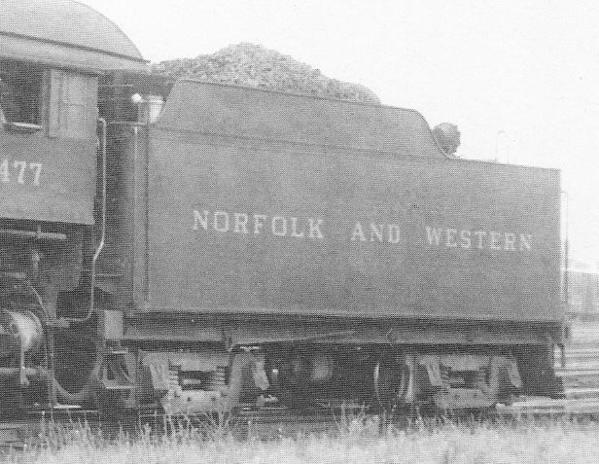

Hi, I bought a new mth 280 switcher. New being a PS3 unit. Now I have bought these in the past and for what they are they were always made fairly nice. However this new version I am amazed to see how much these have now been downgraded. To date it is the absolute cheapest, cheese ball looking tender that I have ever seen. It is really pathetic. It is just so shinny & cheap looking that I don't even want it. I just don't understand why Mike would even approve such a thing. Previous tenders had a dull finish to them which matched the flat black of the engine. This however is so shinny it just looks ridiculous and does such an injustice to an otherwise descent looking power unit.

So the question is, is there any some what easy approach to improve this to perhaps turn it into a jem instead of the ugly duckling that it is ? Now I am not really looking to do the weathering concept on this unit. But I understand that what ever I do will be in the lines of such. Needless to say I am open to any ideas. Thanks in advance...