Does anyone have the installation instructions for the above Horn, Whistle controller?

Thanks in advance.

|

|

Does anyone have the installation instructions for the above Horn, Whistle controller?

Thanks in advance.

Replies sorted oldest to newest

Black wires to transformer... Red wire to center rail, white wire to outside rails.

Don't expect any miracles with this one - it's very low power rated and fragile. A very poor design, and they don't play well on common ground multi-train layouts.

You were exactly right. The control simply did not function on my common ground, multi loop layout. The good news is that Trainz immediately refunded my entire purchase price, including shipping.

@cpasam posted:You were exactly right. The control simply did not function on my common ground, multi loop layout. The good news is that Trainz immediately refunded my entire purchase price, including shipping.

The 5906 will work for your needs.

The 6-5906 has only two wires: do they go directly to the track, via lockon or similar, on the desired loop of my common grounded, multi loop layout ?

Will this operate the horn on my #8773 Southern Pacific diesel ?

Thanks Rob

If I connect one lead from the 5906 to the center rail, and the remaining lead from the 5906 to the A terminal of my ZW, will the pre-existing connection from the A terminal to that track be affected? Will the 5906 remain invisible until the button is pushed?

The 5906 must be connected in series with all power to the center rail / lockon clip 1.

So here’s the problem: now, my A terminal is connected to the track using 14 gauge wire. The wire on the 5906 is probably 20 gauge.

That’s why I was hoping to run the 5906 to a separate lockon from the A post.

@cpasam posted:...20 gauge. That’s why I was hoping to run the 5906 to a separate lockon from the A post.

That IS the drawback. It will have no effect on the train at all if all of the center rail current doesn't go through it.

You can build a heavy-duty version of your own like this.

Would it make sense to rewire the 5906 with 14 or at least 18 gauge wire? Is it even possible to remove the back panel without breaking it?

The loop needs a constant 14-16 volts for the Lion Chief type equipment, so that’s my main concern, since the 5906 needs to be wired in series

@cpasam posted:...possible to remove the back panel without breaking it?

The cases are sonically welded shut and I have been able to bust them open(see sample pic HERE), but the wires are sized to the diodes inside the case anyway(appear to be 4-6 amps), so changing the wires doesn't really accomplish anything. The heavy-duty version like this is probably your best bet.

There isn't anything to activate with this button with LionChief, so are you using this same power district for conventional variable voltage operation as well?

@cpasam posted:Would it make sense to rewire the 5906 with 14 or at least 18 gauge wire? Is it even possible to remove the back panel without breaking it?

The loop needs a constant 14-16 volts for the Lion Chief type equipment, so that’s my main concern, since the 5906 needs to be wired in series

Let's go down your rabbit hole. OK, because this short length of wire is a smaller gauge, yes it has higher resistance. But let's not kid ourselves- it's not like there is even 3 feet of wire here!!! A SHORT distance of lower gauge wire is NOT going to cause a dramatic voltage drop- if even measurable, let alone the fact it's not even enough wire length distance to count for anything to speak of, and the other factor- Lionchief engines are NOT power hogs drawing multiple Amps of current. Again, any voltage drop that would exist- would be a function of both wire length and current drawn. In both cases, we are talking about a big nothingburger.

Part2. Let's take 30 seconds and understand what the bell or whistle controller is: It's nothing more than a Normally Closed switch, and a diode or diodes in parallel. All current is carried by that switch normally under normal operation. Only when you press the button does the diode then bypass the now open circuit switch.

So the limit is just as much what is that switch, what is it's current rating, and which is weaker- the wire or the switch?

Again, you are going down a rabbit hole for no good reason. The reason it's cheap is the switch- and they used matching cheap wire- because that's the limit

Again, your concern of voltage drop is negated in the scenario of running specifically Lionchief engines. Putting the whistle controller in series should not and will not drop the voltage given the short wire length and low current drawn by Lionchief engines.

Now granted- again, we have a KNOWN weakness- so what does matter is do you ALSO then have a fast acting circuit breaker or fuse in series in this circuit from the transformer to protect the wiring and the whistle controller since we have a known current limit situation?

Again, the danger is, do you have an appropriate fuse or breaker in series between the transformer and the whistle button? Right now, the switch inside the button is going to be your fuse in a derailment situation or other short.

