1st post. So Hello! ![]()

I've been trying to layout a plan for my younger kids (and me) to have fun with during the holidays. Clearly, I'm not ahead of the curve this year. I was originally thinking we could start one of the amazing plans I've seen on this amazing site, and expand it year to year - while trying not to spend $1K or more on switches all at once. I've spent an embarrassing amount of time on Scarm trying to recreate many (probably have 20 incomplete plans), but can never get things to line up right. A version of Ken-OScale's NW Minnesota is probably my absolute favorite, but after hours and hours, over several days, trying to recreate, I'm convinced some sort of voodoo or black magic was required for it's creation. Frustration is not an adequate descriptor.

I currently have a a 5.5'x18' double oval with one crossover (super boring). We have a Lionchief Polar Express, but would like to add one or two more "like" trains in the future. I also have an older MTH train, but haven't researched yet if it's compatible with my Lionel setup.

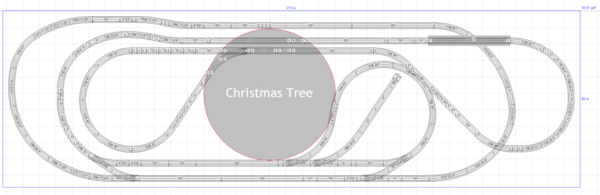

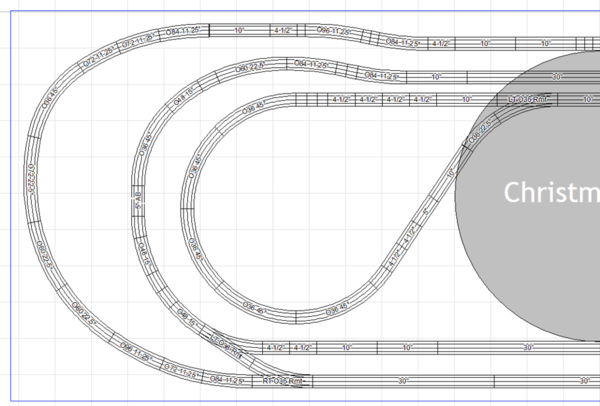

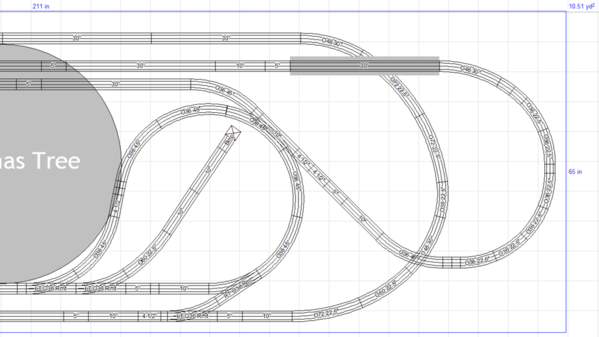

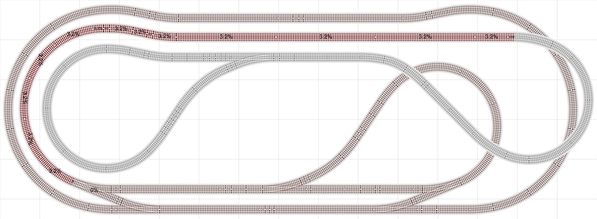

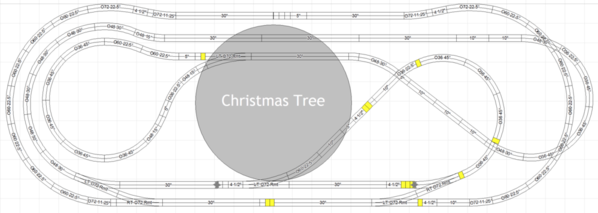

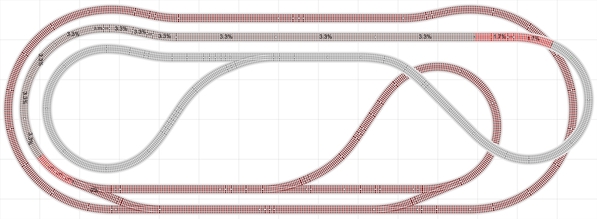

The best plan I can come up with (which started off as one of the AnyRail plans posted on this site) is below. My wife really wanted (demanded ![]() ) to be able to reverse directions, multiple routes, 2 trains at same time, non-symmetrical curves, and elevation with the 30" MTH bridge with Christmas lights. Most importantly, she didn't want it too symmetrical - i.e. she wanted "funky".

) to be able to reverse directions, multiple routes, 2 trains at same time, non-symmetrical curves, and elevation with the 30" MTH bridge with Christmas lights. Most importantly, she didn't want it too symmetrical - i.e. she wanted "funky".

The problem is, this plan looks like rubbish to me. And I had to adjust the Scarm tolerance to 0.11 (2 degrees) so all the pieces would match up (no idea if that's good or bad)... so I'm even not positive it'll even work well.

So, with that all said, anyone have any advice for someone that has no idea at all what they're doing?

Many thanks!

Skip