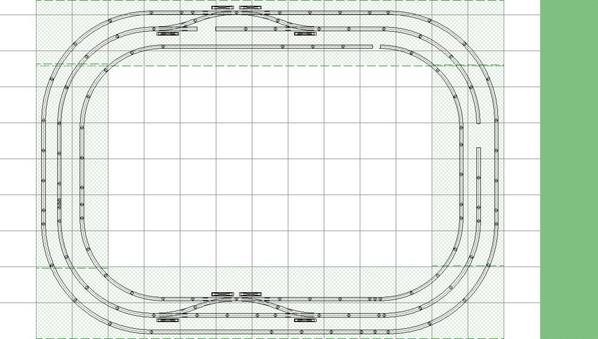

I hate to repeat myself, but if you move the top left switch on the outer loop to the first curved track on the curve side of the upper left switch leading to the next inner loop, you can extend the top siding to have a 3-tier ladder style yard up there. I think the straight part of the switch can be followed by curved tracks to connect to the siding track up there. You may have already tried that and it wouldn't connect or you didn't like it.

Since you have 3 different legs to the outer oval, I'm not sure you really need that double crossover. I know you can use it to avoid a train coming from the other direction, but 4 switches plus the X tracks are not cheap and you already have a passing siding on that leg and 2 other routes you can take to avoid oncoming trains.

At any rate, even though I'm a fan of more loop to loop around the wall style layouts, I think your oval design is coming along nicely.