Originally Posted by 1942guy:

1. minute or two.

2. Cost shouldn't be an issue.

3. Have done of fine soldering, but not with diodes.

4. Trolley's are current MTH models but no Pics at moment.**

* A trolley travels an 80' track back and forth (160') between 2 reversing loops where others wait.

As others point out, the 2 minute specification makes this very interesting.

A few more follow-up questions.

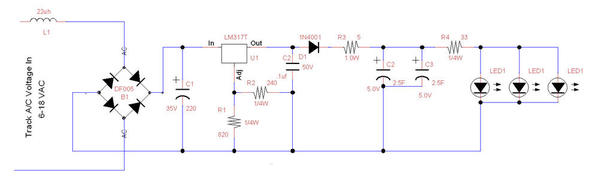

5. So a trolley stops/waits on a reversing loop with no track power for up to 2 minutes. When a trolley runs on powered track, a) what is the minimum "guaranteed" track voltage and b) for how long will that trolley be on powered track before stopping? This line of questioning goes to the ratio of charging vs. discharging time which applies if using some kind of energy storage device (capacitor, battery, momentum flywheel, whatever).

6. What are the MTH stock numbers of these trolleys? There's a rechargeable battery in the MTH Protosound 2 variants if that's what you mean by "current" models. That said, is OK to tap into this battery as a source of backup power? I'm not asking how-to, but as a logistical matter - for example, you may have taken out the PS2 electronics and put in a barebones motor controller.

7. If using stock PS2 electronics, are the trolleys operating conventional-mode (track voltage controls speed) "locked" in forward direction?

8. Read Dale H's method of lowering the voltage to just the motor while keeping a higher voltage available to the PS electronics to keep the lights running. So rather than turning off track voltage to a stop block/section, you would reduce it. You have to think about it for a while and read his linked info. Along the same lines, if you are using stock MTH electronics in conventional-mode with factory-default speed-control turned "on", note there is a small-zone of track voltage where the electronics is ON (lights, sounds, etc.) but the trolley is stopped. It's around 6-8 V on the track. Did you already try this? For example, rather than turning OFF power to the station stop blocks/sections you would apply, say, 7V. The trolley would stop moving but the electronics (lights/sounds) would be active. Variants of this idea may include switching over to DC track power as it might be easier to generate the correct "stop" voltage with DC than AC as current MTH electronics can operate on either.