Rick is right on point as far as it getting past the warranty period.

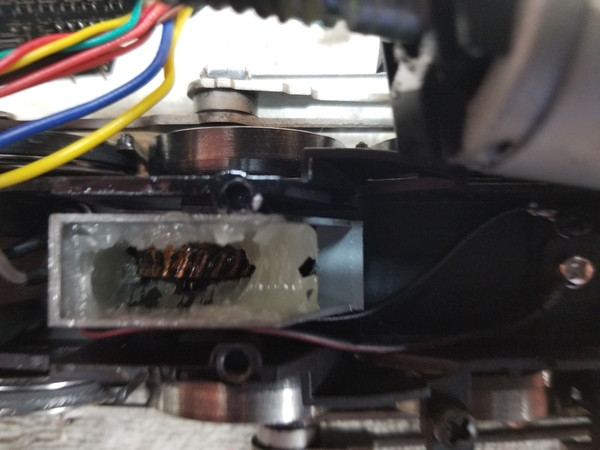

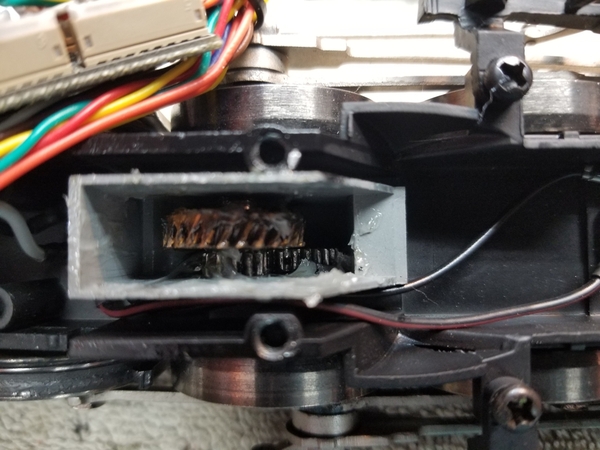

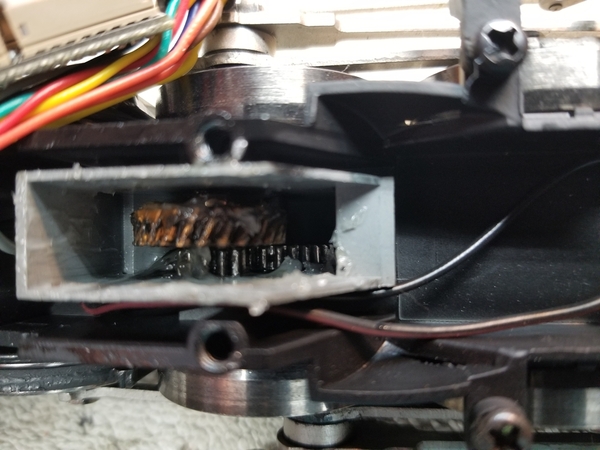

Thing is why would these thing not be discovered by the manufacturer after a while? Yeah, I know that they wouldn't make people aware of this sort of issue because it is quite the sleeper waiting to awaken and all you know what will break loose.

Now, do I think that they did this on purpose? No. I guess they don't have the rigorous testing that they used to. I seem to remember seeing a video somewhere or maybe a clip in a magazine about Lionel(the old company we all remember) testing the you know what out of a quite a number of products. This usually was done to the point of failure, at least whatever I saw/read was stressing.

Do they still do this sort of thing? Well, with what we're seeing I would say not to the point of failure. I think that this is just because of turn around, overhead, all that stuff that makes a company function and profitable.

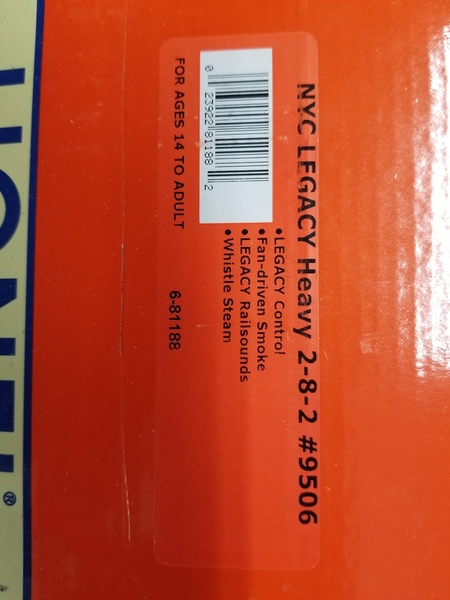

That being said, this still should allow them to put one of their newest things through the meat grinder after it is released to see if there is any issues. Imagine if the Legacy Mogul was out through these tests before it left the factory and after it was shipped to customers. I would say that Lionel would have done a lot better on all those if there had been. What can we do but send our Pennsylvania engines to the great Harmon Yards.