Compiled a list of all the numbers from 2011-2020(since 2011 was the first K4 offering).

So, here is the list. There are a lot of Mike's

K4's Design Flaw Fail!

6-11264 PRR 1361 2011 fail

6-11265 PRR 1330 2011 fail

6-11266 PRR 1361 conventional 2011 fail

6-11331 Polar Railroad conventional 2011 fail

6-11327 PRR 3667 2011 fail

6-11329 PRR 3678 2011 fail

6-11319 Tuscan PRR 5409 2013 fail

6-11320 Tuscan PRR 5436 conventional 2013 fail

6-11330 PRR Polar Railroad #25 2014 fail

6-84116 PRR 5432 LHT 2016 fail

6-84115 PRR 5385 LHT 2016 fail

6-84816 PRR Broadway Limited 5493 2017 fail

1922030 PRR W.G. Harding Funeral 3750 2018 fail

Mike's

6-11278 WP 322 2011 fail

6-11279 WP 327 2011 fail

6-11280 B&O 4507 2011 fail

6-11281 B&O 451 conventional 2011 fail

6-11286 RI 2302 2011 fail

6-11287 RI 2305 conventional 2011 fail

6-11288 T&P 552 2011 fail

6-11289 T&P 557 conventional 2011 fail

6-11282 GN 3125 2011 fail

6-11284 MP 1310 2011 fail

6-11255 C&O 1062 2012 fail

6-11256 NH 3021 2012 fail

6-11257 PRR 8631 2012 fail

6-11258 Southern 4501(Green) 2012 fail

6-11259 UP 2840 2012 fail

6-11260 RG 1207 2012 fail

6-11261 DM&IR 1305 2012 fail

6-11262 Erie 3007 2012 fail

6-81182 L&N 1757 2014 fail

6-81184 P&WV 1152 2014 fail

6-81185 C of NJ 845 2014 fail

6-81186 Frisco 4126 2014 fail

6-81187 C&IM 551 2014 fail

