I am really liking the homemade trolleys I have seen here and on Facebook. It makes me want to to try and delve into making my own. What would be a good passenger car to start with and why?

Joe Gozzo

|

|

I am really liking the homemade trolleys I have seen here and on Facebook. It makes me want to to try and delve into making my own. What would be a good passenger car to start with and why?

Joe Gozzo

Replies sorted oldest to newest

I assume you mean tinplate prewar, Joe? I can't help with an answer, but I have had the same thought, in O gauge in my case, and would like to see examples and ideas as well.

A while back I made a Lionel 60 have couplers and needed some passenger trolley cars I made if this counts.. daniel

Here's my version of Mr. Rogers trolley. This was an interesting project. I used a MTH Bump & Go for motive force. The MTH trolley used AC for the incandescent interior lighting and DC for the front and rear head lights. The interior lighting was constant and powered directly from the rails. A bridge rectifier powered the head lights and motor. Reversing the DC polarity changed trolley direction and head lights. I changed the incandescent interior lighting to LEDs powered by adding another bridge rectifier powered directly from the rails.

The MTH trolley has a slick design for routing power to the lights with no wires between the chassis and shell. The shell incorporates spring contacts which mate with AC and DC pads on the chassis.

You could build a LeBelle kit....

@shorling posted:Here's my version of Mr. Rogers trolley

And here are the instructions for making one! ![]()

https://ogrforum.ogaugerr.com/...gers-tribute-trolley

Mitch

For a Starter project, I'd start in O Gauge. There are a lot more motor possibilities. Once you go to Std, motor candidates are almost zero without major work. You could also do Std narrow gauge. Use an O motor in something like a 600 series passenger car. You have 5 rail already so that may be a fun option.

Steve

@Steve "Papa" Eastman posted:For a Starter project, I'd start in O Gauge. There are a lot more motor possibilities. Once you go to Std, motor candidates are almost zero without major work. You could also do Std narrow gauge. Use an O motor in something like a 600 series passenger car. You have 5 rail already so that may be a fun option.

Steve

Steve , there are the smaller 603-611 and then the larger 611-615. Did you mean something like the 613? What would you use for a motor? And how does one make the ends? Cutting sheet metal? I'd love to see one of these someone had made.

@Steve "Papa" Eastman posted:For a Starter project, I'd start in O Gauge. There are a lot more motor possibilities. Once you go to Std, motor candidates are almost zero without major work. You could also do Std narrow gauge. Use an O motor in something like a 600 series passenger car. You have 5 rail already so that may be a fun option.

Steve

Great advice Steve!

Joe G

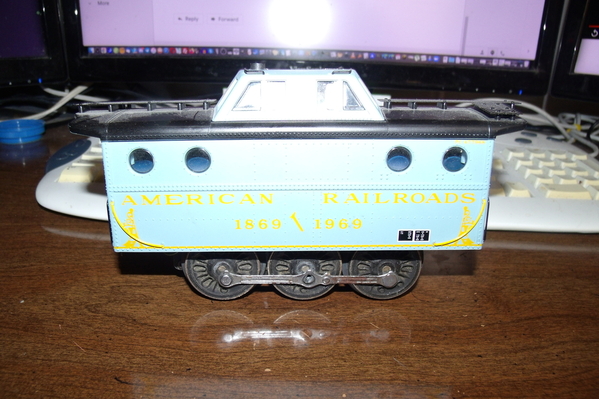

I made a trolley that once done becam

e an MU set . It started with ( I believe) a 309 standard gauge passenger car. And then another . I bought an MTH power truck for one of their pay as you enter trolleys and mounted it on my car . I took on this project because I wanted to see if I could make a live pantograph/ catenary system in standard gauge. It worked !!

e an MU set . It started with ( I believe) a 309 standard gauge passenger car. And then another . I bought an MTH power truck for one of their pay as you enter trolleys and mounted it on my car . I took on this project because I wanted to see if I could make a live pantograph/ catenary system in standard gauge. It worked !!

@Will posted:

I’d go with the larger type. Phugly ones can be picked up cheap. Maybe a couple portholes on the ends for the motorman. A lot of K-Line diesels use a pair of self contained power truck. But one and get two power trucks. They would need to be rectified to run on AC.

Steve

https://youtu.be/cRM1A9u6jqM. Here is a link to one of my videos on YouTube . Please be kind , it was the very first video I ever took to post on YouTube. If you watch it there is a possibility you will get dizzy 🥴! I will say the ending is better because of the speed I had the trolley going .

One thing you might try is mating a tinplate coach with Bowser/Pittman trolley ends and powered floor:

Here's one I got off eBay some years back. The seller mounted the shell on a Vulcan switcher chassis. I added the handrails, headlights and pantographs.

@Miggy asked me about mounting a trolley body on a 675 chassis. Why not take a caboose shell and make it into a boxcab?

Mitch

I found this project in a junk box at the local train shop. Someone had mounted a motor and headlight bracket in an old American Flyer coach apparently thinking "trolley car". I thought it would be fun finish it. The motor wobbled too much (bent axle) so I replaced it with a Marx motor, also used Marx trucks on the trailer car to match the roofline.

-Mark

These are great @JohnnieWalker and @Mark S. and @M. Mitchell Marmel. Thanks for sharing!

Thanks for the tips, @Steve "Papa" Eastman. But I thought K-Line was AC. I guess they were rectified DC motors?

@Will posted:These are great @JohnnieWalker and @Mark S. and @M. Mitchell Marmel. Thanks for sharing!

Thanks for the tips, @Steve "Papa" Eastman. But I thought K-Line was AC. I guess they were rectified DC motors?

They are AC as long as you carry over the reverse board.

Steve

Access to this requires an OGR Forum Supporting Membership