Originally Posted by GGG:

Of course, I don't really think there is a high demand for this considering all the benefits going to a PS-2 or PS-3 upgrade. G

I currently have a dozen PS-1 locomotives (And several more on my locomotive hit list.), and if they get a command upgrade, it'd be to TMCC, not DCS. And at least 4 of those would only get upgraded if I could keep the sounds. So if someone comes up with a solution to test, I'd be willing to try it out. I have had an idea in mind, and talked to an EE here at work about it, but neither of us have had time to sit down and start looking into detail about it. Some things I've thought about;

-Locomotive still works in conventional.

-Some people like the PSA/FYA (I don't.) so there would need to be a way to trigger them. But if you could it as a loss to get TMCC, you could lock the locomotive in forward before doing the upgrade (Solves the getting out of reset issue.), but then you'd also loose the sounds played when in neutral (And the ability to program the locomotive.).

-Would you be able to control the smoke with the remote, even add John's super chuffer board? Problem here is that I can't think of any way to time the smoke chuff to the PS-1 sounds. Could match the smoke chuff to the wheels, but then being off from the sounds might put some people off.

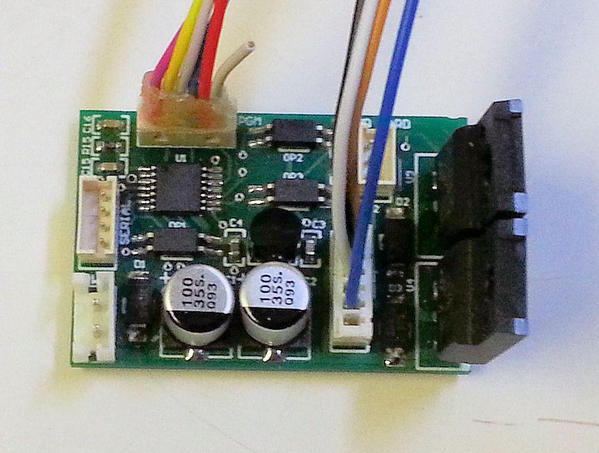

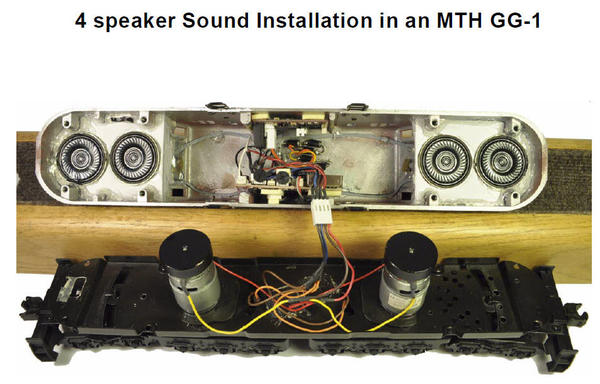

My idea that I shared via email with John a while back was to made a board that the TMCC receiver plugs into that you place between the rollers and the PS-1 boards. In conventional the board passes track power to the PS-1 board set. In command the board varies the AC power and send the DC offsets to the PS-1 boards. Basically the track is like a power brick and the on board TMCC/PS-1 bridge board acts like a PowerHouse. This wouldn't work for small locomotives, but then most the ones I want to keep the sounds on are large locomotives with lots of room in their tenders or body.