6-81188 NYC 9506 2014 fail

6-81192 GN 3148 2014 fail

6-88179 Pilot 2014 fail

6-81183 MP 1496 2015 fail

6-81181 Southern 4866 2015 fail

6-81189 CB&Q 5509 2015 fail

6-81038 MR 8693 2015 fail

6-81191 Erie 3207 2015 fail

6-81190 WP 334 2015 fail

6-81193 W&LE 6012 2015 fail

6-81180 Black Unlettered 2015 fail

6-81194 NPR 689 2015 fail

6-84532 NPR 587 2017 fail

6-84466 GTW 3734 2017 fail

6-84467 MC 624 2017 fail

6-84468 NYC 5187 2017 fail

6-84469 PRR 9630 2017 fail

6-84470 Southern 4758 2017 fail

6-84465 B&O 4500 2017 fail

6-84471 UP 2537 2017 fail

2131310 ACL 823 2020 fail

2131330 GTW 4070 2020 fail

2131320 Georgia 300 2020 fail

2131340 L&HR 83 2020 fail

2131350 Monon 554 2020 fail

2131360 Frisco 4003 2020 fail

2131370 Southern 4501(Black) 2020 fail

2131380 Wabash 2202 2020 fail

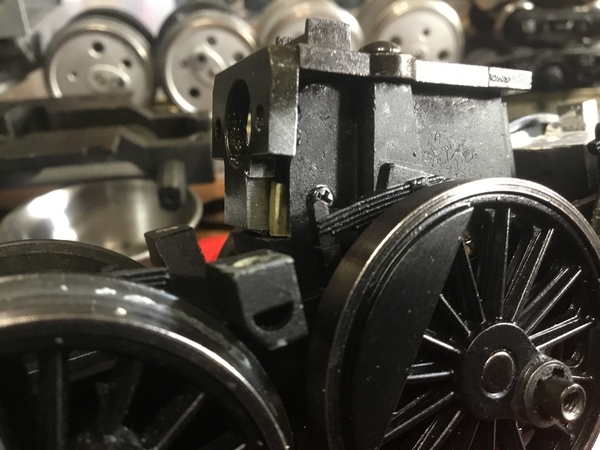

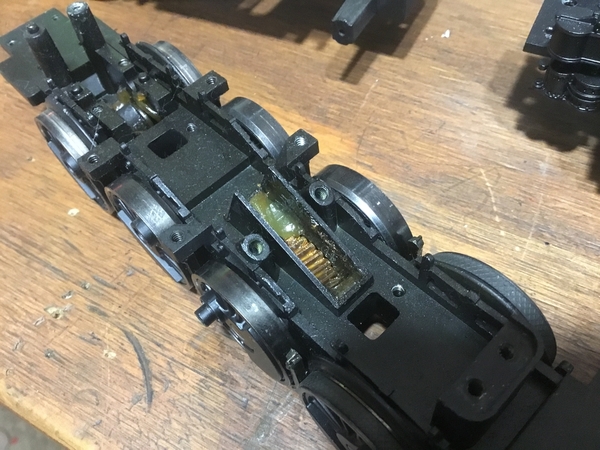

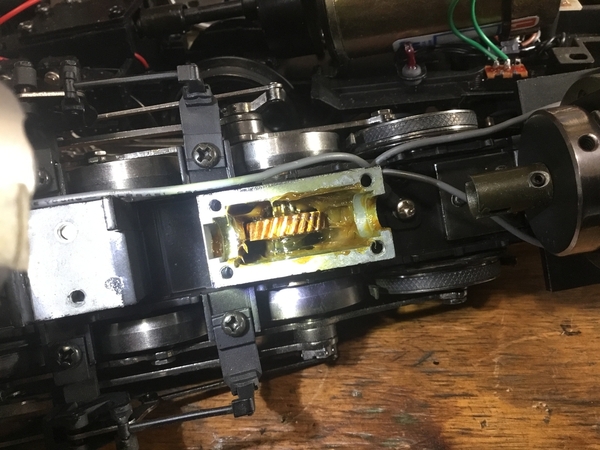

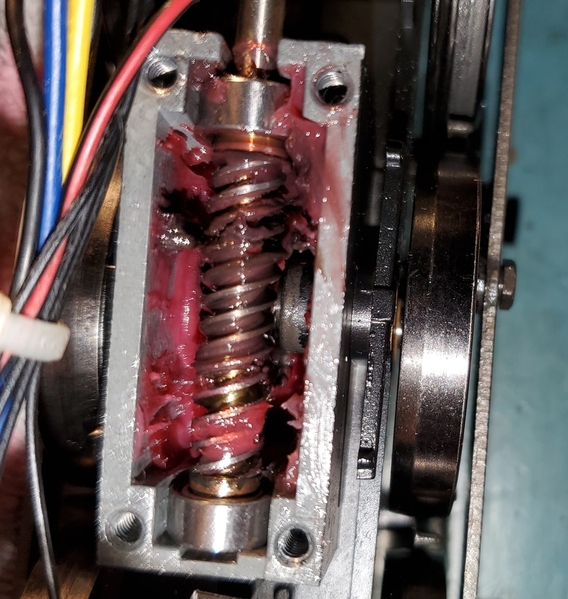

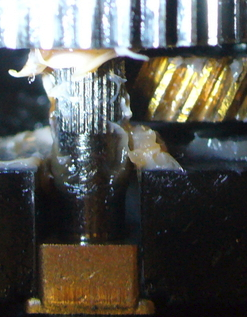

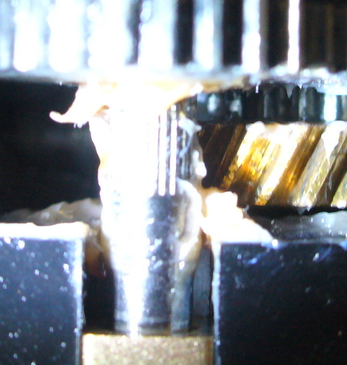

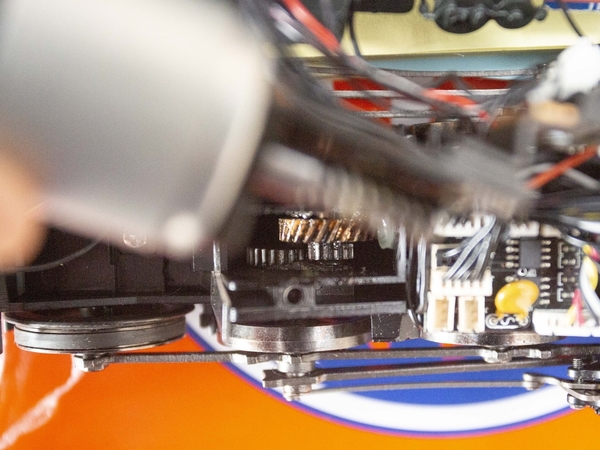

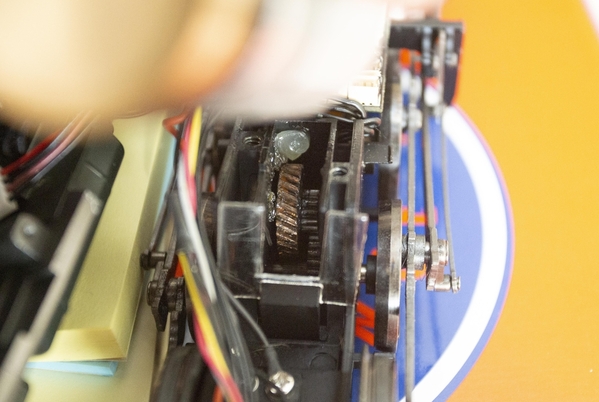

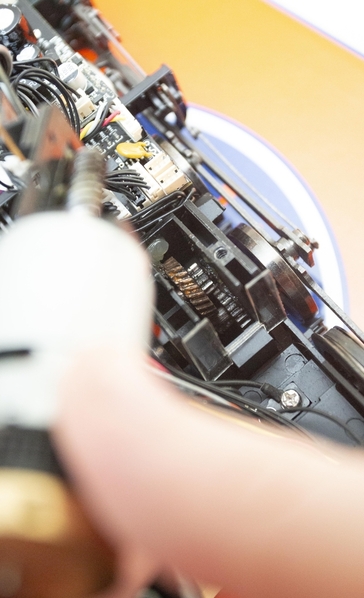

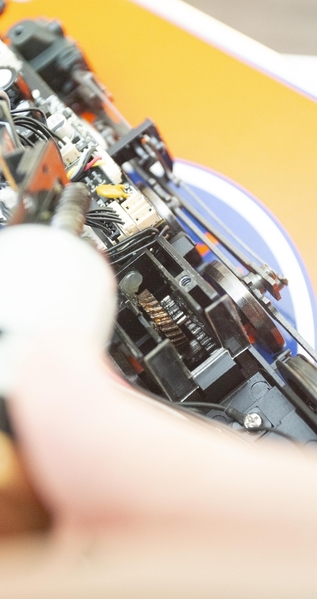

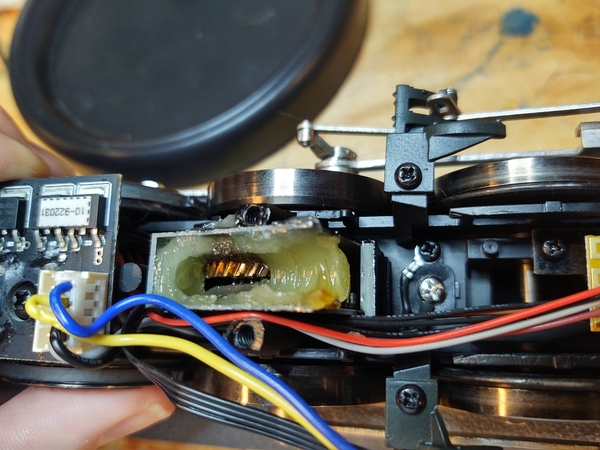

USRA Chassis different from K4 design motor in Firebox connected to worm/gearbox with shaft

