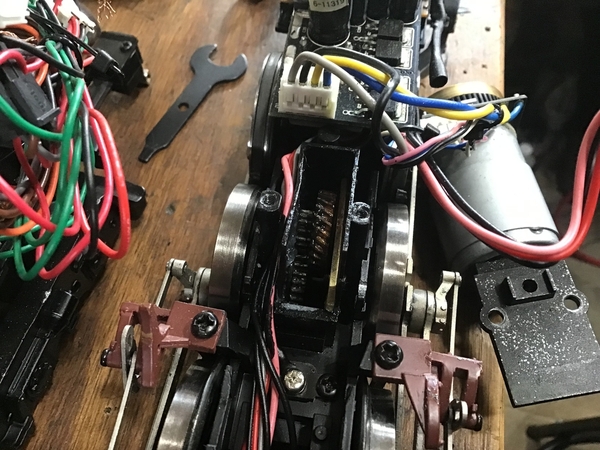

Going back to Pat’s very first post. The piece you show sitting on the Snap On box looks very robust and well machined when you study it close. In the picture of the install with it in place. It looks to be 2 pieces of brass stock. Do you start with a standard set piece and then shim it on a case to case basis

I thought that was the case too - but I think that's just the reflection of the brass bar off of the inner part of the gear box. There is only one brass bar if you study closely.

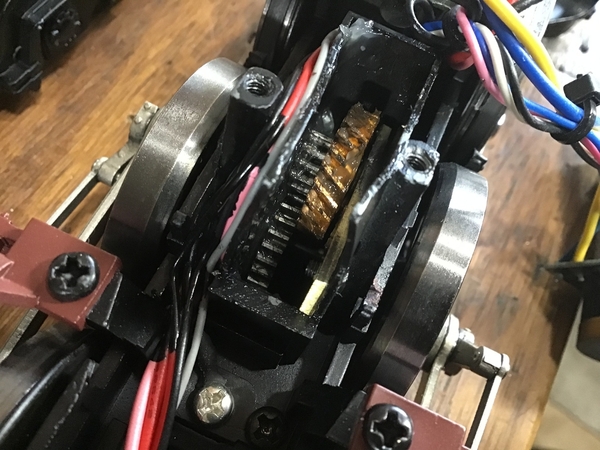

Correct, it is indeed 2 separate pieces at first, the arm is simple brass flat stock, the spacer is machined by yours truly, to a standard size, it’s then press fitted into the arm, then brazed ( brass weld) so it can’t ever come apart,…

Dave, the "two pieces" are 1) flat stock and 2) the "bushing/spacer" that is fitted to the flat brass stock.

..then I sneak up on the bushing width trimming it on the mill for a precise ride……the arms I can crank out as ready to go units, then basically trim to fit,…..as mentioned, I’ve not seen a one size fit all solution in the 4 examples I’ve repaired so far,…..all 4 repairs were successful…..

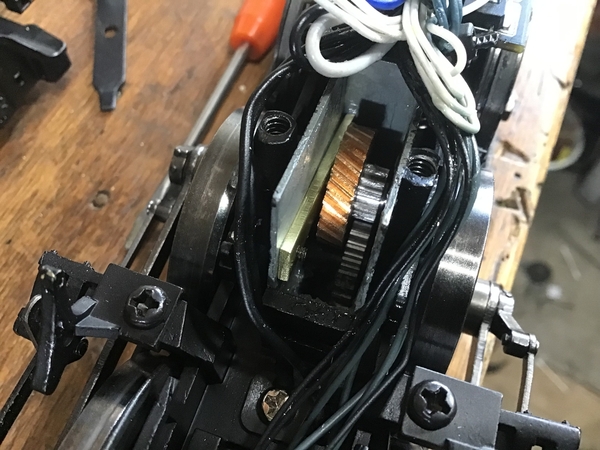

I think this is why GRJ is suggesting the split brass rod. It takes at least one of the variables out of the equation the length of flat stock and where to screw it in. Additionally it shouldn't require modification.

Why couldn't we use a split brass rod with the proper diameter and drop it over the shaft and then squeeze it together so it can't come off the shaft. We just trying to keep the gear from being able to walk over on the shaft, and I can't see why this wouldn't do the job.

The challenge here - and maybe it's not much of one - is that once you squeeze it together, I think a "set screw" of sorts to cinch it together would be a good idea. Ideally it would clamp to the shaft, and rotate with it. It then would ride against inner gearbox wall. Obviously, that will create some friction, but it will be spread over a larger area and only have as much load on it as is caused by the throw out of the worm gear driving the worm wheel. No actual load per se.

The whole reason this failure occurred is because the existing spacer drilled it's way into the shaft bushing. This would eliminate the spacer's "drilling" since it would spin with it and the shaft, and since the new spacer would be larger than the bearing, it couldn't drill into that.

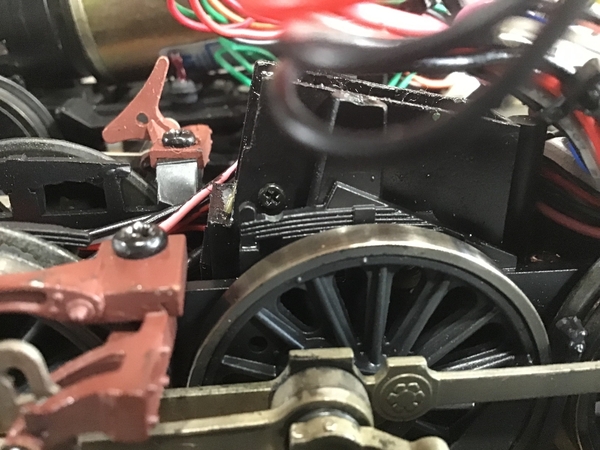

I like this idea GRJ. The only question is... how to balance the new spacer so that it doesn't put too much of a rotational load on the shaft. I'm not sure what sort of RPMs were talking here.