Thanks fellas!

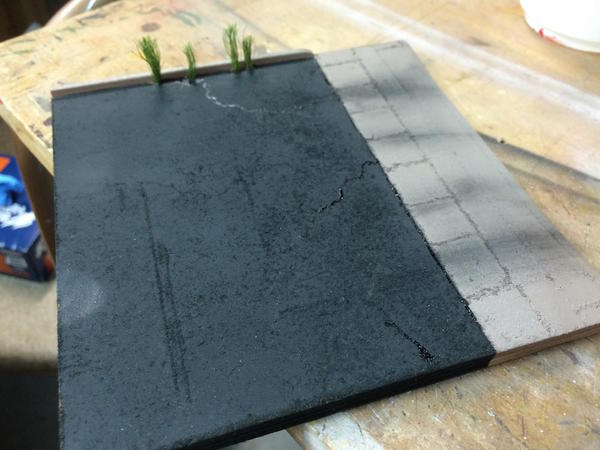

Today I did one thing... with the weather at a wonderful 70+ degrees I sprayed Krylon gray primer on the two hoppers. My wife and I are now on kid watching duty until Sunday, but since they not that young, I may be in the shop tomorrow too and do some final painting. The Airslide is going to be Burlington Northern green with a 1980s BN logo. The covered hopper is going to be Santa Fe brown with the same tagging.

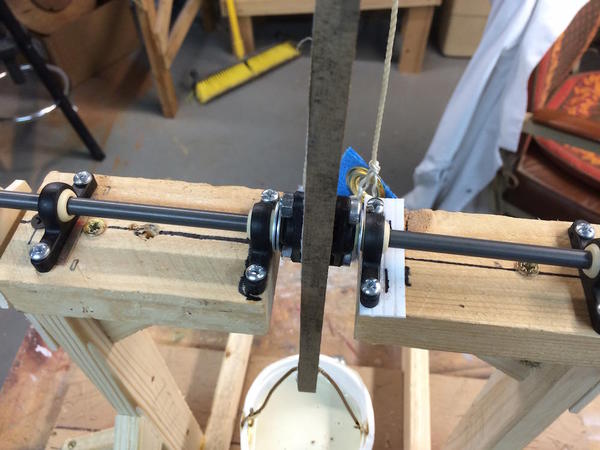

It was impossible to get masking tape to stick to the sintered metal wheel treads so instead I liberally applied a coating of oil so the paint wouldn't stick. If it goes according to plan it should wipe off...famous last words.

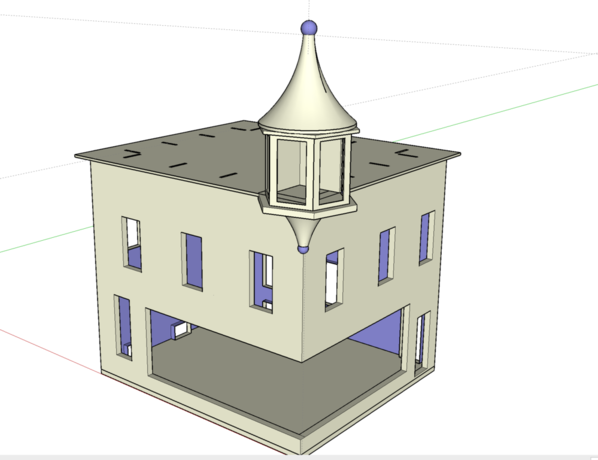

I was interviewed today by the corporate communications person from ABB for inclusion of an article in their internal communications. We had a great discussion and she was frankly amazed that a person of my age could learn some much about a new topic so quickly. She asked if you always have to learn so much about a subject before modeling it. I said it helps. In this case understand how things were arranged and functioned let me make a more substantial model. Plus I had the help of many others including you two with some real-world technical experience.