Pacific's

6-11338 Alton Limited 657 2012 Pass

6-11335 Blue Comet 832 2012 Pass

6-11334 Cresent Limited 1393 2012 Pass

6-11423 Blue Comet 833 2012 Pass

6-85170 A&WP 290 2018 Pass

6-85171 B&O 5300 2018 Pass

6-85172 R&N 425 2018 Pass

6-85173 NP 2256 2018 Pass

6-85174 Southern 1372 2018 Pass

6-85175 Halloween 1031 2018 Pass

All Pass for 2021 offerings

2122070 Asa Packer Set Lehigh Valley #2023 2021

2122080 Cardinals Set NYC #4899 2021

2122170 Santa Fe Valley Flyer #1369 2021

2131240 Atlantic Coast Line #1504 2021

2131250 GM&O #5296 2021

2131260 Great Northern #1385 2021

2131270 M-K-T #411 2021

2131280 Nickel Plate #168 2021

2131290 Southern Pacific #611 2021

2131300 Union Pacific #3218 2021

2131660 B&O #5236 MR. Muffin's Trains 2021

2131670 Delaware, Lacakawanna & Western #1133 MR. Muffin's Trains 2021

2131680 Louisville & Nashville #280 MR. Muffin's Trains 2021

2131690 Monon #444 MR. Muffin's Trains 2021

2131700 New York Central #3330 MR. Muffin's Trains 2021

H10's

6-84953 PRR Coal Hauler 1773 2018 fail

6-84948 PRR 1288 2018 fail

6-84949 PRSL 6072 2018 fail

6-84951 Bellefonte Central 2018 fail

6-85386 Pennsy Lines West 7109 2018 fail

6-84950 LI 109 2018 fail

6-84952 Weathered PRR 3529 2018 fail

6-85387 Western Allegheny 85 2018 fail

I can edit the list to take stuff off if we need to.

