I finally got mine! Long story short Eastside Trains's order was lost just after Christmas and ended up half way across the country. After they found the pallet and 3 weeks later. I finally got to pick up my engine. I took it home, unpacked it, ran it for a bit then immediately took it apart.... like I do.

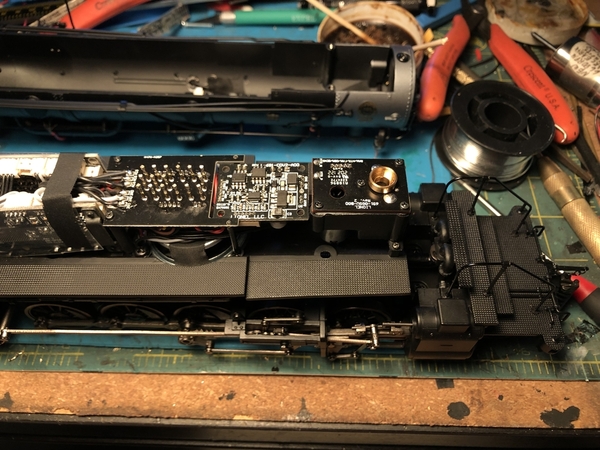

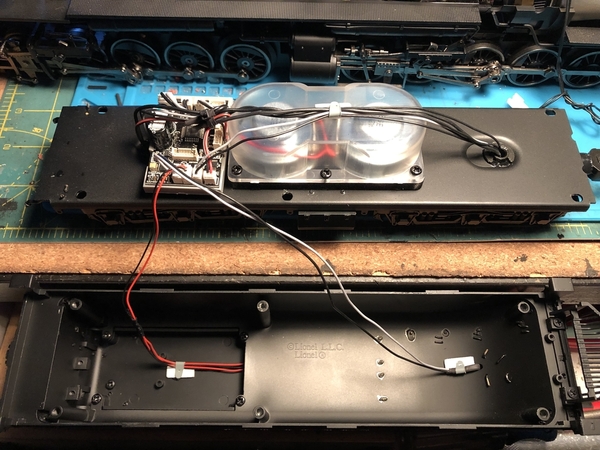

I’m impressed with the engineering that went inside the model. Its stuffed full yet it has to be the cleanest install yet @Dave Olson

Impressions:

- I'm very impressed with how neat everything is laid out. Only 2 wires going to the boiler and frame

- All the wires are tucked under the boards. Nothing exposed to be pinched.

- Lots of pogo-pins making connections between the lower and upper shells. Minimizes lots of wire.

- PCB in the upper shell holding all the switches and lighting connections to minimizes clutter.

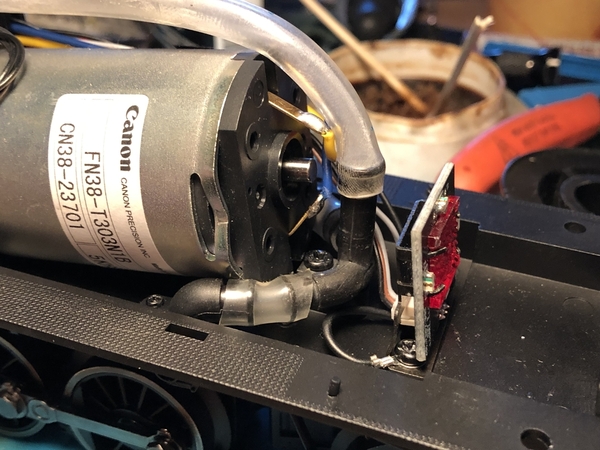

- Engine is fitted with the larger and common Cannon motor (instead of the LGB motor from initial run).

Initial concerns:

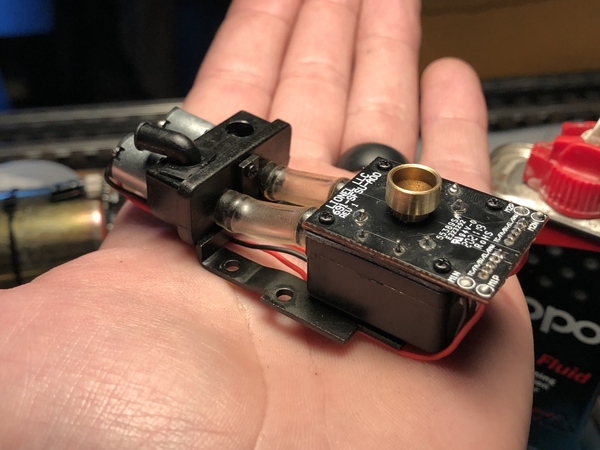

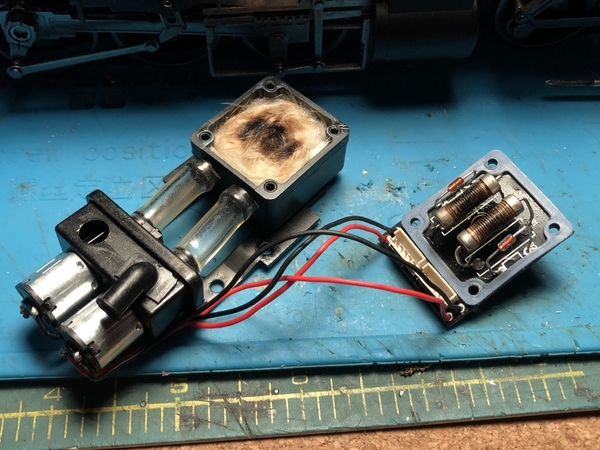

- I'm a little disappointed that they re-used the draw through smoke unit design. The original VL 3000 and CC2 used these smoke units. They work but overtime they cause issues. Since the fans are sucking the vapor out of the bowl (instead of blowing air they become soaked in smoke fluid. This over time will cause the fluid to seep into the fan motor causing it to kill off the motor prematurely. The other thing is since its drawing air through the smoke bowl instead of blowing out the fill hole. There has to be an opening on the smoke bowl to allow air in. Because of that when air isn't moving through the vapor will leak out into the shell. Overtime this coats everything inside the loco with smoke fluid. This in rare cases cause the boards to short out as well.

- Another smoke related thing i've noticed is that they aren't completely sealing to their exhaust holes in the shell. Such as between smoke stack, whistle steam pipe and the blowdown tubs that screw to the the lower shell. During testing with the shell removed I noticed when using the blow down vapor was escaping between joints on the blow down piping. I also noticed vapor coming out of the smoke box door with the shell on. I made adjustments to prevent further leaking in the shell.

Other small "complaints"

- Forward Fireman eccentric crank pin was loose.

- unpainted whistle detail (common thing these days)

- Green Classification LEDs are way to bright...they need to be 50% less bright

- lighted gauges are blank. (OG run was detailed with needles and markings).

- Static in low volume settings.

- When engine is shut down you can hear a "Morse code" in the speakers....super annoying. This is with the new boards.

- Dynamo whine in the sound file should be on or off depending when the lights are on. There shouldn't be dyno whine when the lights are off.

- When braking to a stop, Engine will sometimes come to a stop then have a violent shutter. (noticed with new LCP2 boards)

- Can't over ride cab light on after engine is moving like you could with the RCMC generations.