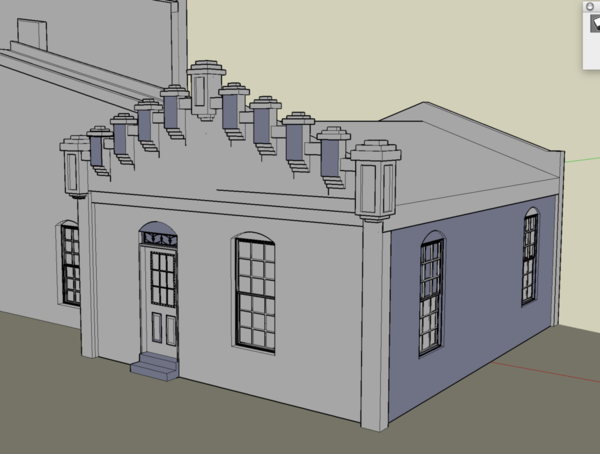

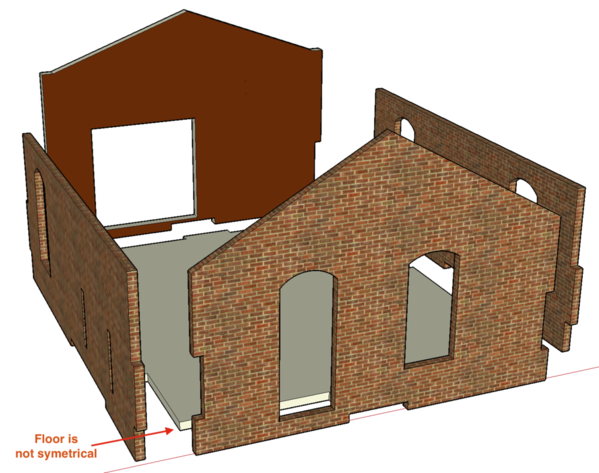

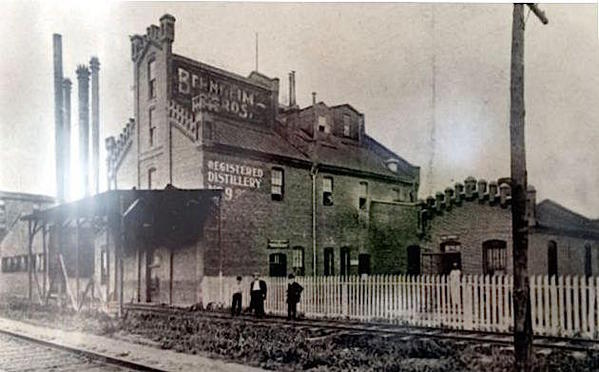

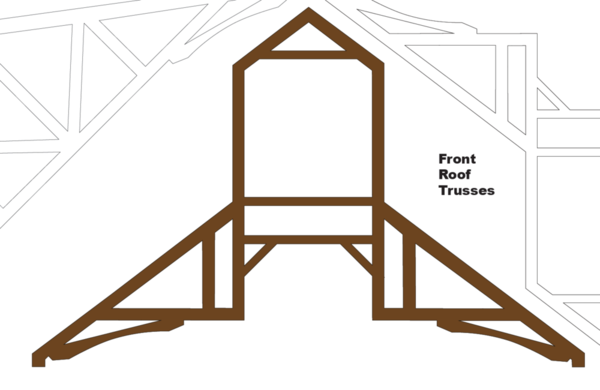

Regarding the distillery. I found out from Andre that all the extra effort I was applying to keep the brick lines off the cutting lines was unnecessary. I made masking lines to keep a 1/32" inch buffer between the bricks .7 pt lines (engraving) and the .3 pt cutting lines. He said the laser will ignore the brick lines butting up against the cutting lines. So I'm going to go back and fix this. These drawings have taken several weeks already. The laser cutting may be fast and accurate, but the drawing creation is slow and labor intensive. The beauty, of course, is you can now cut a thousand and they're all the same.

I am now getting NASA Tech Briefs. In it was a new kind of 3D printer that has been prototyped. Instead of a laser drawing each layer by many, many passes to solidify the polymer, it uses a photosensitive polymer that is UV cure. An entire slice is project upwards through the bath and is focused on a specific layer which immediately solidifies. The next slice's image is projected as the now solidifying object is pulled up one layer's amount. It produces unique parts up to 100 times faster than current technology. They have a lot of work to do on the chemistry, etc., but the concept is genius. Each slice would appear like a view from a cat scan. It will be interesting to see where this all is in 10 years. I would really like a 3D printer and laser cutter in the shop. Nothing could stop me...maniacal laugh, maniacal laugh!