The Pacifics are ok, no actions required. I just haven’t had time to post up my findings,…..

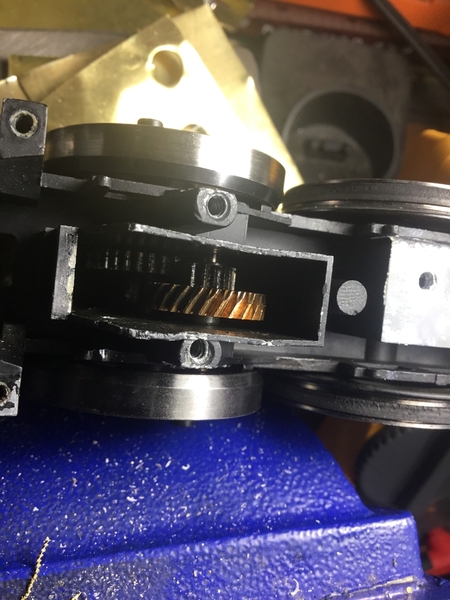

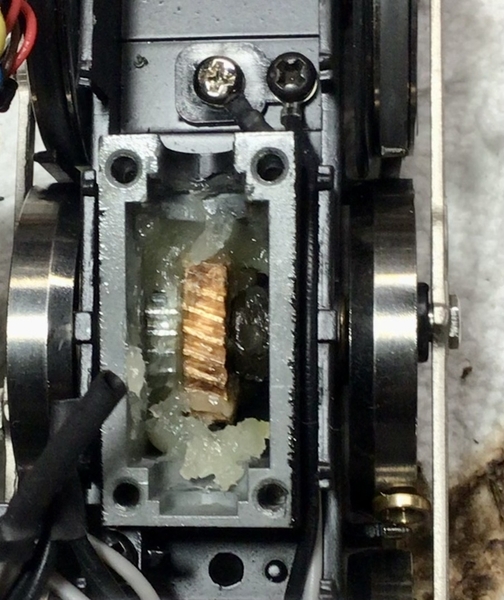

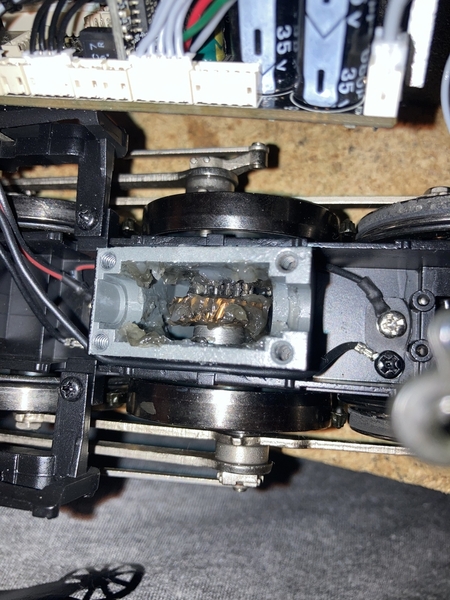

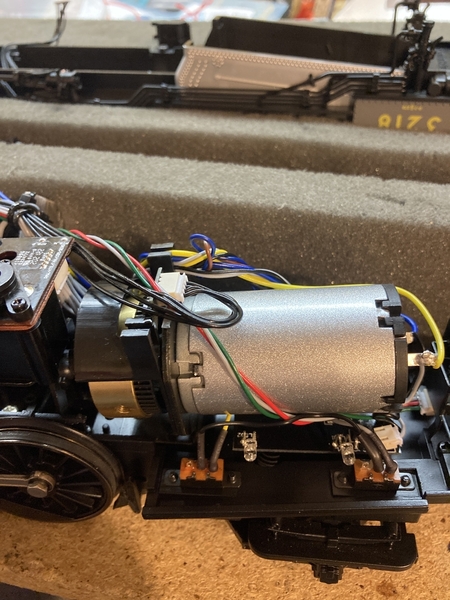

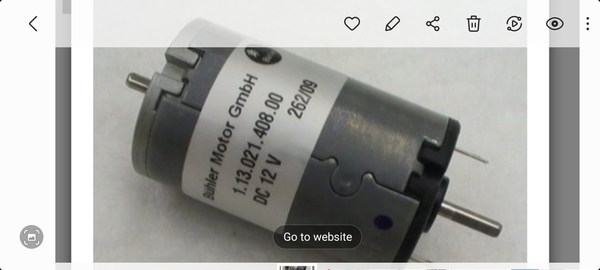

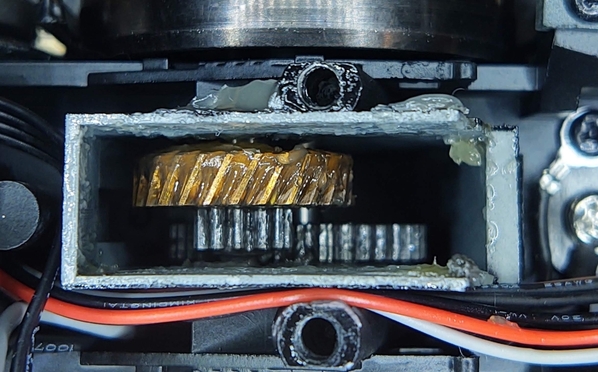

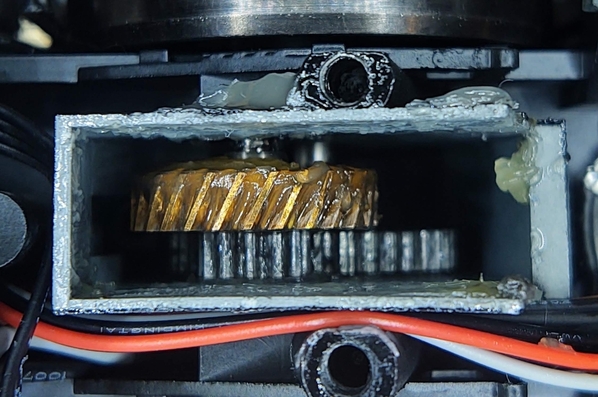

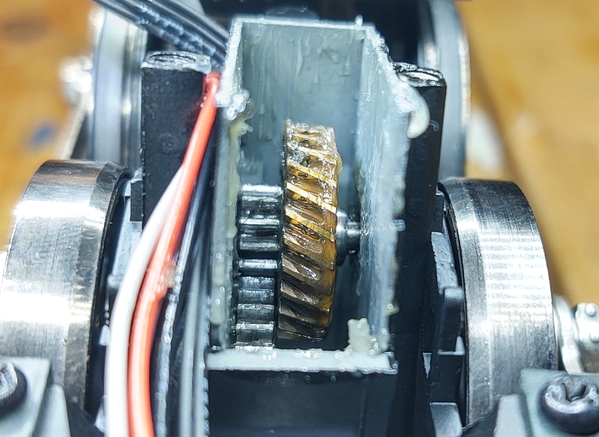

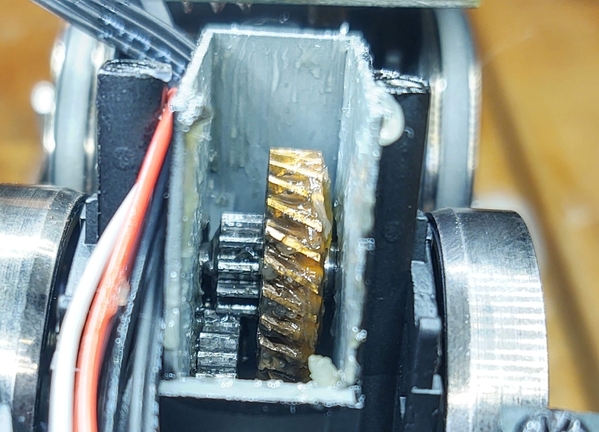

for the record, and let this stand as notes for Dave on his master list, the problem locomotives are those with the forward facing Mabuchi 385 motor. As noted before, the locomotives with the large motors, ( usually Cannons, or Buehlers ) mounted in the cab areas, have a generous black large, nylon spacer that keeps the gear train centered…….

Pat "

I can edit the list to take stuff off if we need to.

My original Post ",Wow, that looks like something I would wind up blowing up if I tried, lol. I have several of the K4 runs and haven't had them out of the box since no track big enough to run them on(unless I carpet run). I don't know if the TMCC 1361 K4 has that issue(wouldn't expect it to be, but what do I know). I guess we'll see more of these getting fixed when you are less busy with work and more engaged in "retirement", haha."