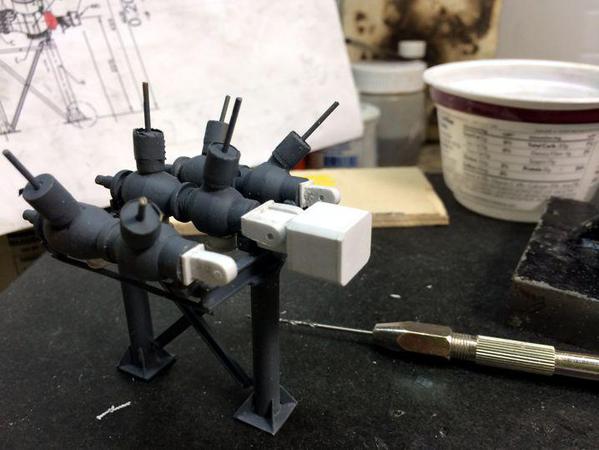

I had to relieve the inner face on the middle piece to properly seat against the breaker body.

The end lever boxes are drilled to accept the shaft sticking out of the breaker and I then installed them on the breaker to get a location for the outboard ends of the cross shaft. While I mounted the breakers onto the base pretty well, there's still some non-alignment which meant I had to spot the shaft's location on each piece.

Between each of these components I'm installing a piece of telescoping brass tube to more closely resemble the enclosure on the real thing.

I then glued the spring engine box to the center piece and took this last picture.

There's a couple of minor surface details on the spring engine box which I'll also add next session. While it's hard to see in today's pictures, I also finished and installed observation windows underneath. I used the punch to make small masking tape circle to mask the windows. Incidentally, the real observation windows are actually off center. And they're smaller than I made them. So I could have just as well used the really off-center ones.

With all this done, I'm still not very happy with it. I found a nice close up of the out board lever boxes and they too are below center. This makes sense because there has to be a bell crank inside to transfer the rotary motion of the cross shaft to linear movement inside the breaker. There's also one more lump on the top that is the pressure relief valve. It's in a tough location to shape so I'm thinking about leaving it off.

As usual, the 1:1 details are always more complex than we'd like them to be in 1:48. You can see the offset, and you can see the subtle shaping of these parts. I have an eye doctor appointment tomorrow that will require dilation drops so there won't be any shop work, but I will be back on the "job" on Friday. Depending on my mood, I see if I can make a more precise rendition of this part of the project. It's also sitting on a round, not square, flange. That's something that I can change also.