@Vernon Barry posted:Right now, the switch inside the button is going to be your fuse in a derailment situation or other short.

So, is the 5906 switch capable of the LionChief 36 watts / 2 amps or is it not? Why would the switch blow out before the 2 amp breaker in the LionChief power supply?

We don't have any information as to what transformer is being used.

@cpasam posted:If I connect one lead from the 5906 to the center rail, and the remaining lead from the 5906 to the A terminal of my ZW, will the pre-existing connection from the A terminal to that track be affected? Will the 5906 remain invisible until the button is pushed?

@ADCX Rob posted:

We don't have any information as to what transformer is being used.

A ZW- hence the obvious concern of adding a fuse or breaker (actually, even if the whistle controller is not used).

@ADCX Rob posted:So, is the 5906 switch capable of the LionChief 36 watts / 2 amps or is it not? Why would the switch blow out before the 2 amp breaker in the LionChief power supply?

@cpasam posted:Will this operate the horn on my #8773 Southern Pacific diesel ?

Also, I'll add you would not want to put that AC only engine, on a DC powered track as that would cause damage to the train since any TRIAC controlled output needs AC to turn off. You could easily burn up electrocouplers or have other major issues. https://www.lionelsupport.com/...-Diesel-8773-6-28242

Page 4 of the manual- do not power with DC.

Last, the guts of a 6-5906 described in this topic https://ogrforum.ogaugerr.com/...nd-activation-button

I would think the switch can handle 2A, I don't know the limit, maybe 3-5A?

Rob,

In addition to Lion Chief which doesn’t need this controller as you said, on this loop I also run a #8773 Southern Pacific diesel in conventional mode for which I hope to use this horn controller.

Before it failed, the whistle controller built into the ZW operated the horn on the 8773 just fine, and that’s what I’m hoping to replicate using this controller.

Thanks to all for your very competent responses.

Great news.

Thanks.

Rob,

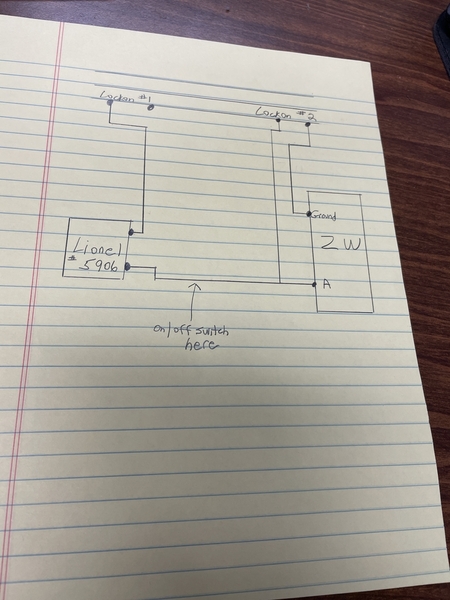

Please pardon the amateur schematic: will this work?

If yes, I could insert an on/off switch before the separate connection from the ZW to the 5906, and only turn it on when I want to use the horn. That way, if the thinner wires on the 5906 are any issue whatsoever, it will only be temporary.

No, the power will take the path of least resistance to ZW clip #1. That must be disconnected.

You can use a SPDT switch to accomplish this.

No, your switch as you drew it, does nothing but prevent the buttons from working.

If you are going to do this- again, #1 add a fuse or breaker- for your own safety and trains, and then #2, if you want to go down this bypass wire, the switch is in series in THAT bypass wire.

@cpasam posted:Please pardon the amateur schematic: will this work?

In a word, no. By directly connecting the ZW to the track in parallel, you've bypassed and nullified any possible effect of the 5906 controller.

If you want to create a temporary bypass, you'll need a single pole double throw (SPDT) switch, with the center terminal connected to the "hot" ZW terminal, one outer terminal connected to the center rail of the track, and the other outer terminal connected to the 5906, otherwise wired as shown on your diagram.

BTW, I agree with the earlier comments that the resistance of the 5906 is almost certainly a non-issue (I have had two wired on one of my layouts, with no evident issues even using a much lower power transformer than your ZW), but if you're obsessive, you can clip the 5906 OEM wires just outside the box and replace them with heavier wiring. I also agree you should add a circuit breaker on every track-powering transformer circuit (don't ask how I know!).

Thanks guys: most informative.

Access to this requires an OGR Forum Supporting Membership